Random winding of high voltage motor

A high-voltage electricity and winding technology, which is applied to electric components, manufacturing of motor generators, and the shape/style/structure of winding conductors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is specifically described below in conjunction with accompanying drawing;

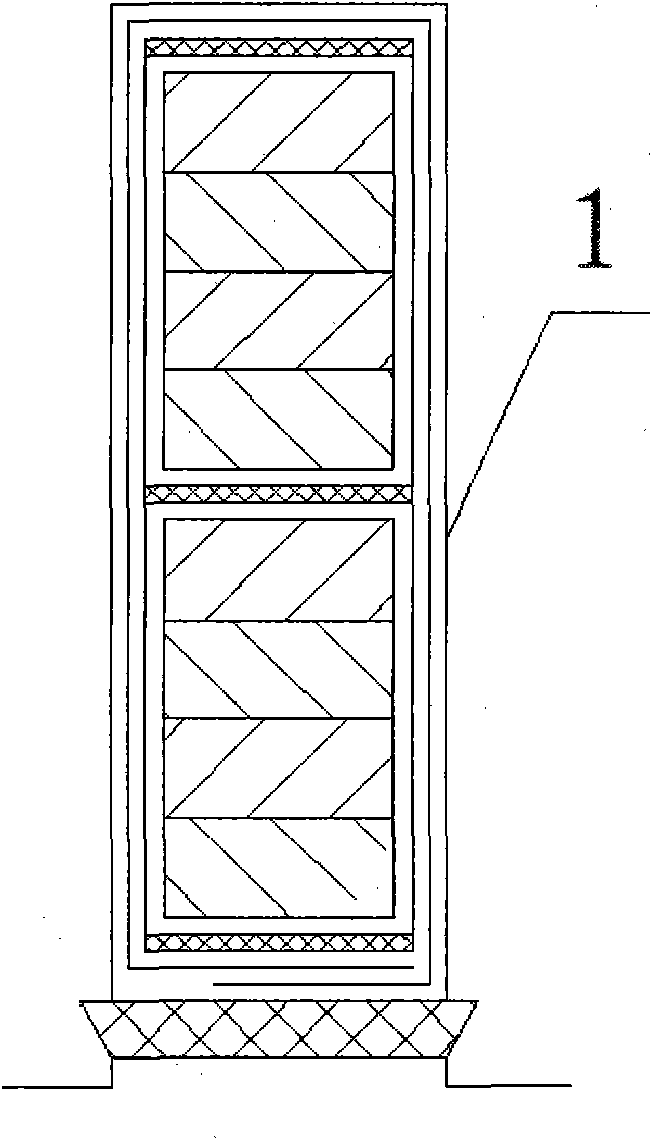

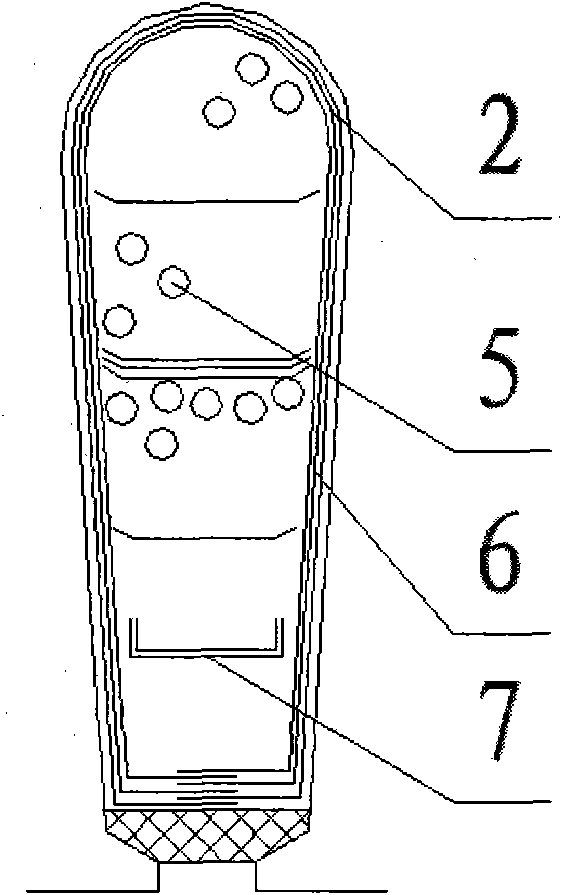

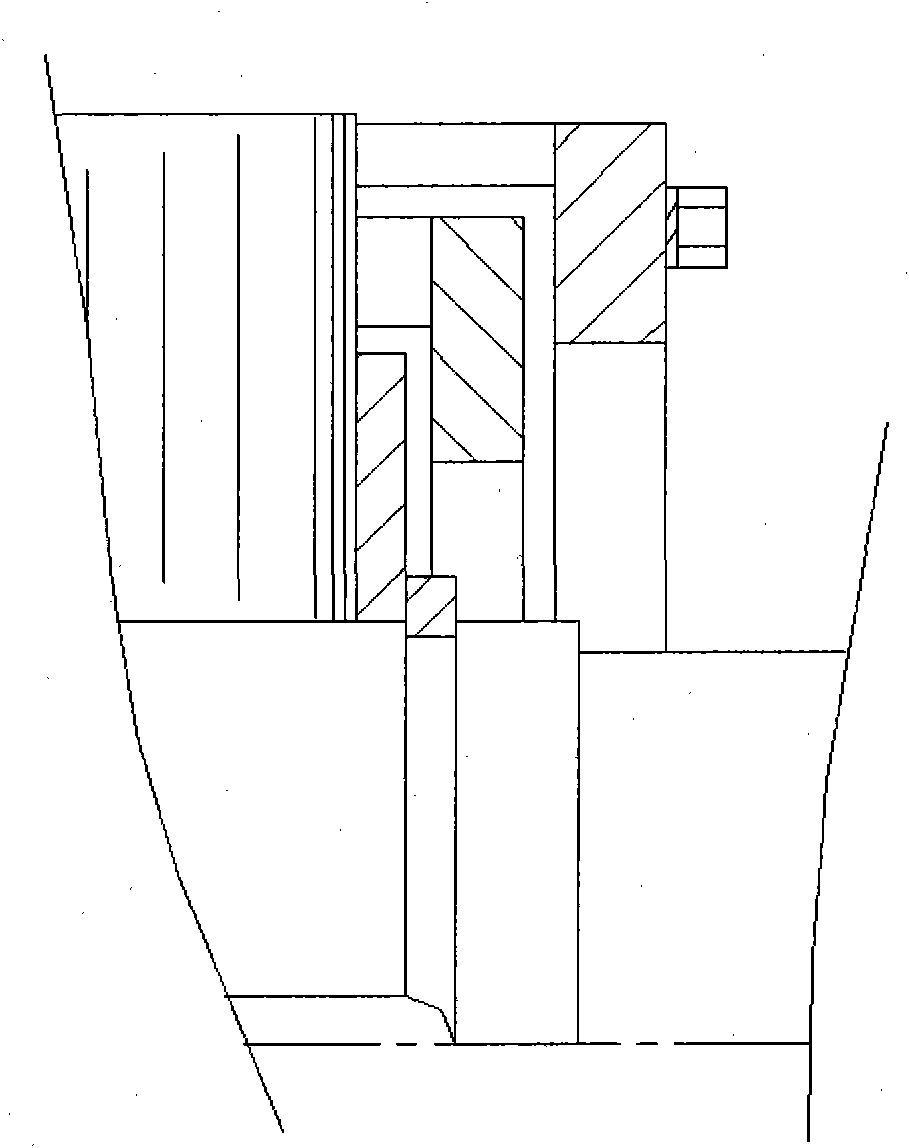

[0016] In terms of electromagnetic scheme design: on the one hand, we change the formed embedded wire winding into loose embedded wire winding embedded wire, such as figure 1 As shown in the structure, the original rectangular slot 1 is changed to pear-shaped slot 2 to increase the cross-sectional area of the stator teeth and reduce the magnetic flux density of the stator teeth; on the other hand, as image 3 The double squirrel-cage rotor structure shown is changed to Figure 5 For the single squirrel-cage rotor structure shown, the groove shape of the rotor blade is also determined by Figure 4 The groove shape of the double squirrel cage rotor shown is changed to Image 6 The single squirrel-cage rotor punching groove structure shown above, or other single squirrel-cage structures, such as convex shape, etc., can greatly reduce the magnetic flux density of the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com