A water level measuring device and using method of a small/micro buoyancy washing machine

A water level measurement and micro-buoyancy technology, which is applied to the control device, washing device, and other washing machines of washing machines, etc., can solve the problem that small/micro-buoyancy washing machines cannot be directly applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

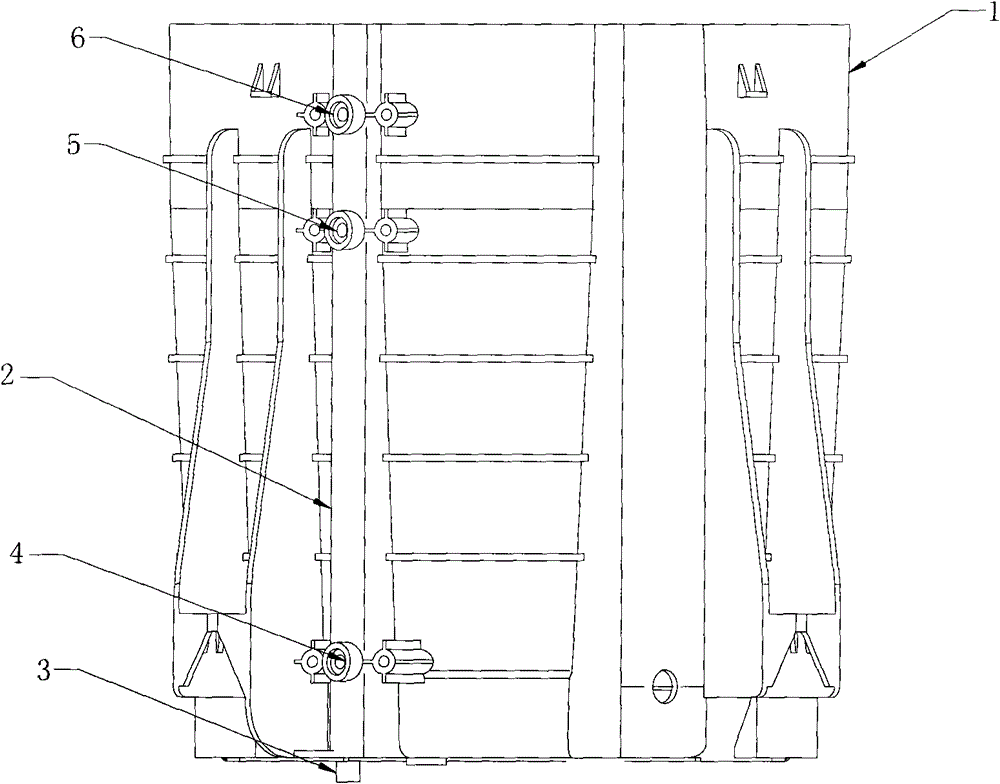

[0022] Such as figure 1 , 2 As shown, the three measurement ends and the common end 3 of this solution are installed on the same fixed plate 2, and the fixed plate is an L-shaped structure, wherein the long folded edge is installed on the outer surface of the outer tub 1 of the washing machine, and the short folded edge is installed on the outer surface of the washing machine outer tub 1. At the bottom of the outer barrel, the measuring end is installed on the long fold, and the common end is installed on the short fold. There are three measurement terminals, namely the drainage measurement terminal 4 installed at the bottom of the outer tub, the washing measurement terminal 5 installed at the bottom 4 / 5 upwards, and the overflow measurement terminal 6 installed at the top of the outer tub 20MM downwards. In order to prevent excessive washing water, the installation position needs to consider the influence of the rotation of the water flow during washing. The number of measu...

Embodiment 2

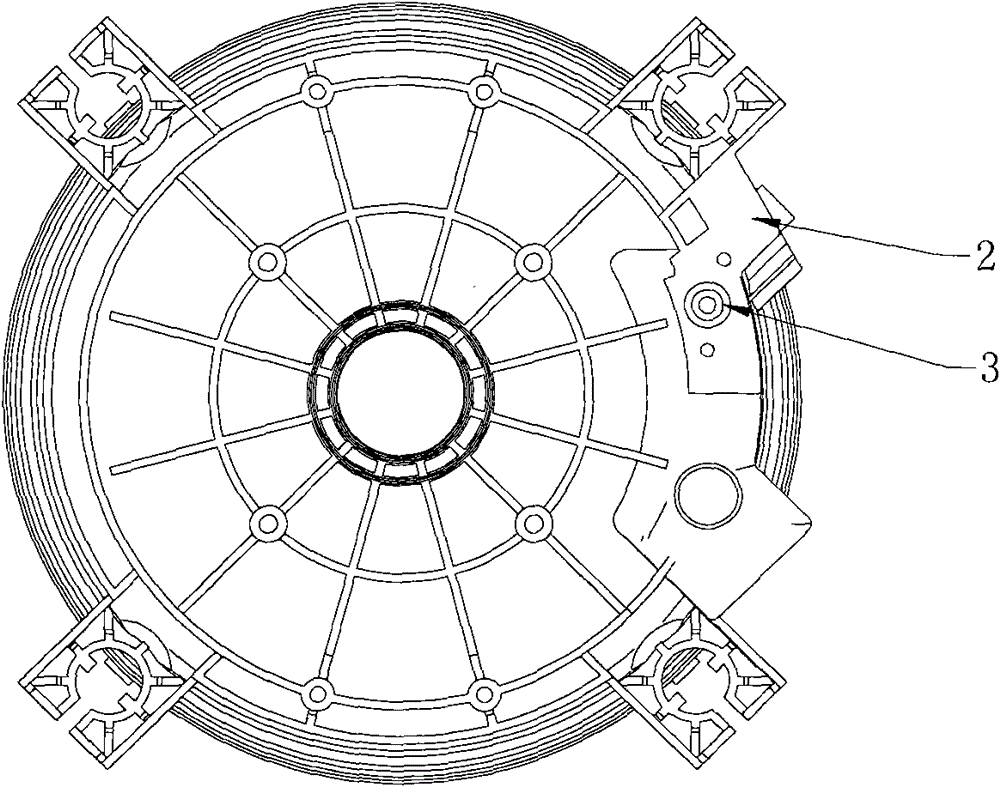

[0024] On the basis of Embodiment 1, the measuring end is installed in the fixed plate, and the fixed plate is formed by buckling and sealing two plates, and a slot parallel to the axis of the outer barrel is set on the inner wall of the outer barrel, and the fixed plate is inserted into the slot Inside, the fixed plate is located in the outer tub, and three through holes are set on the plate to expose the measuring point end of the measuring end. The wires of the three measuring ends are drawn from one end of the fixing plate to connect with the main control unit of the washing machine. Make a preventive seal between them to avoid water entering the fixed plate. This solution does not use destructive installation on the outer barrel, but only sets a concave or convex slot, which greatly reduces the volume, and is easier to maintain, and it is more convenient to seal the separate fixing plate.

[0025] The using method process of the present invention is as follows:

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com