General fixing device for probe of acoustic emission detection apparatus

A technology for acoustic emission detection and fixing devices, which is applied to measuring devices, measuring instrument components, and material analysis using sound waves/ultrasonic waves/infrasonic waves. The device has the advantages of simple structure, convenient operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

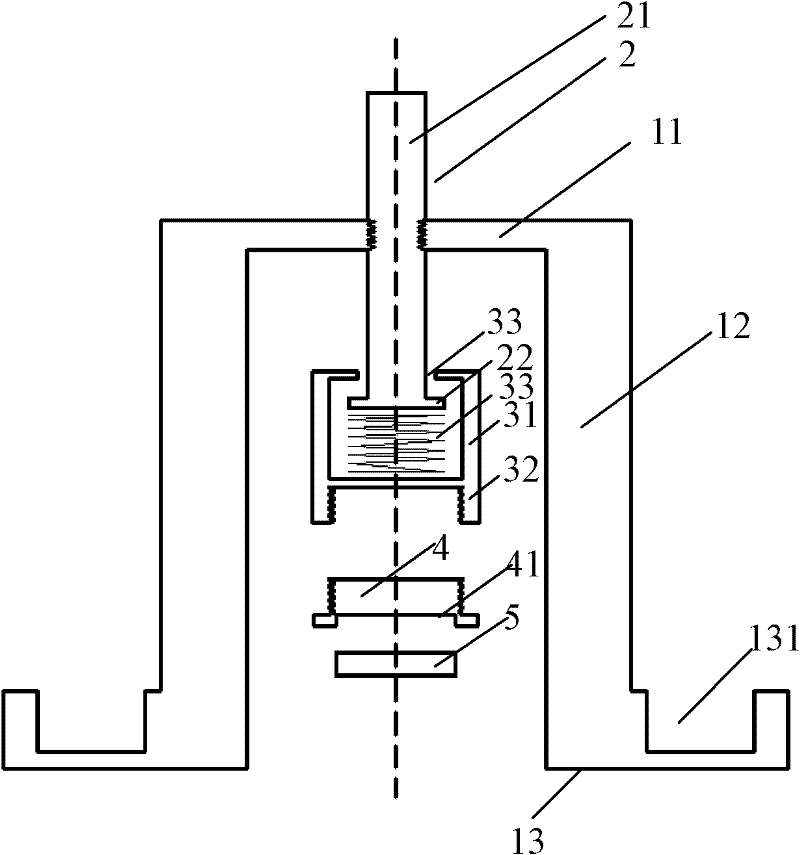

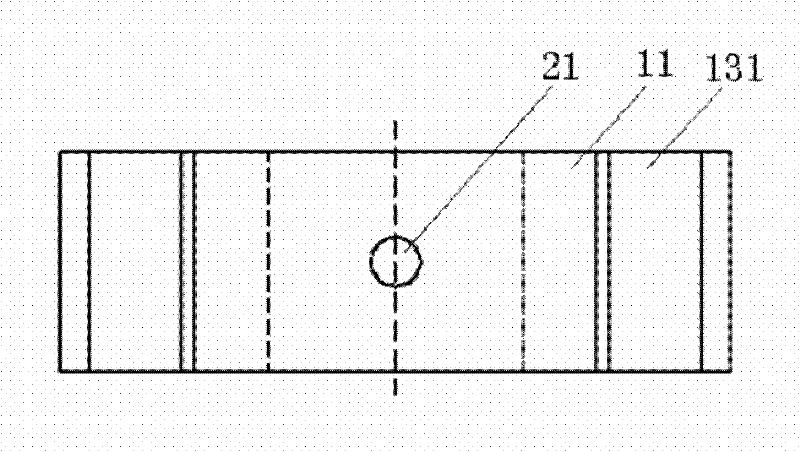

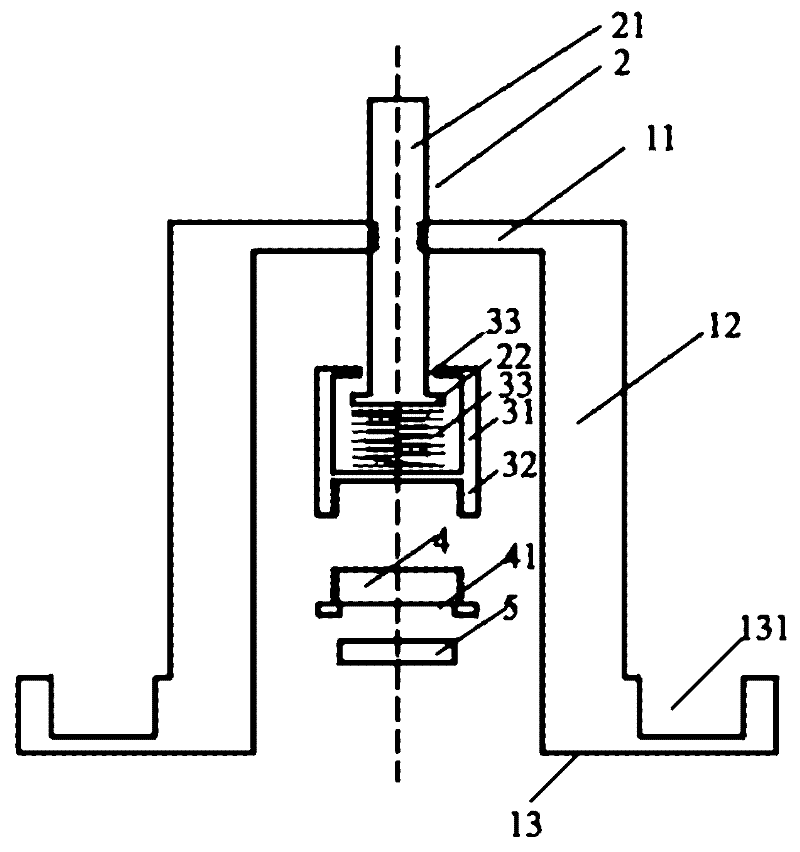

[0023] Attached Figure 1-2 The corresponding relationship between each reference number and the name of each component is: main body (1), height adjustment push rod (2), push rod pressure cap connector (3), replaceable probe pressure cap (4), probe ( 5) Cover (11), frame (12), bottom (13) of main body (1), hole (14), probe crimping surface (41), pressure sensitive sensor (42), push rod main body (21) ), the bottom end of the push rod (22), the upper cylinder connector (31), the lower connector (32), the spring (33), the opening (34), the groove (131);

[0024] in Figure 1-2 Among them, the universal fixing device includes a main body (1), a height adjustment push rod (2), a push rod pressure cap connector (3) and a replaceable probe pressure cap (4), wherein,

[0025] The main body (1) has a left-right symmetrical "ji"-shaped structure viewed from the front view direction, and the top of the "ji"-shaped structure is the cover (11) of the main body (1). The cover part (11) of (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com