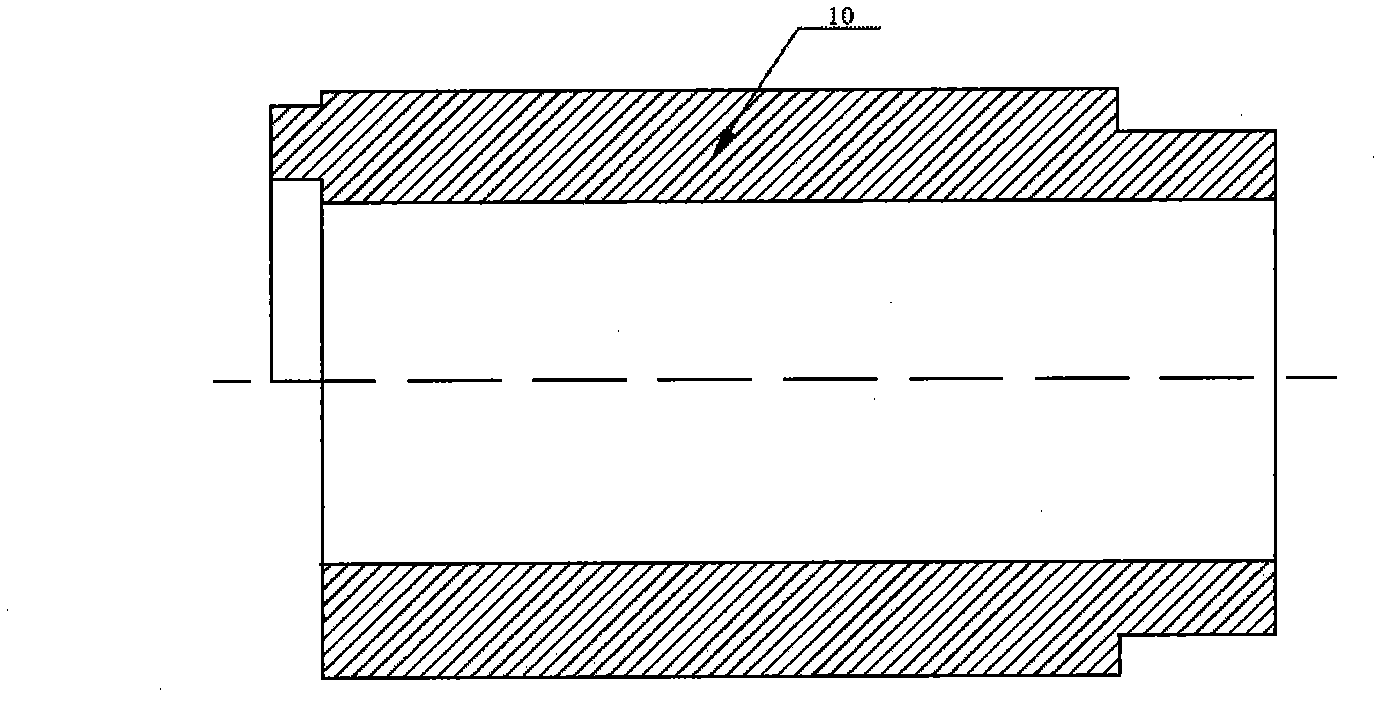

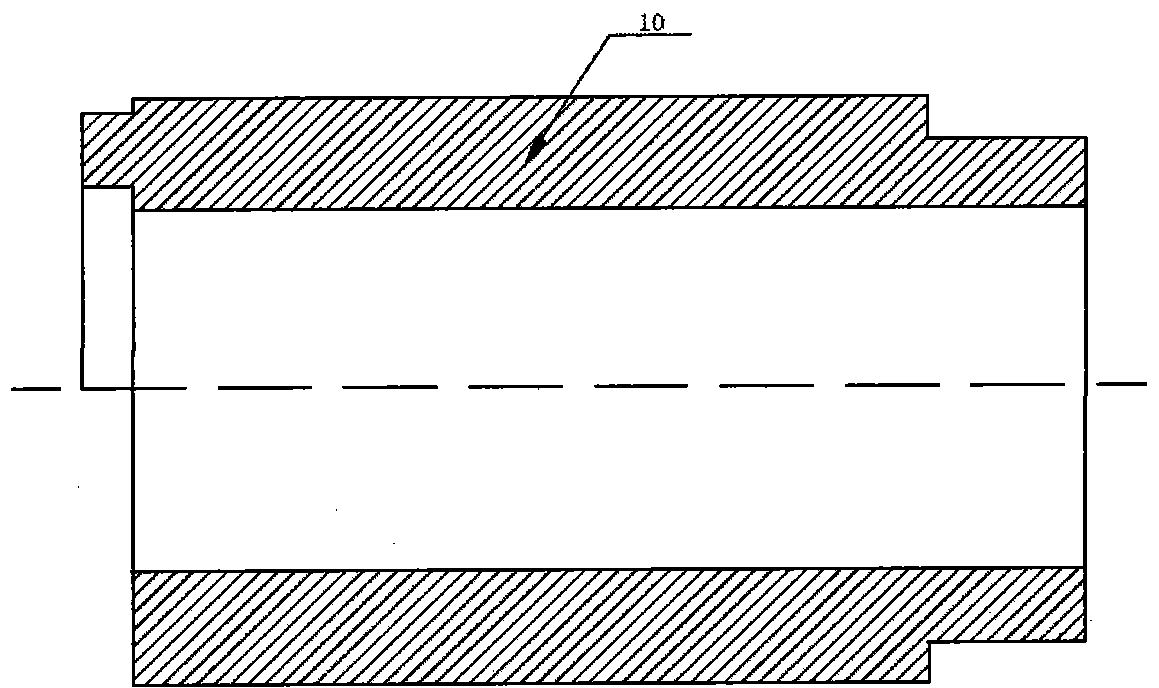

Process for machining retaining ring forged piece of wind driven generator

A wind power generator and processing technology, applied in the direction of engine components, mechanical equipment, etc., can solve the difficult to ensure the use of retaining ring forgings in wind power generators, and the strength performance cannot meet the use of retaining ring forgings in wind power generators It is difficult to meet the requirements of the use of wind turbine ring guards, etc., to achieve the effect of refinement, not easy to be magnetized, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention is a processing technology for a wind power generator retaining ring forging, and the processing technology includes the following process steps:

[0033] The first step: select 1Mn18Cr18N steel as the raw material for the production of retaining ring forgings;

[0034] Step 2: Melting the raw materials in an electric furnace, and casting the smelted molten steel into billets;

[0035] Step 3: Electroslag remelting is performed on the cooled billet;

[0036] The fourth step: recrystallize the molten steel after electroslag remelting to make steel ingots;

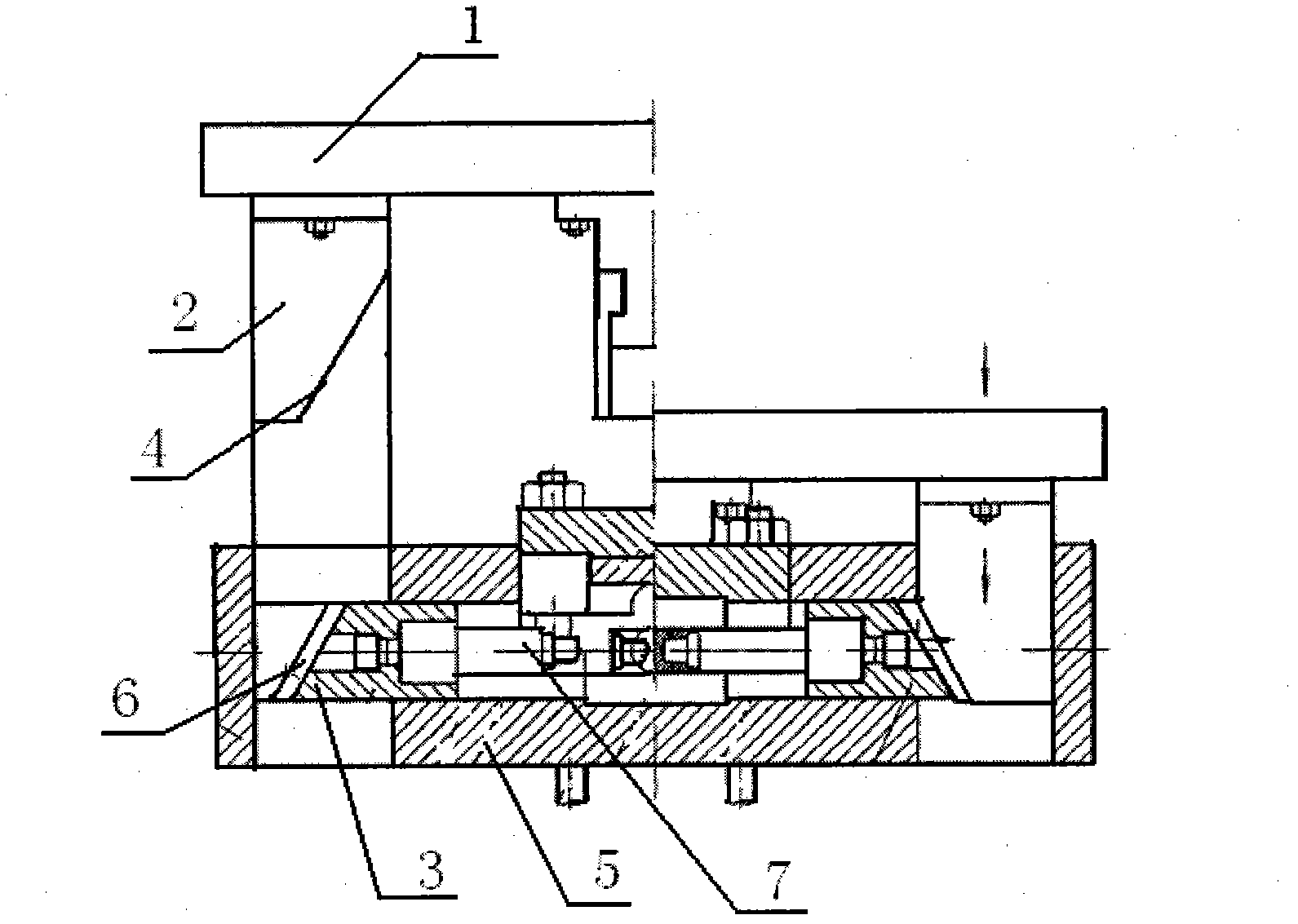

[0037] Step 5: Heating the cooled ingot for forging;

[0038] Step 6: Perform solution heat treatment on the forged forging;

[0039] Step 7: Perform cold expansion forming treatment on the forging after solid solution heat treatment;

[0040] Step 8: Carry out the mechanical performance test of the cold expansion treated forging;

[0041] Step 9: Finish the qualified workpiece to make motor...

Embodiment 2

[0044] On the basis of the above-mentioned embodiment 1, a preferred embodiment of the present invention is that in the fifth step of the forging process, the steel ingot is first heated to about 1200 degrees, and then the heated steel ingot is thickened and drawn by a forging press. Long, punching, reaming and flat forging processes.

Embodiment 3

[0046] On the basis of the above-mentioned embodiment 2, a further preferred embodiment of the present invention is that in the S6 solution heat treatment process, the forging is heated to a high-temperature single-phase region and maintained at a constant temperature, so that the excess phase is fully dissolved into the solid solution, and then the The forging is rapidly cooled in water to obtain a supersaturated solid solution forging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com