Self-heating floor system and self-heating floor thereof

A self-heating, floor technology, applied in the field of building decoration, can solve problems such as hidden dangers, hidden dangers of safety, affecting heating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] (Example 1, self-heating floor)

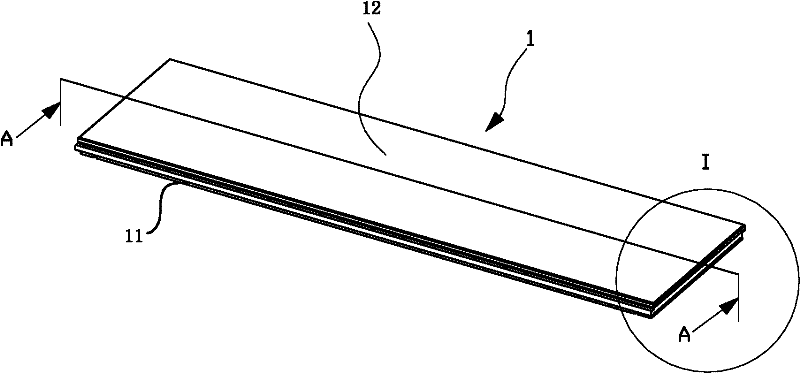

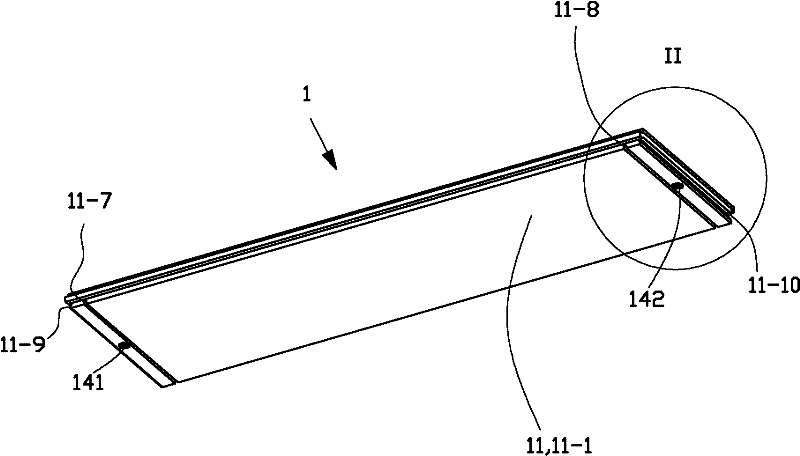

[0105] See Figure 1 to Figure 4 , Figure 8 and Figure 9 , The self-heating floor 1 of this embodiment includes a lower body 11 , an upper panel 12 , a heating sheet 13 and a plug assembly 14 .

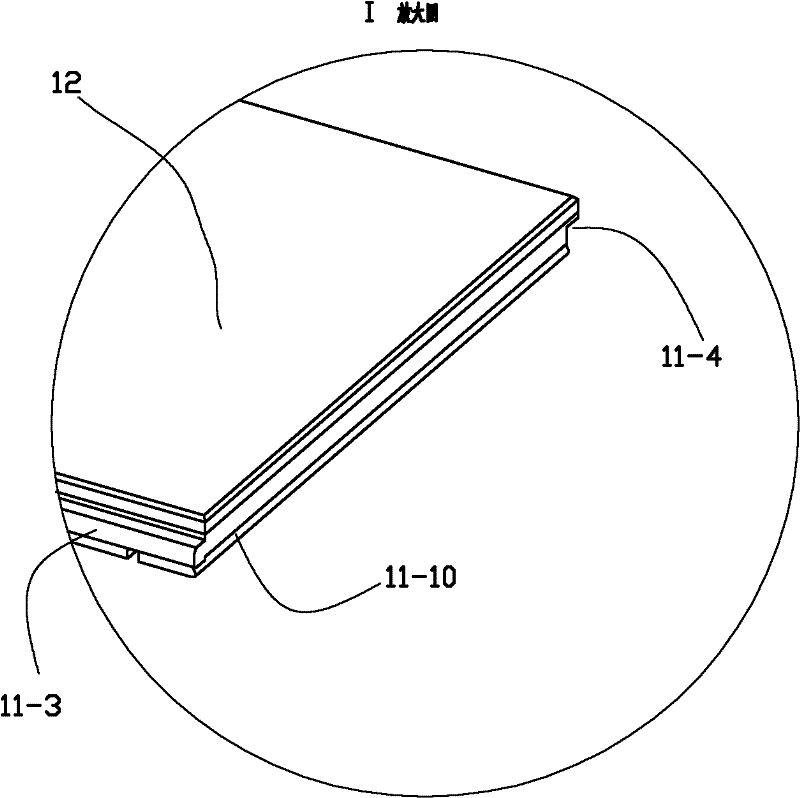

[0106] See figure 2 , Figure 4 and Figure 5 , the lower main body 11 is a homogeneous piece of wood, including a main body 11-1 with a basic shape of a cuboid, a tenon 11-3 located on the front side of the main body 11-1 and a tenon located on the rear side of the main body 11-1. The socket slot 11-4 and the socket tenon 11-3 are the parts that connect and cooperate with the socket slots of the self-heating floor adjacent to the front side during use, and the socket slot 11-4 is adjacent to the rear side during use. The parts where the joints of the self-heating floor are connected with each other.

[0107] See Figure 5 and Figure 9 , The lower main body 11 is also provided with an upper groove 11-2, 2 plug holes, 2 blocking and...

Embodiment 2

[0115] (Example 2, self-heating floor system)

[0116] See Figure 11 and Figure 12 , when describing the self-heating floor system in this embodiment, its front and rear, left and right, and up and down directions are the same as those described in Embodiment 1, that is, with Figure 11 The length direction of the mounting base 2 is the front-to-back direction, that is, Figure 12 The lower left in the middle is the front side, the upper right is the rear side, and the Figure 11 The up, down, left, and right directions of are the described up, down, left, and right directions.

[0117] See Figure 26 and Figure 27 , The self-heating floor system of this embodiment includes a self-heating floor, a mounting seat 2, a plugging blocking member 31, a plugging strip 32 and a power supply system. The power supply system includes a power supply line 600 and a keel line 400 . The self-heating floor adopts the self-heating floor 1 of Embodiment 1.

[0118] See Figure 11 , ...

Embodiment 3)

[0151] The rest of this embodiment is the same as Embodiment 1, the difference is that the self-heating floor 1 is also provided with a third plug assembly 14, and the plug assembly 14 is arranged at a position vertically arranged along the width direction of the self-heating floor 1 A quarter of the length of the self-heating floor 1 is at a symmetrical position on the plane, and the electric heater 13 of the self-heating floor 1 is provided with a corresponding electrode, and the corresponding position of the lower body 11 is provided with a corresponding electrode of the electric heater 13 groove. When in use, this self-heating floor 1 can be cut accordingly, and used in the corner of the room to be laid in the nail-free clip-on self-heating floor system in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com