Quick start method for power-supply system of CRDM (control rod drive mechanism)

A technology of drive mechanism and power system, applied in the direction of single-grid parallel feeding arrangement, etc., can solve the problems of high starting current, time-consuming, manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

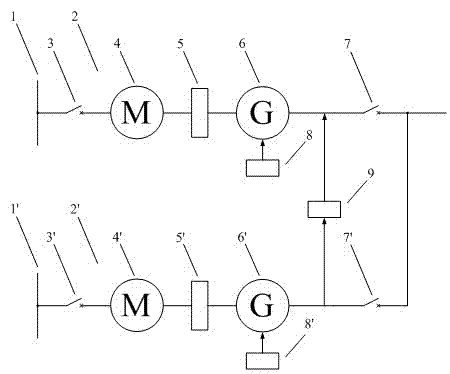

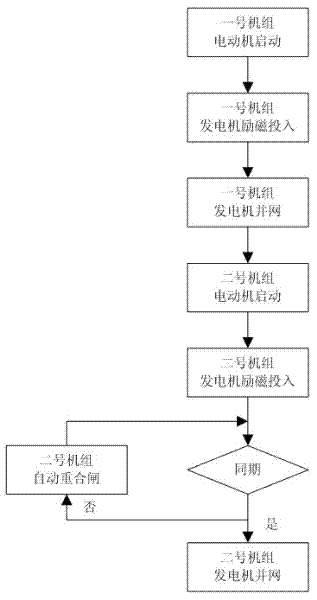

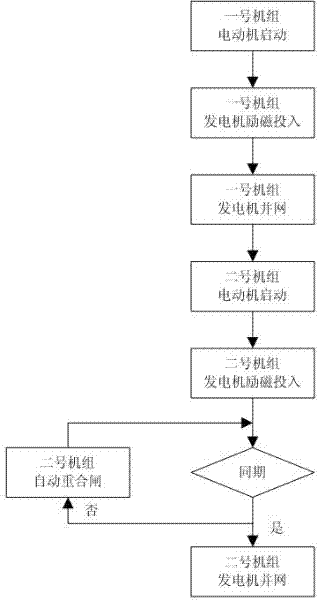

[0017] Such as figure 1 and figure 2 As shown, the present invention provides a method for quickly starting a control rod drive mechanism power supply system, the steps of which are:

[0018] Step 1. Start the motor of Unit 1

[0019] When the No. 1 unit 2 of the power system of the control rod drive mechanism is ready, the No. 1 unit input circuit breaker 3 is manually closed, and the motor 4 of the No. 1 unit is powered from the power bus 1 of the No. 1 unit. No. unit flywheel 5 drives No. 1 unit generator 6 to run.

[0020] Step 2. Generator excitation input of Unit 1

[0021] After the motor 4 of the No. 1 unit is running in the rated state, the automatic voltage regulator 8 of the No. 1 unit is automatically put into operation, the excitation current rises steadily from zero, the generator 6 of the No. 1 unit builds up the voltage steadily, and the machine terminal voltage rises steadily from zero. .

[0022] Step 3. Unit 1 generator connected to the grid

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com