High-brightness excitation method and light emitting device based on optical wavelength conversion

一种光波长转换、发光装置的技术,应用在光源领域,能够解决效率降低、成本高、光能损耗严重等问题,达到提高光功率密度、解决散热问题、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

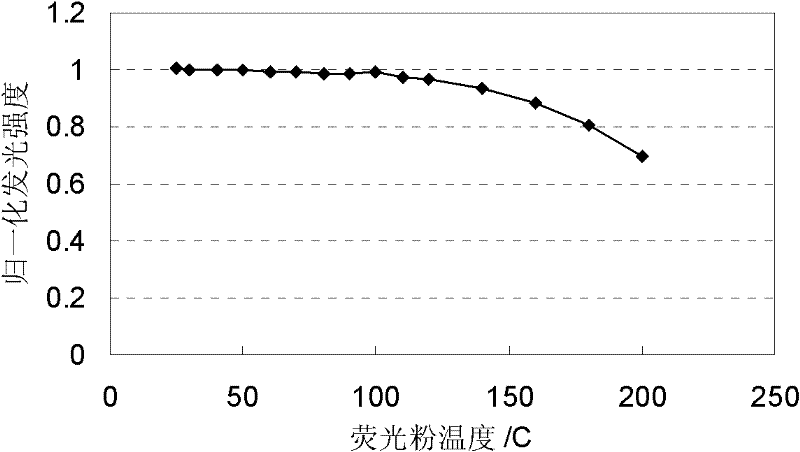

[0077] The general idea of the technical scheme of the present invention is: compared with the prior art, only the excitation light is provided from one side of the phosphor powder, and the excited light is extracted from the other side of the phosphor powder; the present invention simultaneously excites the phosphor powder from both sides To increase the optical power density of the excitation light, that is, the optical power per unit area; at the same time, the problem of heat dissipation of the phosphor can be solved by measures such as a transparent heat-conducting substrate.

[0078] The technical solution for realizing the purpose of the invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

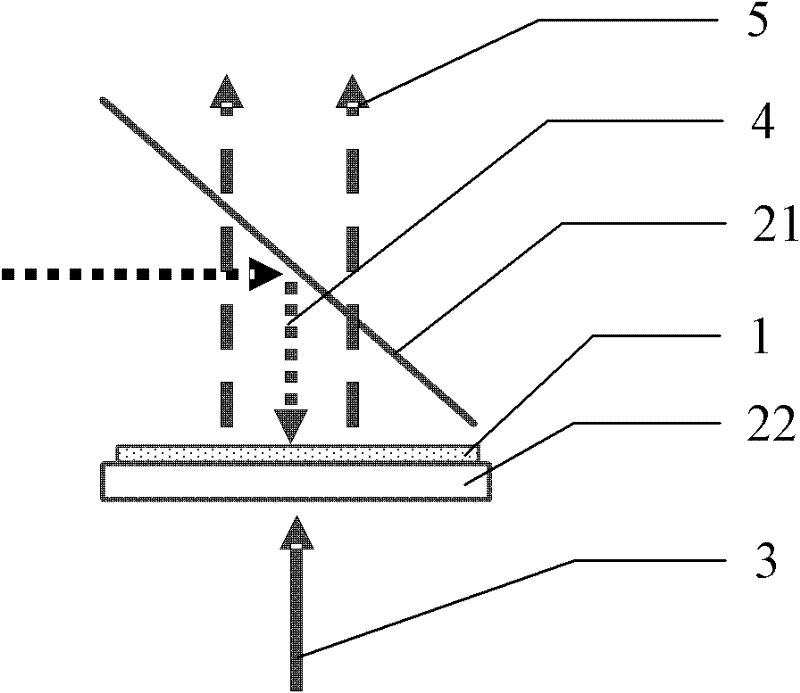

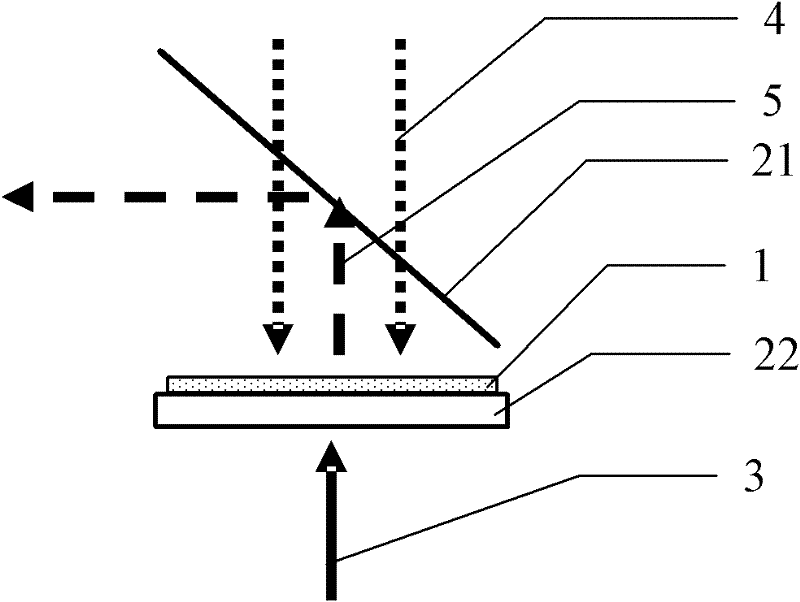

[0079] Please refer to figure 2 , a light-emitting device based on light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com