Temperature control system and method for performing single event effect test under same

A technology of single event effect and temperature control system, which is applied in control/regulation system, temperature control, electronic circuit test, etc. It can solve the problem that there is no data related to single particle radiation test, and there is no suitable temperature control system for radiation test equipment, etc. problems, to enhance the flexibility of use, improve anti-interference performance, and eliminate measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

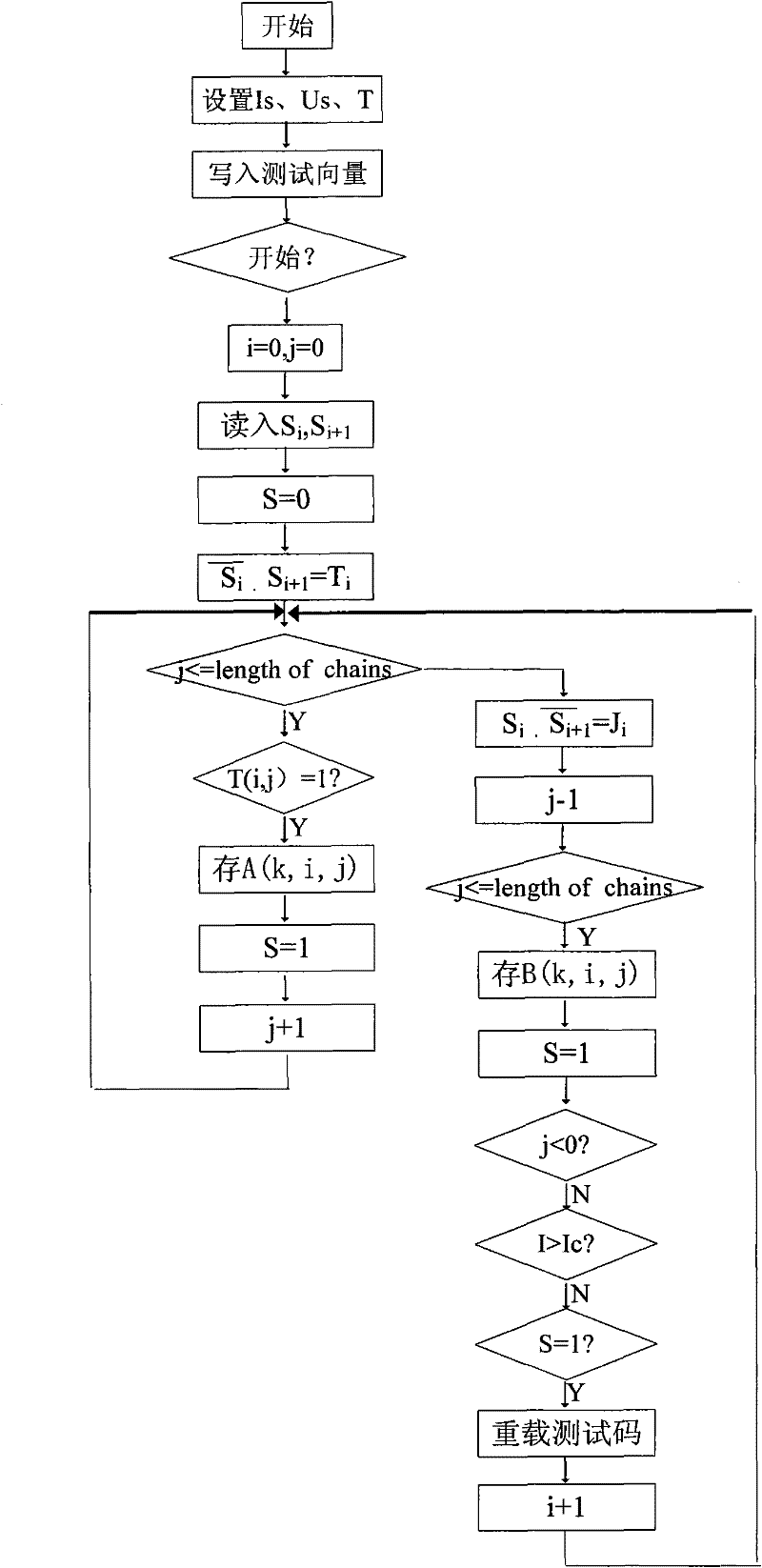

[0048] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

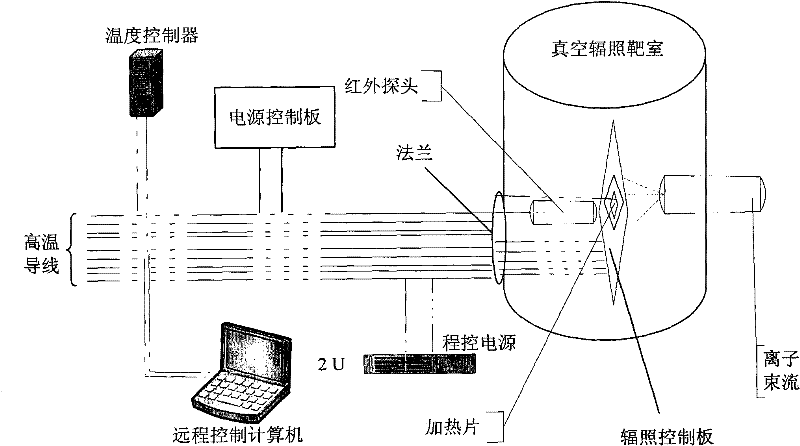

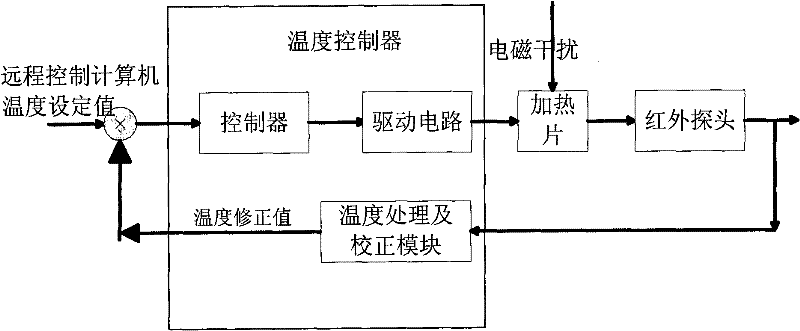

[0049] Such as figure 1 Shown is the structural principle diagram of the temperature control system of the present invention, it can be seen from the figure that the temperature control system includes a remote control computer (host computer), a temperature controller, a heating plate, an infrared probe and a high-temperature wire, and in addition, a vacuum irradiation target chamber is equipped with Irradiation control panel (lower computer), and a program-controlled power supply is installed outside the vacuum irradiation target chamber.

[0050] The temperature controller is connected to the infrared probe and the heating plate respectively through high-temperature wires, and the high-temperature wires connected to the temperature controller and the high-temperature wires connected to the heating plate and the infrared probe realize the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com