Assessment method for rolling bearing performance variation

A rolling bearing and performance technology, applied in the field of failure analysis and monitoring of rolling bearing performance, can solve problems such as rolling bearing performance variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

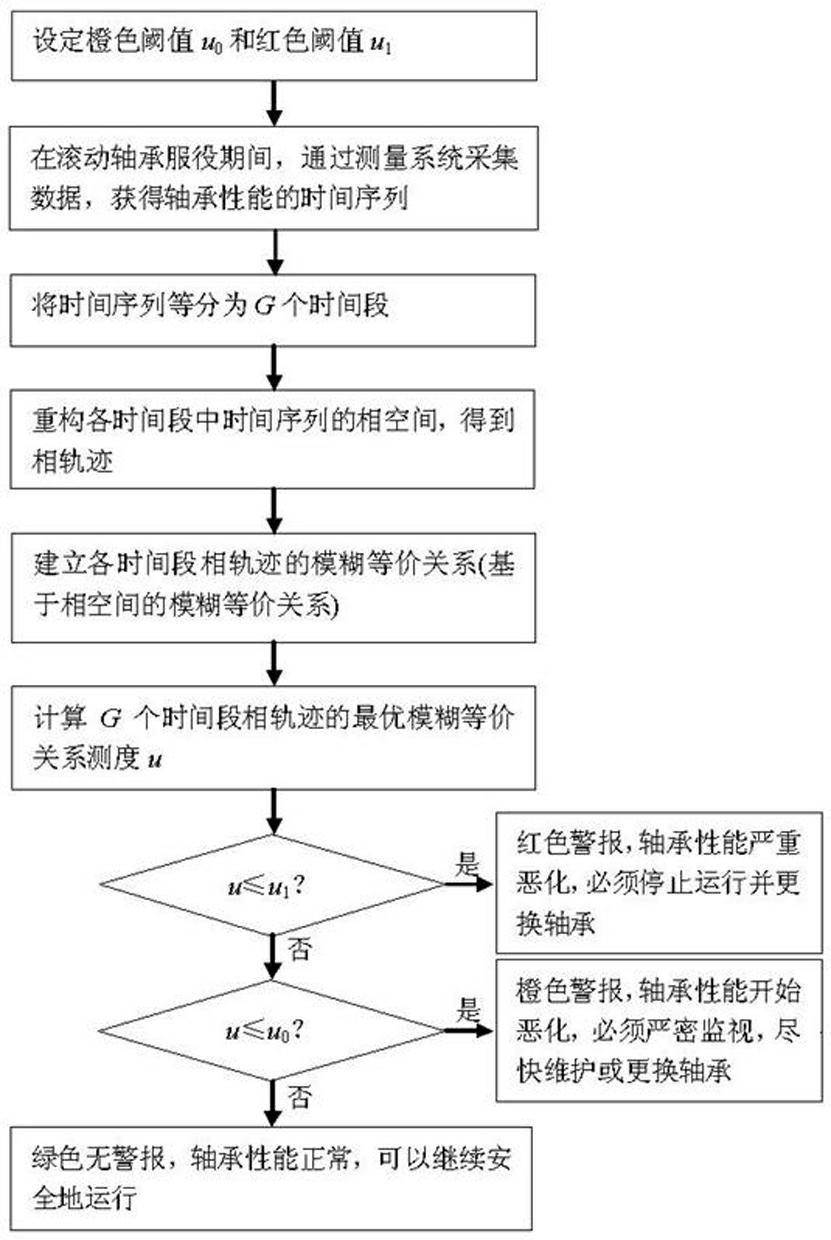

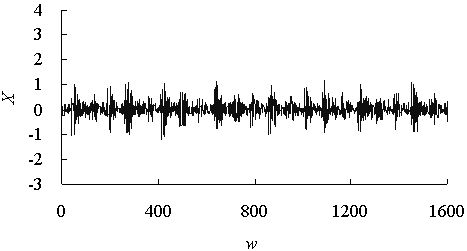

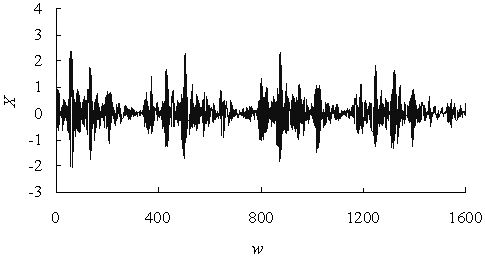

[0149] Example 1: figure 2 , 3 , 4 are part of the time series data of the bearing vibration when the grooves of the inner ring of the rolling bearing in a certain system have wear scar diameters of 0.1778, 0.5334 and 0.7112mm respectively. It can be seen that the larger the diameter of the wear scar, the more severe the vibration of the bearing. Therefore, the wear condition of the internal parts of the bearing can be deduced by analyzing the changes of the vibration information characteristics.

[0150] For the convenience of description, in this embodiment 1, the orange threshold is set u 0 =0.705, red threshold u 1 =0.555. Through this embodiment 1, the specific operation steps and calculation process of the present invention will also be described.

[0151] 1 Obtaining time series of rolling bearing performance

[0152] During the service period of the rolling bearing, the bearing inner ring channel in a certain system wears, and the diameter of the wear scar i...

Embodiment 2

[0165] Example 2 : Similar to Example 1, the optimal fuzzy equivalence relationship measure for other two wear scar diameters can also be calculated u , see Table 1 and Figure 5 , Figure 5 The dashed line part is a smooth extension of the solid line part.

[0166] Depend on Figure 5 The corresponding orange threshold can be obtained u 0 and the red threshold u 1 The wear scar diameters of d 0=0.15mm and d 1 =0.75mm.

[0167] from Figure 2~Figure 5 It can be seen that the wear scar diameter d and the optimal fuzzy relation measure u There is a nonlinear relationship between them, and the wear spot diameter d The larger the value, the optimal fuzzy equivalence relation measure u smaller. This means that as the wear degree of the internal parts of the bearing increases, the time series of the bearing vibration caused by the wear becomes less stable, and the fuzzy equivalence relationship between the phase trajectories in the phase space becomes less close. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com