Method for preparing asphalt concrete anti-rutting agent for road by in-situ graft modification

A technology of road asphalt and anti-rutting agent, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of high price and limited output of anti-rutting agent, improve anti-rutting performance, reduce production cost, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

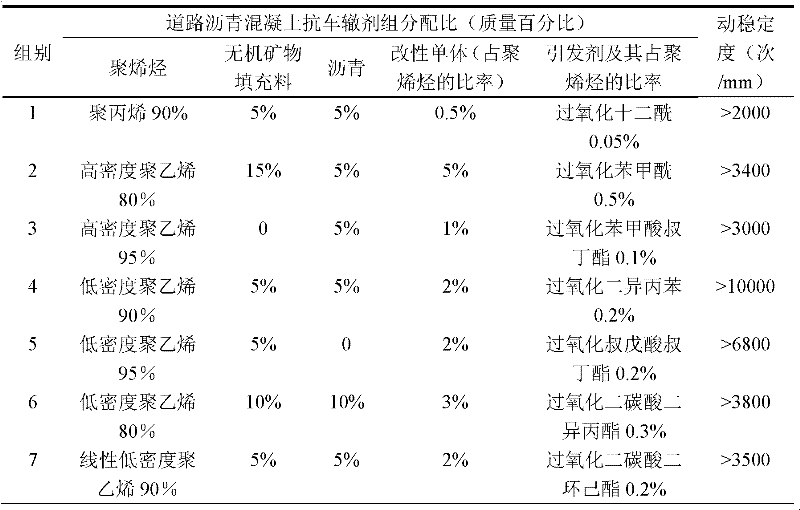

Embodiment 1

[0035] The mass percentage is 90% polypropylene, 5% micron calcium carbonate, 5% rock pitch, and the mass fraction is polypropylene 0.5% glycidyl methacrylate and 0.05% initiator lauryl peroxide, Mix uniformly at 25°C and 1 atm, put the mixture into a single-screw extruder, melt and extrude at 190-220°C barrel temperature, 30rpm screw speed, granulate, and dry to obtain 2-6mm long The in-situ graft modified road asphalt concrete anti-rutting agent prepared by the inventive method. According to the "Asphalt Mixture Specimen Preparation Method" (T0719-1993) standard in the "Asphalt and Asphalt Mixture Test Regulations for Highway Engineering" (JTJ 052-2000), the dynamic stability of the prepared asphalt mixture specimen is greater than 2000 times / mm, the dynamic stability of road asphalt concrete without adding road asphalt concrete anti-rutting agent has increased by 25%.

Embodiment 2

[0037] The mass percentage is 80% high-density polyethylene, 15% nano-calcium carbonate, 5% lake asphalt, and the mass fraction is maleic anhydride of high-density polyethylene 5% and 0.5% initiator benzoyl peroxide , uniformly mixed at 25°C and 1 atm, the mixture was added to a twin-screw extruder, melted and extruded at a cylinder temperature of 190-220°C and a screw speed of 100rpm, granulated, and dried to obtain 2-6mm long The in-situ graft modified road asphalt concrete anti-rutting agent prepared by the method of the invention. According to the "Asphalt Mixture Specimen Preparation Method" (T0719-1993) standard in the "Asphalt and Asphalt Mixture Test Regulations for Highway Engineering" (JTJ 052-2000), the dynamic stability of the prepared asphalt mixture specimen is greater than 3400 times / mm, which is 112.5% higher than the dynamic stability of road asphalt concrete without adding road asphalt concrete anti-rutting agent.

Embodiment 3

[0039] The mass percentage is 95% high-density polyethylene, 5% rock asphalt, and the mass fraction is maleic anhydride of 1% high-density polyethylene and 0.1% initiator tert-butyl peroxybenzoate, at 25 ℃, Uniform mixing under 1atm environment, the mixture is added to a twin-screw extruder, melt-extruded, granulated, and dried at a cylinder temperature of 190-220°C and a screw speed of 50rpm to obtain a 2-6mm length prepared by the method of the present invention. In-situ graft modified road asphalt concrete anti-rutting agent. According to the "Asphalt Mixture Specimen Preparation Method" (T0719-1993) standard in the "Asphalt and Asphalt Mixture Test Regulations for Highway Engineering" (JTJ 052-2000), the dynamic stability of the prepared asphalt mixture specimen is greater than 3000 times / mm, which is 87.5% higher than the dynamic stability of road asphalt concrete without adding road asphalt concrete anti-rutting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com