LABview-based method for measuring temperature-resistivity

A measurement method and resistivity technology, applied in the field of temperature-resistivity measurement based on LABview, can solve the problems of cumbersome measurement steps, high measurement investment cost, long time consumption, etc., to save time and complexity, and to display results intuitively, The effect of saving labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

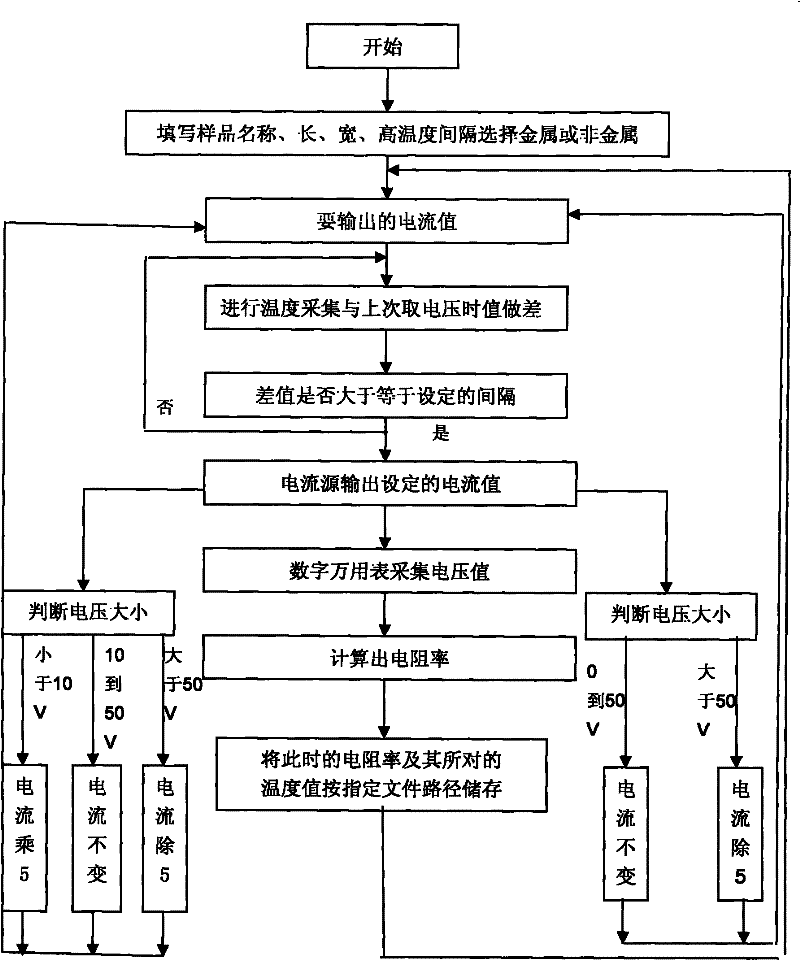

[0019] The specific steps of measuring the resistance material sample to be tested in this embodiment are as follows:

[0020] a. Weld the sample of resistance material to be tested to the sample holder. According to the four-terminal method, there are four terminals on the sample holder, which are current, voltage, voltage, and current terminals. At the same time, there is a thermocouple on the sample holder for collecting temperature values. , and then place the sample holder in the sample protection steel sleeve, and then put it in a container that uses water medium or liquid nitrogen to change the temperature;

[0021] b. Input the basic information of the resistance material sample to be tested on the measurement interface, including the name, length, width and height of the sample; select metal state or non-metal state; set the temperature interval of the sampling point, select the port channel of the instrument to set a After clicking start for the initial current value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com