Spring piece for sensor

A technology of spring leaf and sensor, applied in the field of spring leaf, to achieve the effect of reasonable design, small linear error and easy calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

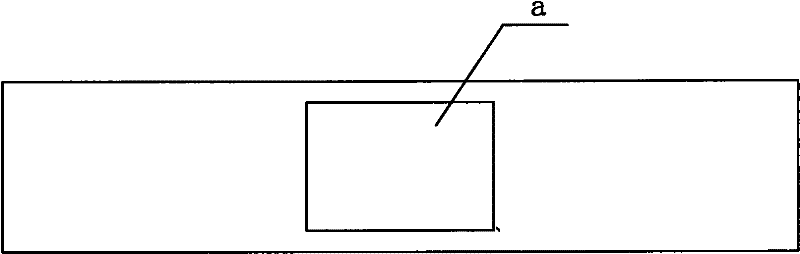

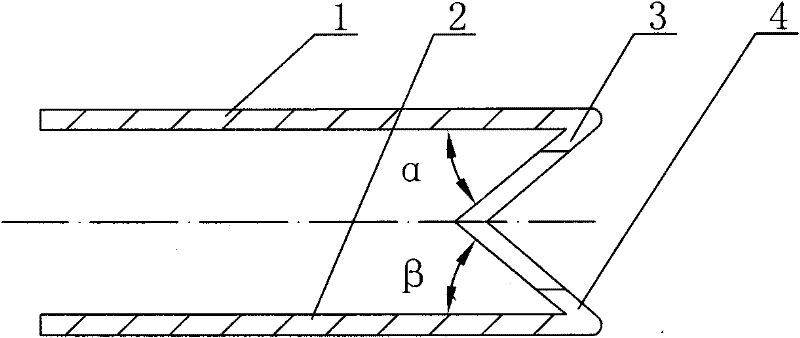

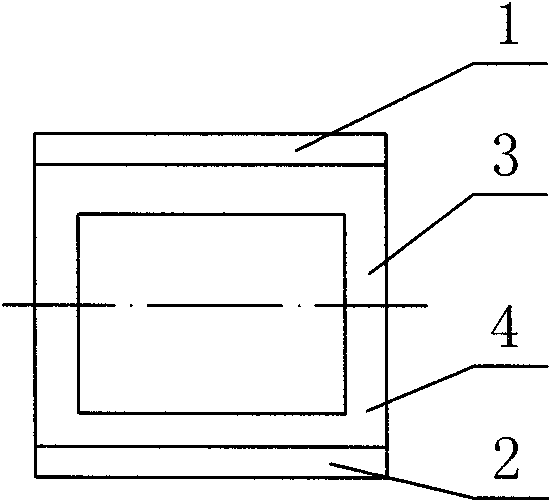

[0019] exist figure 1 , 2 , 3, 4, the spring sheet of the sensor in this embodiment is formed by bending a rectangular spring sheet with a rectangular through hole a processed in the middle, the thickness of the spring sheet is 0.4mm, and the rectangular spring sheet is bent to form an upper flat plate 1. The W-shaped structure formed by the lower plate 2 and the folded plate connecting the end of the upper plate 1 and the end of the lower plate 2 as a whole, the upper plate 1 and the lower plate 2 are parallel to each other. The folded plate of this embodiment is composed of an upper plane plate 3 and a lower plane plate 4. The angle α between the upper plane plate 3 and the upper plate 1 is 45°, and the lower plane plate 4 and the lower plane plate The angle β between 2 is 45°. Half of the rectangular through hole a is located on the upper plane plate 3 and the other half is located on the lower plane plate 4 . The rectangular through hole a is symmetrical to the intersect...

Embodiment 2

[0021] In the embodiment, the angle α between the upper plane plate 3 and the upper plate 1 is 20°, the angle β between the lower plane plate 4 and the lower plate 2 is 20°, and the rectangular through hole a is on the upper side The positions of the plane plate 3 and the lower plane plate 4 are the same as in the first embodiment. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0023] In the embodiment, the angle α between the upper plane plate 3 and the upper plate 1 is 70°, the angle β between the lower plane plate 4 and the lower plate 2 is 70°, and the rectangular through hole a is on the upper side The positions of the plane plate 3 and the lower plane plate 4 are the same as in the first embodiment. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com