Polishing grinder

A polishing grinding and aperture technology, applied in the direction of optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of insufficient grinding amount, long processing time, medium and high surface shape, etc., and achieve the purpose of suppressing the change of the surface shape of the abrasive tool, Prevents scratches on the surface of parts and improves polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

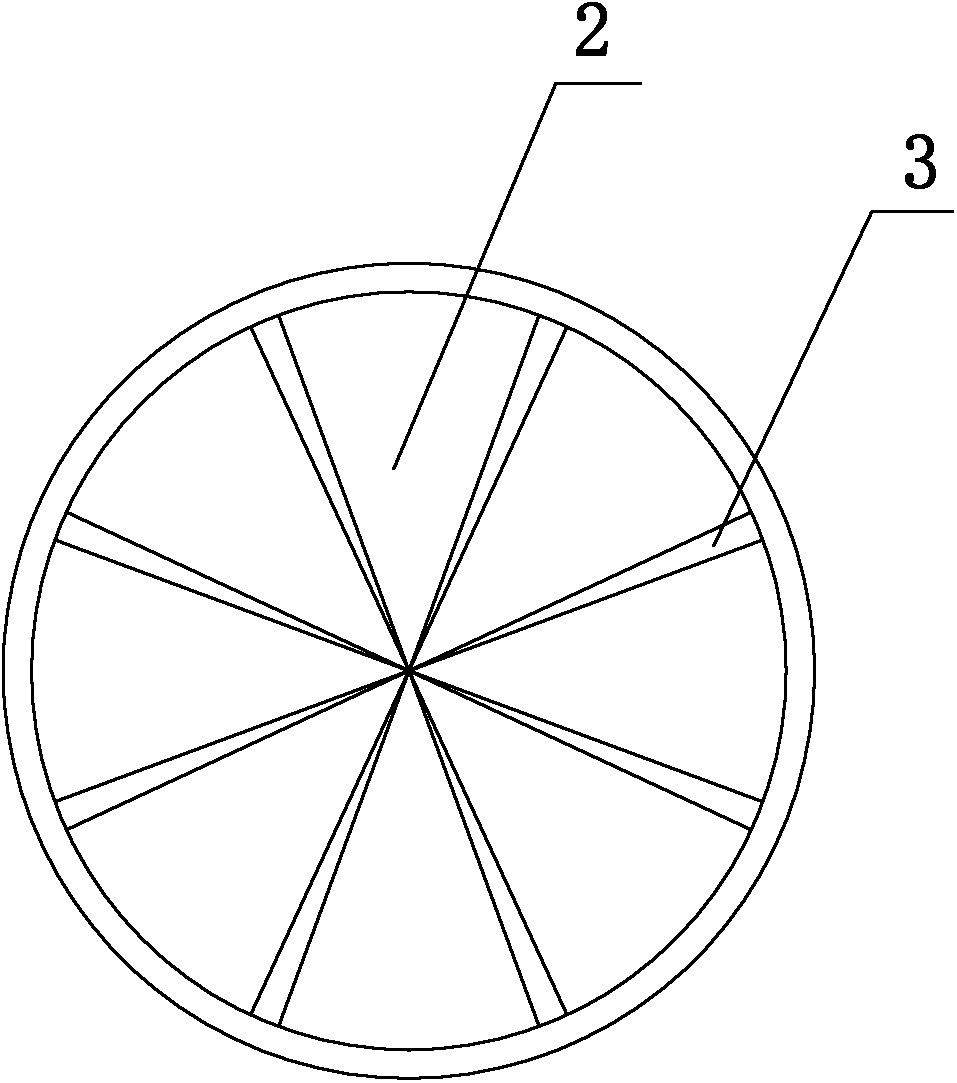

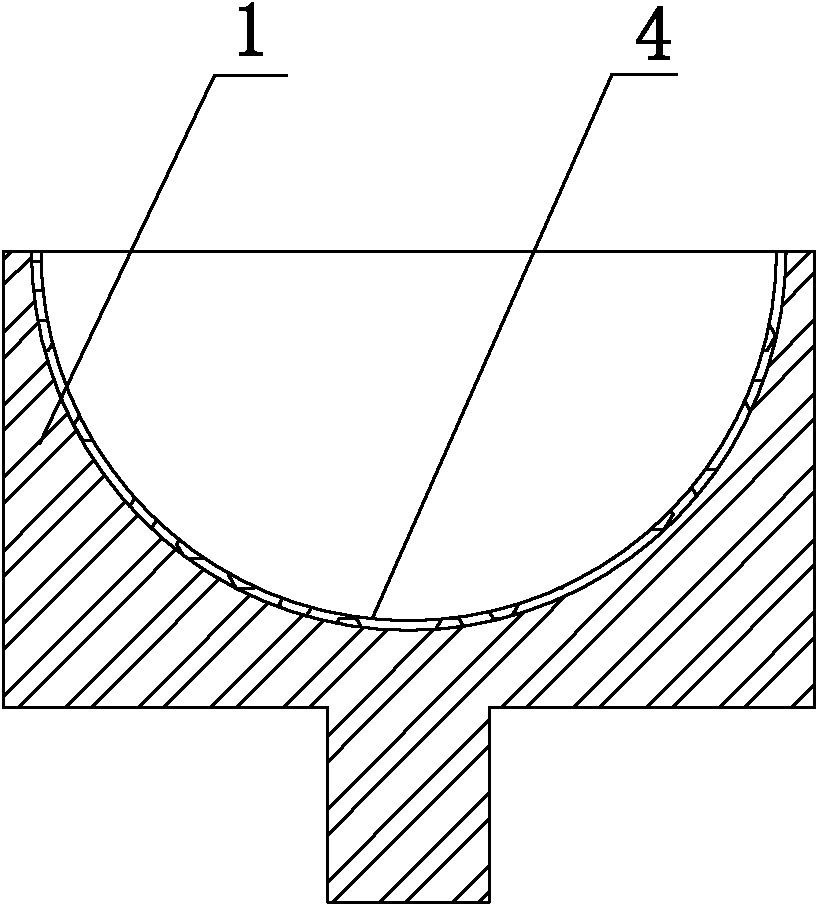

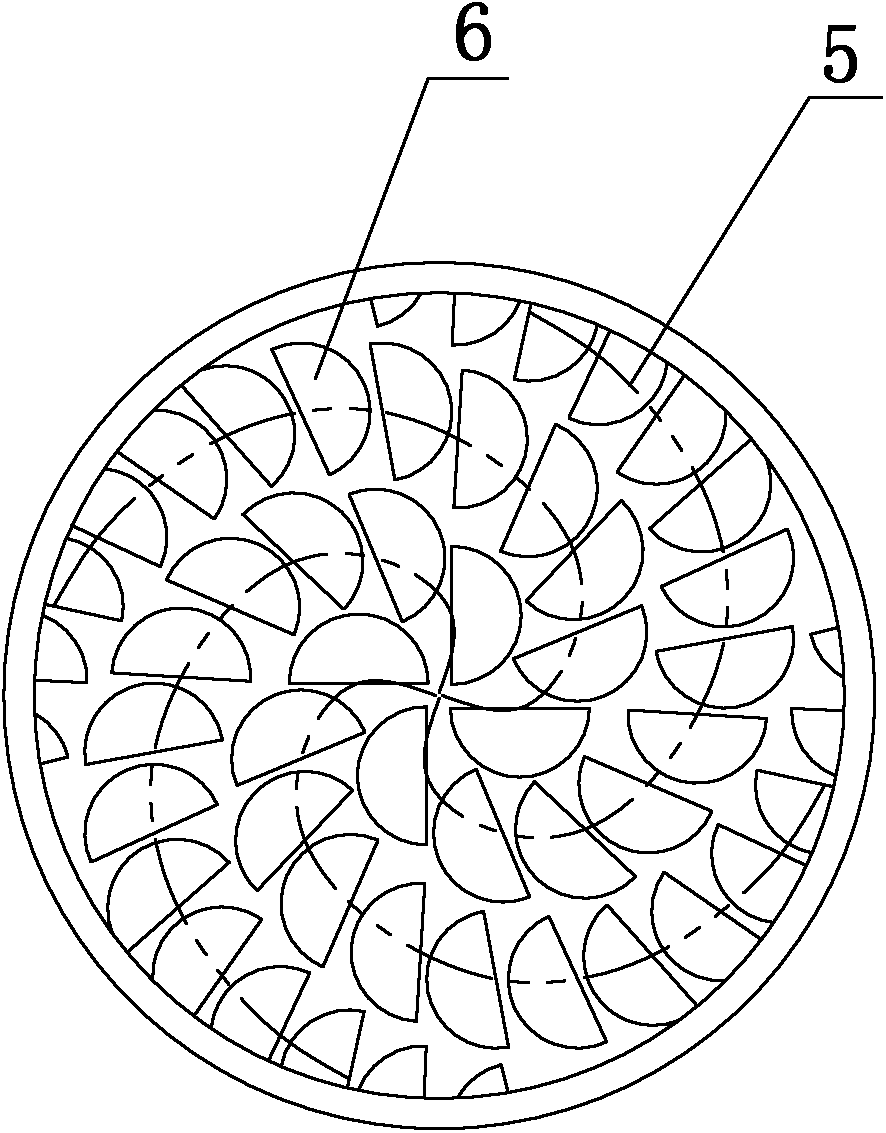

[0018] Such as image 3 and Figure 4 As shown, the present invention cuts the polyurethane sheet into small circles or small semicircles 6, wherein the radius of the small circles or small semicircles 6 is between 1mm and 10mm, and these small circles or small semicircles 6 are arranged according to the multi-head spiral The way of line 5 is pasted on the polishing base mold 1. If the small semicircle 6 is used, the direction of the cut surface of the small semicircle 6 always points to the axis of the polishing base mold 1, so that the polishing mold conforms to "cosine wear", image 3 Shown is the small half-circle 6 . Among them, the multi-headed spiral line refers to: two or more mutually symmetrical points do spiral motion along the spherical surface, and the axial displacement of the point is proportional to the corresponding angular displacement.

[0019] Above-mentioned small disc or small semicircle 6 can also be pasted on the polishing matrix 1 according to the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com