Automatic production equipment and process for finishing after bast fiber degumming

A bast fiber and production equipment technology, applied in the field of bast fiber degumming and finishing automatic production equipment, can solve the problems of high pollution and high water consumption, and achieve the effects of high mechanization, improved reliability and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

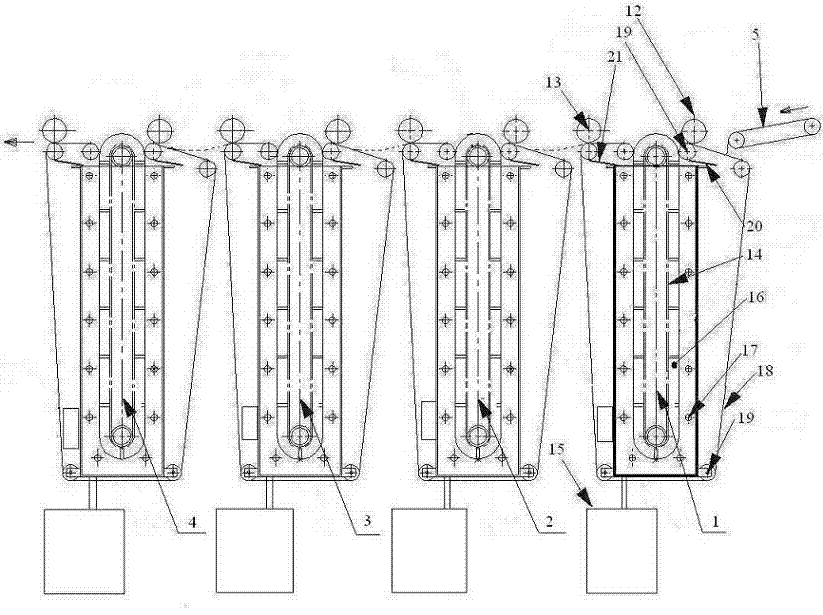

[0024] Such as figure 1 The shown automatic production equipment for bast fiber degumming and finishing is composed of four sets of multifunctional special equipment with the same structure connected in series, which are respectively washing fiber opening machine 1, bleaching machine 2, bleaching machine 3 and oil booster Rouji 4, for simplicity, in figure 1 Only the parts of the washing fiber opening machine 1 are marked, and the reference signs of the other three equipment are the same as the washing fiber opening machine 1, so they are omitted; the four equipments are mainly composed of the body, and are respectively arranged at the inlet and outlet of the body. The front dehydration drum 12 at the end and the rear dehydration drum 13, the conveying curtain 18 arranged on the body, and the inner mesh cloth 14 arranged in the body constitute; the washing chamber 16 is formed between the inner mesh cloth 14 and the conveying curtain 18; The inside of the body is provided wit...

Embodiment 2

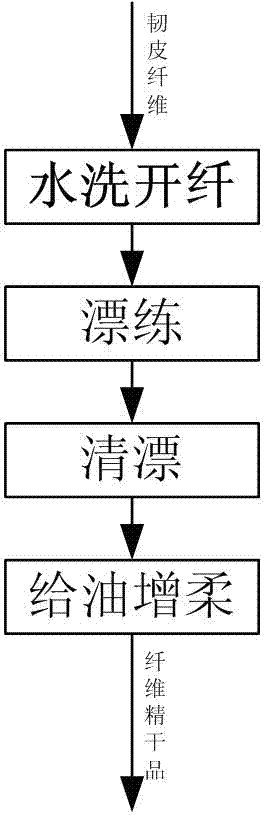

[0033] The automated production equipment for bast fiber degumming and finishing in this embodiment is the same as in Example 1, the automated production process for bast fiber degumming and finishing, including the following steps:

[0034] (a) The flax bast fiber after chemical scouring and biological degumming treatment is fed into the washing fiber opening machine 1 through the feeding conveyor belt 5, and after being rolled by the front dehydration drum 12 of the water washing fiber opening machine 1 to remove the residual liquid, it is The conveying curtain 18 and the inner mesh cloth 14 are clamped and sent into the washing chamber 16, and are washed by the cross-impact cleaning of the spray device 17 of the water-washing opener 1, the internal and external high-pressure water columns, to fully remove pectin and sundries, decompose the fibers, and wash them open. The rear dehydration drum 13 of the fiber machine 1 grinds and removes part of the cleaning water; the excess...

Embodiment 3

[0040] The automated production equipment for bast fiber degumming and finishing in this embodiment is the same as in Example 1, the automated production process for bast fiber degumming and finishing, including the following steps:

[0041] (a) The hemp bast fiber after chemical scouring and biological degumming treatment is fed into the washing fiber opening machine 1 through the feeding conveyor belt 5, and after being rolled by the front dehydration drum 12 of the water washing fiber opening machine 1 to remove the residual liquid, it is The conveying curtain 18 and the inner mesh cloth 14 are clamped and sent into the washing chamber 16, and are washed by the cross-impact cleaning of the spray device 17 of the water-washing opener 1, the internal and external high-pressure water columns, to fully remove pectin and sundries, decompose the fibers, and wash them open. The rear dehydration drum 13 of the fiber machine 1 grinds and removes part of the cleaning water; the excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com