Relief angle adjustable device for automatic grinding of arc-edge diamond lathe tool

A grinding device and diamond technology, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low production efficiency, difficulty in diamond turning blade shape accuracy and tool angle, and greater influence of human subjective factors, so as to avoid The effect of secondary clamping error, reducing production cost and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

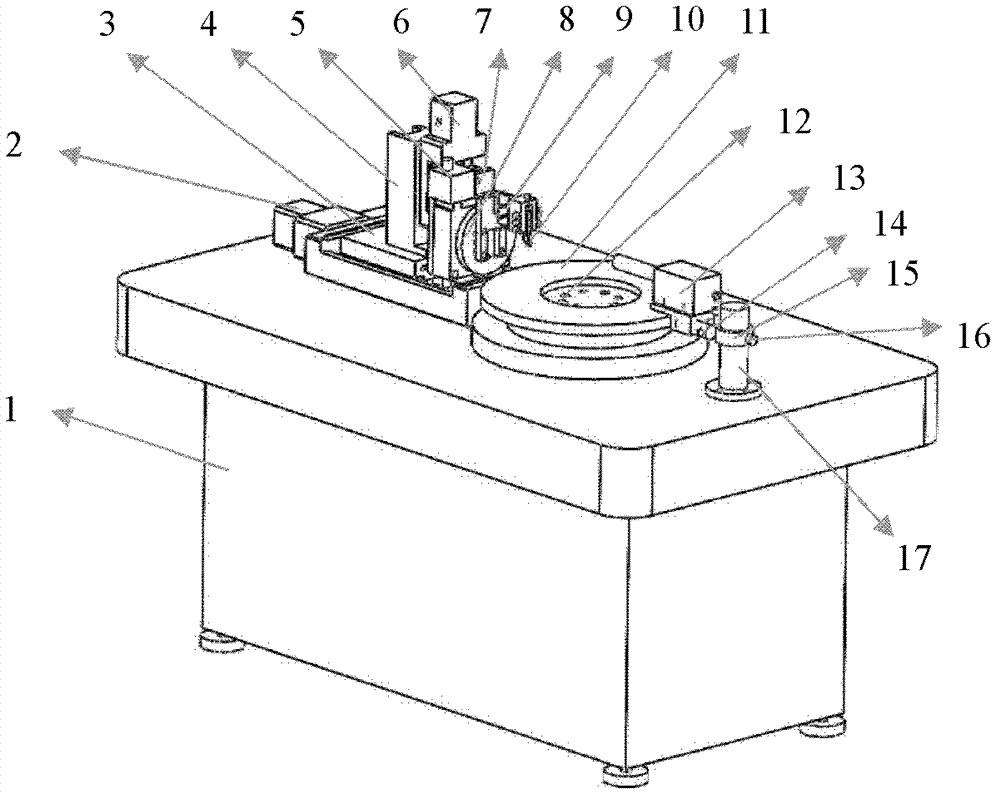

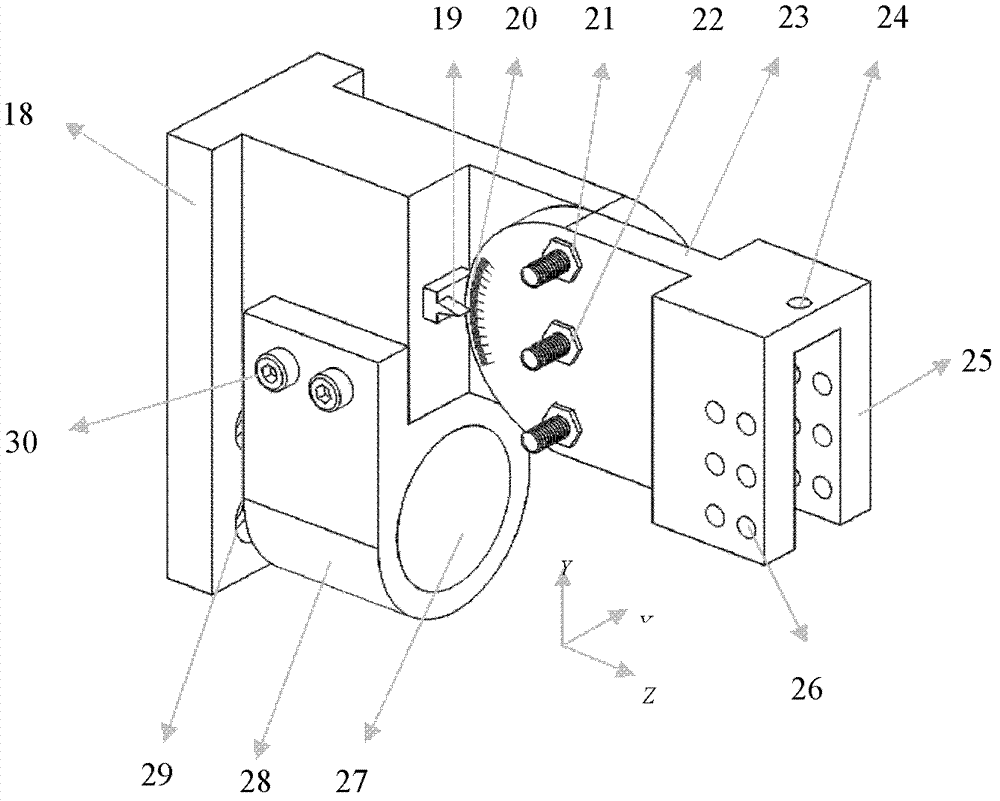

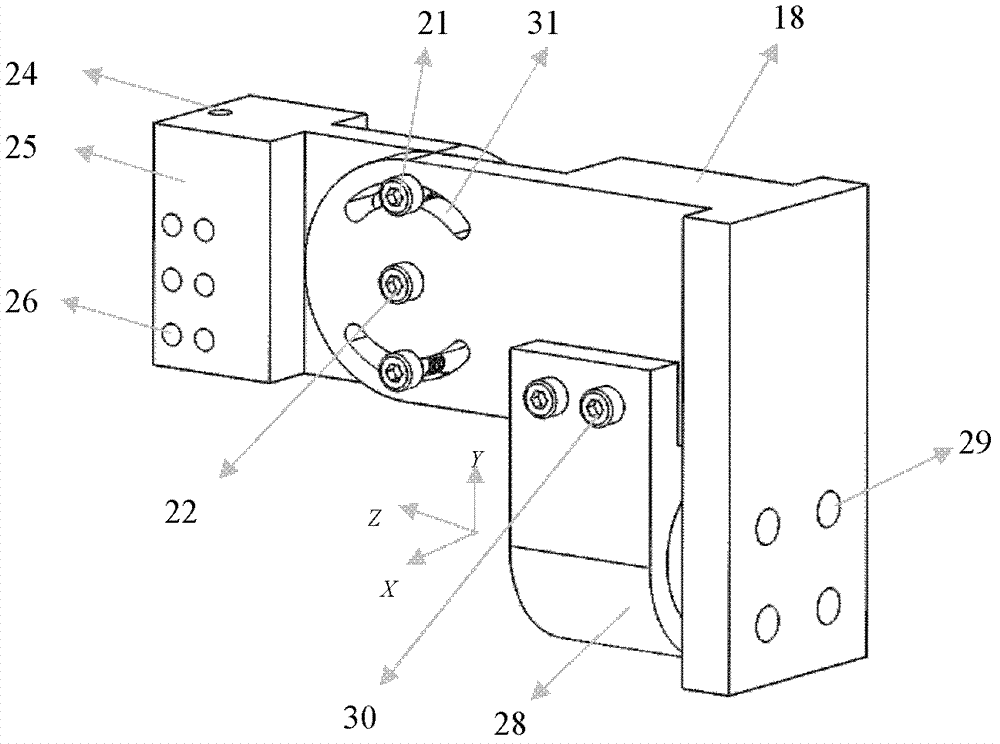

[0014] The invention is a novel diamond turning tool manufacturing device invented based on the diamond turning tool shape creation mechanism and the material properties of diamond. The shown device consists of a base 1, a transverse feed device including a transverse feed table 3 and a drive motor 2, a longitudinal feed device including a longitudinal feed table 7 and a drive motor 6, and a swing device including a swing table 8 It is composed of a drive motor 5 connected to the swing table 8, an adjustable back angle clamp 10, a grinding disc (or end face grinding wheel) 11, a CCD (charge coupled device) camera 13, and a computer. The said transverse feed device and longitudinal structure device can adopt structures such as lead screw nut slide table and also can adopt the structure of cylinder push rod slide table.

[0015] like figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com