Method for extracting antitumor component caffeic acid from Elsholtzia splendens

A caffeic acid and anti-tumor technology, which is applied in the field of biological resource utilization of natural products, can solve the problems such as the separation and purification of active ingredient caffeic acid that has not been reported, and achieve the effects of simple and safe extraction process, high yield and simple extraction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

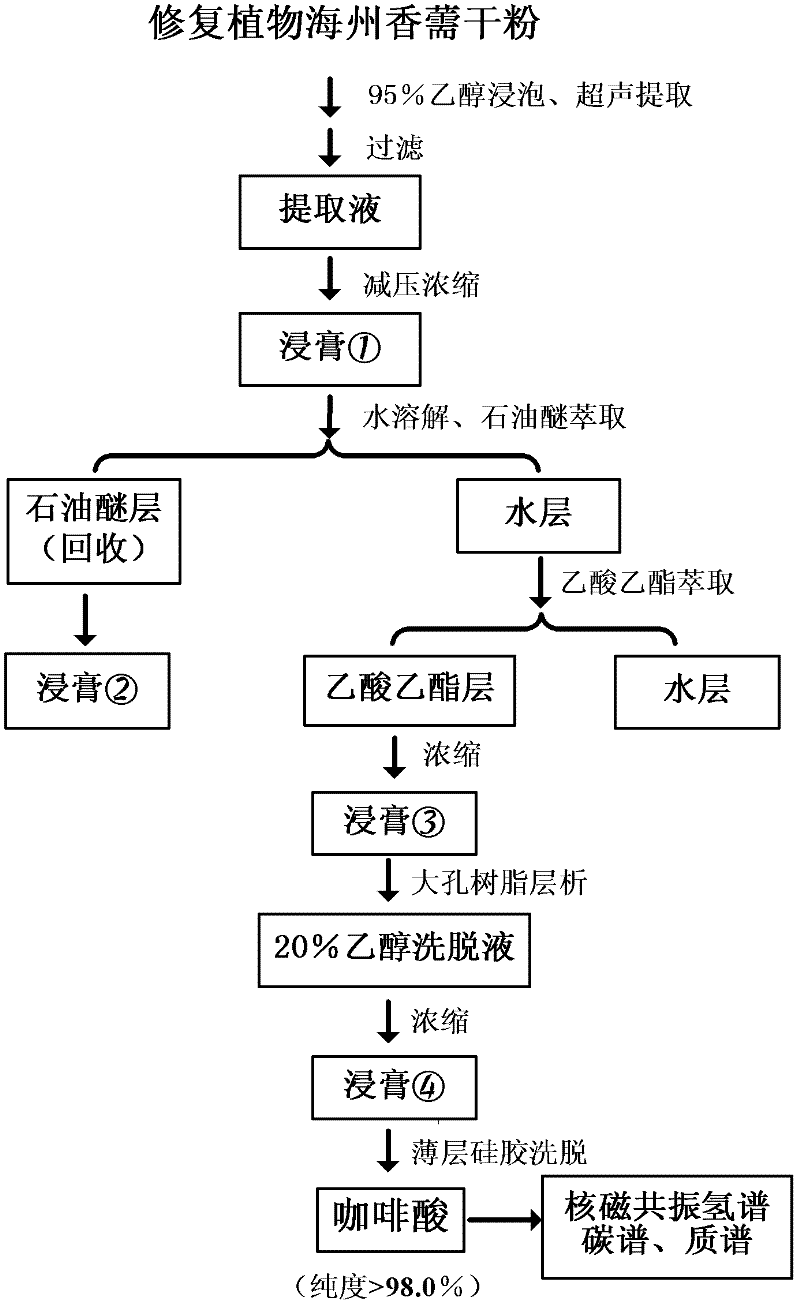

[0037] Embodiment 1: A method for extracting caffeic acid, an anti-tumor component in Herba Cinnamomi, followed by the following steps:

[0038] 1), rough extraction:

[0039] Grind into dry powder (moisture content is lower than 0.5%, weight ratio) after air-drying the flower branches and leaves of Herba Cinnamomi harvested in the full bloom stage, pass through a 100 mesh sieve, take the above 500g dry powder, place it in a 10L plastic bucket, add 95 % (V / V) ethanol 5L, stirred evenly and soaked for 3 days until the material was completely imbibed, treated with 40KHz ultrasonic frequency for 1 hour, and suction filtered to obtain the filtrate.

[0040] Repeat the above-mentioned process for a total of 3 times with the residue obtained by suction filtration (that is, replace the dry powder with the residue, and repeat the above-mentioned leaching).

[0041] Combine the filtrate obtained from 4 extractions; then concentrate in vacuo at 45°C to obtain 126.1 g of dilute extract ...

Embodiment 2

[0065] Embodiment 2: A method for extracting caffeic acid, an anti-tumor component in Rhizoma pilosula, followed by the following steps:

[0066] 1), rough extraction:

[0067] Air-dry the flowering branches and leaves of Rhizoma haizhou harvested at the full bloom stage and grind them into dry powder, pass through a 100-mesh sieve, take the above 5000g dry powder, put it in a 100L plastic bucket, add 75L of 95% (V / V) ethanol, and stir well Soak for 4 days until the material is completely imbibed, treat with an ultrasonic frequency of 40KHz for 1 hour, and filter with suction to obtain a filtrate.

[0068] Repeat the above-mentioned process for a total of 3 times with the residue obtained by suction filtration (that is, replace the dry powder with the residue, and repeat the above-mentioned leaching).

[0069] Combine the filtrate obtained from 4 extractions; then concentrate in vacuo at 45°C to obtain 1275.1g of dilute extract ①. Yield 25.50%.

[0070] 2), extraction:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com