Method for processing lathe spindle

A processing method and lathe spindle technology, which is applied in the lathe and lathe spindle processing fields, can solve the problems affecting the strength of the spindle, time-consuming and laborious, cumbersome processing, etc., and achieve the effects of material saving, cost reduction and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

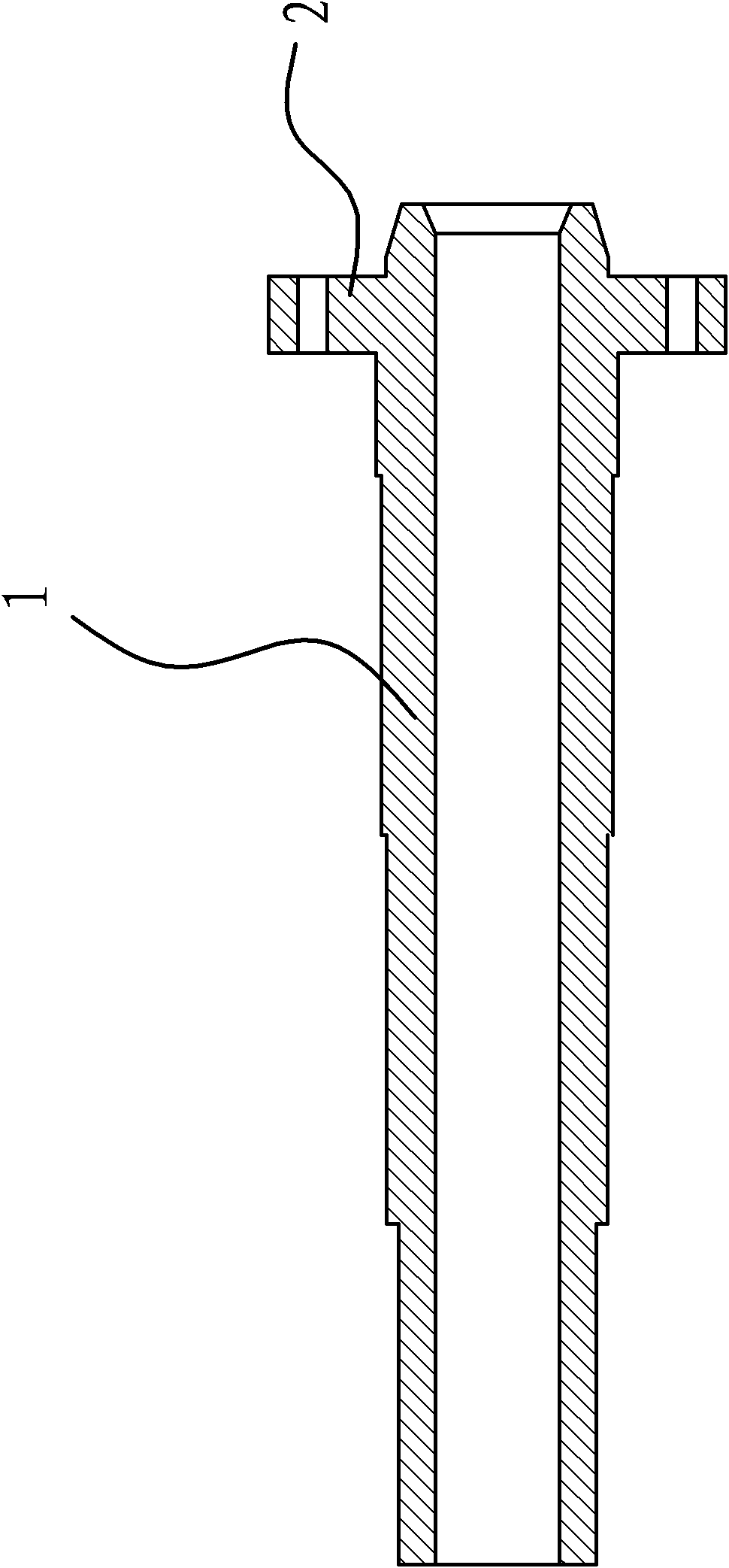

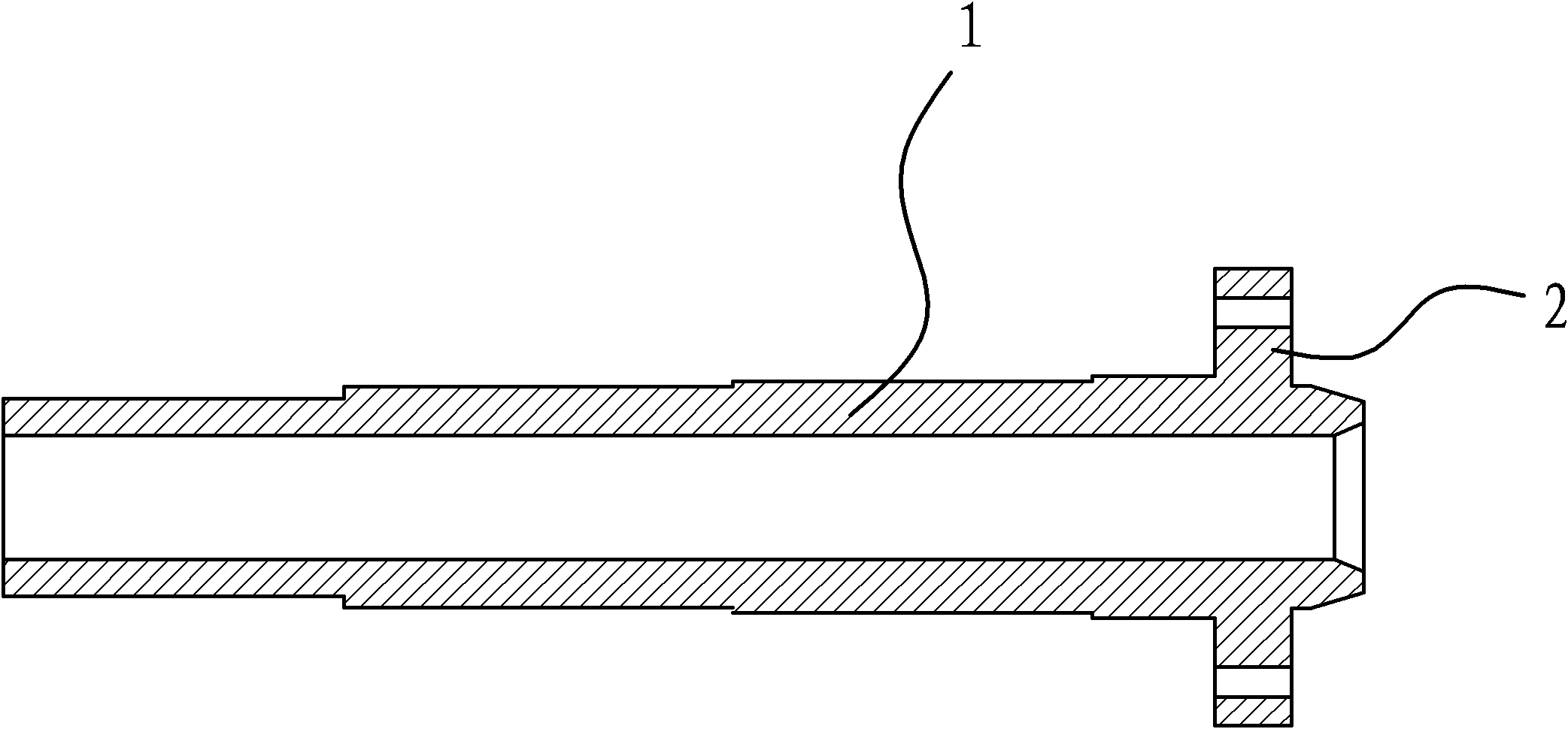

[0037] Such as figure 1 As shown, the main shaft of the lathe includes a cylindrical shaft body 1 and a flange 2 located at the end of the shaft body. The flange 2 protrudes from the end of the shaft body 1 in a ring shape.

[0038] The processing method of this lathe spindle comprises the following steps:

[0039] A. Material selection: Select the raw material of seamless steel pipe with a diameter of 100 mm and a wall thickness of 21 mm, and cut a pipe section that meets the length from the raw material by a sawing machine.

[0040] B. End heating: Heat one end of the above-mentioned pipe section to 750°C by electric heating.

[0041] C. End forging: place the heated pipe section in the positioning mold and make the heated end of the pipe section protrude from the positioning mold. There is a forming mold on the forging equipment. After heating, the heated end of the pipe section extends out of the positioning mold, and the forging equipment moves At the same time, the hea...

Embodiment 2

[0048] The processing method of this embodiment is basically the same as that of the embodiment, except that: in step A, the seamless steel pipe material with a diameter of 110 mm and a wall thickness of 18 mm is selected; in step B, the first heating temperature of the pipe section is 1070 ° C, and The secondary heating temperature is 1060°C, and the forging equipment is a 45-ton forging bed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com