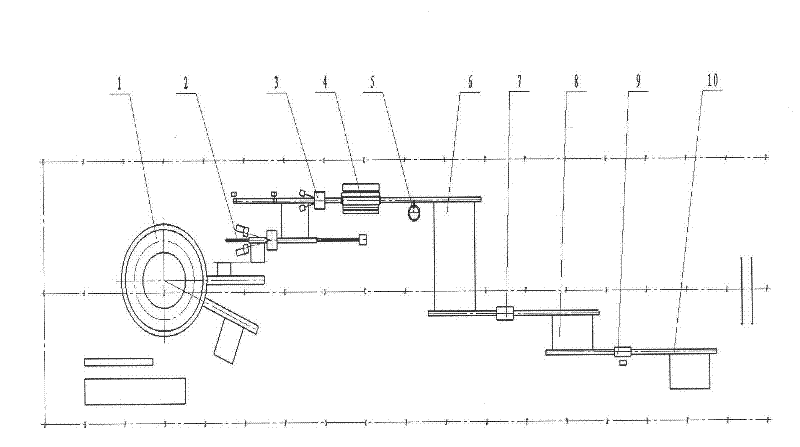

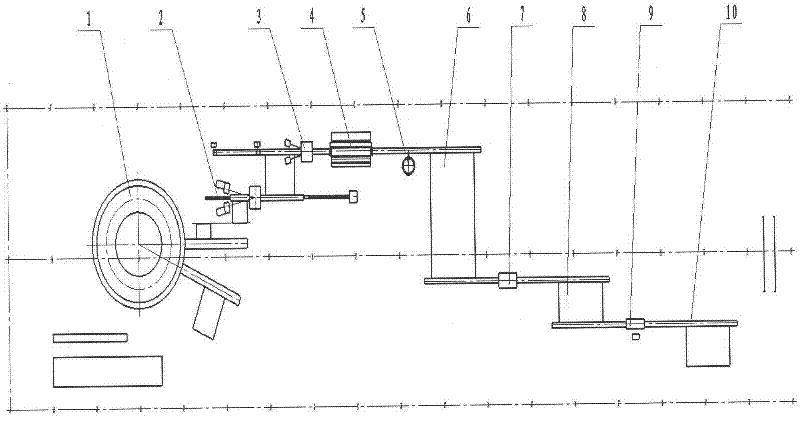

Production process for four-roll planetary hot-rolled tube machine

A production process and hot-rolled tube technology, which is applied in the production process field of a four-roll planetary hot-rolled tube unit, can solve the problems of large shoulder wear, difficult rolling, and the wall thickness of the rolled tube cannot be less than 4 mm, so as to save fuel. , reduce the effect of secondary heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Take the tube blank with a diameter of 160mm and a length of 5m as an example:

[0018] ①Inspection and grinding of the tube blank→②Put the tube blank into a ring furnace and heat it to 1250℃→③Pierce the capillary tube with a diameter of φ165mm and a length of 8m after being pierced by a piercer→④Put through a mandrel→⑤Enter four-roll hot rolling The pipe machine rolls out a waste pipe with a pipe diameter of φ125mm, a length of 50m, and a pipe wall thickness of 3mm → ⑥Entering the strong tension reducing unit of the 29th rack to gradually reduce the diameter and roll out a pipe diameter of φ17.2mm and a length of 800mm , seamless steel pipe with a wall thickness of 2.3mm→⑦Enter the rotary flying saw to cut to length→⑧cooling bed cooling→⑨straightening machine straightening→⑩flat head chamfering, flaw detection, ultrasonic flaw detection, inspection, marking and coloring and Weighing into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com