Exception handling method and exception handling method for process control

An exception handling and exception type technology, applied in the direction of comprehensive factory control, general control system, special data processing application, etc., can solve the problems of reducing production capacity, large continuous workload, etc. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Methods of making and using various embodiments of the invention are discussed in detail below. It should be noted, however, that the present invention provides many possible inventive concepts that can be implemented in various specific scopes. These specific examples are only used to illustrate the method of making and using the present invention, but not to limit the scope of the present invention.

[0039] The present invention will be explained by taking an abnormality handling intelligent manufacturing procedure control system under the advanced process control APC as an example, and the present invention is also applicable to abnormality handling in other situations and other process control systems.

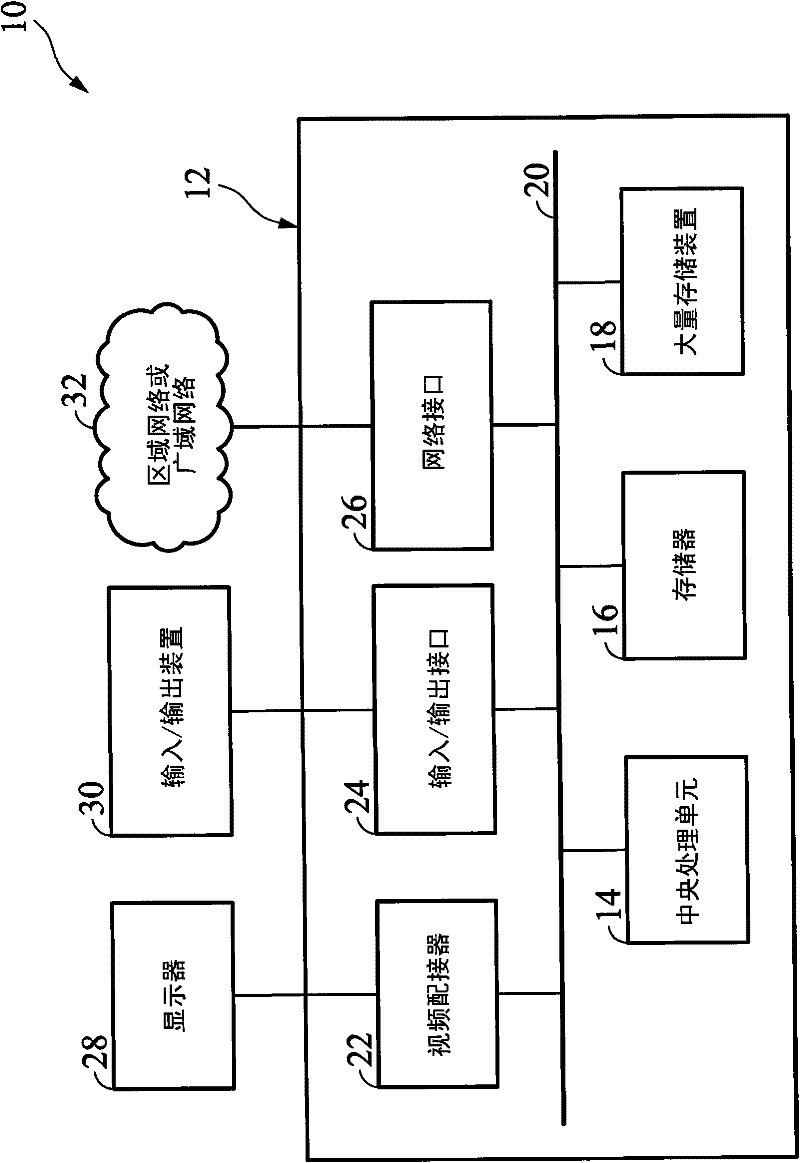

[0040] figure 1 Is a block diagram of a processor system 10, which is an embodiment of the present invention. Processor system 10 is a general purpose computer platform and can be used to implement any or all of the methods discussed herein. The processor system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com