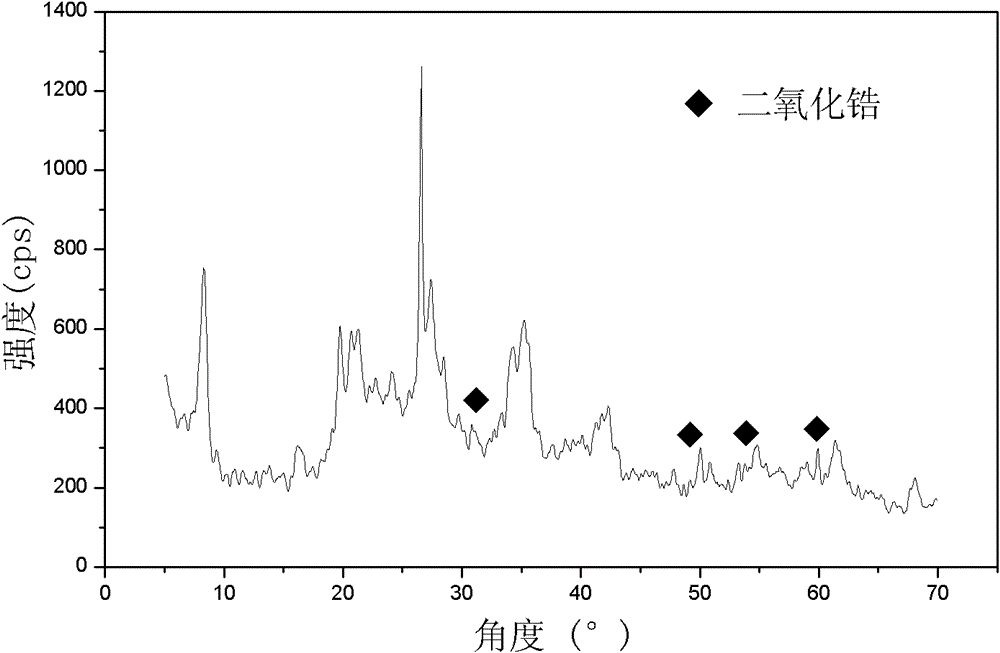

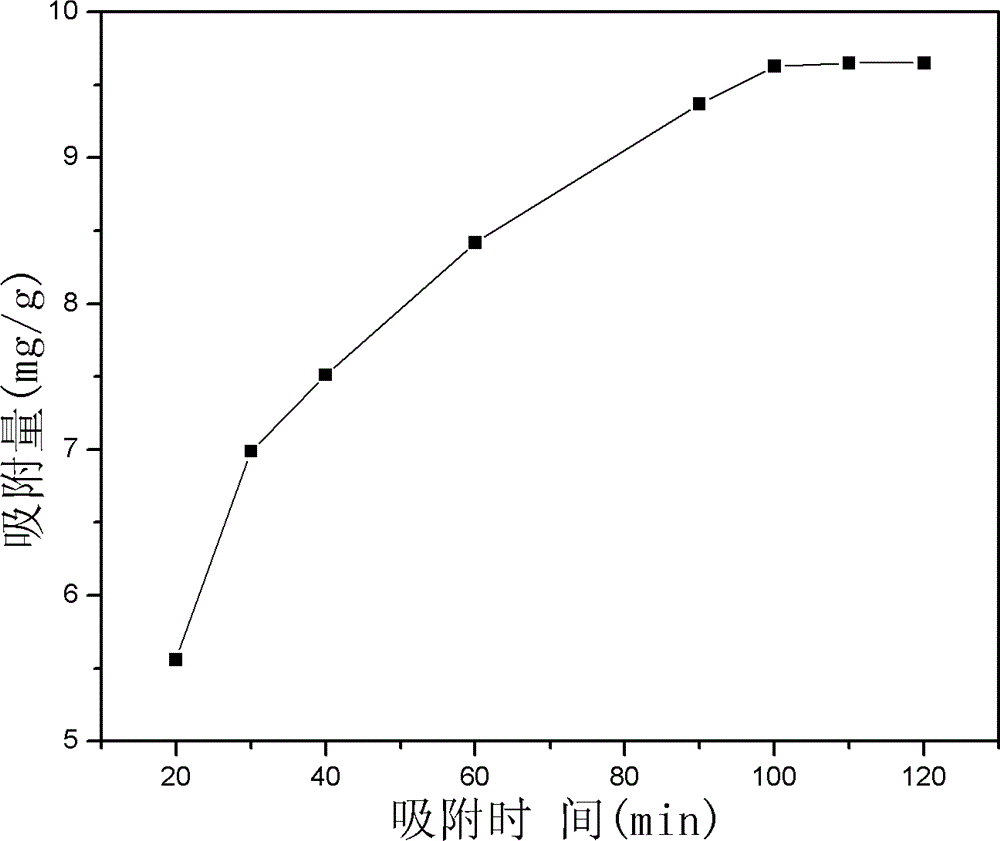

Preparation method of attapulgite/zirconia composite defluorinating material

A zirconia and fluorine material technology, applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment, etc., can solve the problem of attapulgite-based defluorination adsorbents with small adsorption capacity, narrow water treatment range, and preparation technology. complex problems, to achieve the effects of excellent ion exchange performance, fast adsorption rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Selection of raw materials: Weigh 16g of NaOH, add deionized water, and prepare a 0.4mol / L NaOH solution for later use; weigh 13.3g of Al 2 (SO 4 ) 3 18H 2 O, add deionized water to prepare 0.05mol / L Al 2 (SO 4 ) 3 The solution is for subsequent use; according to the ratio of 3: 6 by mass ratio, take 3g of ZrO(NO 3 ) 2 2H 2 Attapulgite after O and 6g sodiumization, standby; The ZrO(NO of 3g 3 ) 2 2H 2 O was added to a beaker filled with 200mL deionized water, ultrasonically dispersed for 10min, aged at a constant temperature of 60°C for 12h, and then left at room temperature for 15h to obtain ZrO(NO 3 ) 2 solution, set aside.

[0027] 2) Weigh 6g of sodium-treated attapulgite, add deionized water to prepare a 5wt% suspension, stir vigorously at 60°C for 10 minutes, and obtain attapulgite suspension for later use.

[0028] 3) The ZrO(NO 3 ) 2 After the solution was added dropwise to the attapulgite suspension, the stirring was continued for 2 hours, and...

Embodiment 2

[0036] 1) Selection of raw materials: Weigh 16g of NaOH, add deionized water to prepare a 0.4mol / L NaOH solution for later use; weigh 13.3g of Al 2 (SO 4 ) 3 18H 2 O, add deionized water to prepare 0.05mol / L Al 2 (SO 4 ) 3 The solution is for subsequent use; according to the ratio of mass ratio 5: 6, take 5g of ZrO(NO 3 ) 2 2H 2 Attapulgite after O and 6g sodiumization, standby; The ZrO(NO of 5g 3 ) 2 2H 2 O was added to a beaker containing 200 mL of deionized water, ultrasonically dispersed for 10 min, aged at a constant temperature of 70 ° C for 12 h, and then left at room temperature for 15 h to obtain ZrO(NO 3 ) 2 solution, set aside.

[0037] 2) Add deionized water to 6 g of sodiumized attapulgite to prepare a 5 wt % suspension, and stir vigorously at 70° C. for 10 minutes to obtain attapulgite suspension for future use.

[0038] 3) The ZrO(NO 3 ) 2 After the solution was added dropwise to the attapulgite suspension, the stirring was continued for 2 hours, ...

Embodiment 3

[0042] 1) Selection of raw materials: Weigh 16g of NaOH, add deionized water, and prepare a 0.4mol / L NaOH solution for later use; weigh 13.3g of Al 2 (SO 4 ) 3 18H 2 O, add deionized water to prepare 0.05mol / L Al 2 (SO 4 ) 3 The solution is for subsequent use; according to the ratio of mass ratio 3: 6, take 3g of ZrO(NO 3 ) 2 2H 2 Attapulgite after O and 6g sodiumization, standby; The ZrO(NO of 3g 3 ) 2 2H 2 O was added to a beaker containing 200 mL of deionized water, ultrasonically dispersed for 10 min, aged at a constant temperature of 65 ° C for 12 h, and then left at room temperature for 15 h to obtain ZrO(NO 3 ) 2 solution, set aside.

[0043] 2) Add deionized water to 6 g of sodiumized attapulgite to prepare a 5 wt % suspension, and stir vigorously at 65° C. for 10 minutes to obtain attapulgite suspension for future use.

[0044] 3) The ZrO(NO 3 ) 2 After the solution was added dropwise to the above attapulgite suspension, the stirring was continued for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com