Surface-treated steel sheet on which particulate tin is deposited and resin-coated steel sheet

A technology for surface treatment of steel plates and steel plates, applied to synthetic resin layered products, metal layered products, containers, etc., can solve the problems of hindering the adhesion of organic resin films, poor film adhesion, and difficulty in covering, and achieve excellent processing adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Next, the present invention will be specifically described using Examples 1 to 64 and Comparative Examples 1 to 23.

[0058] [Production of surface-treated steel sheets]

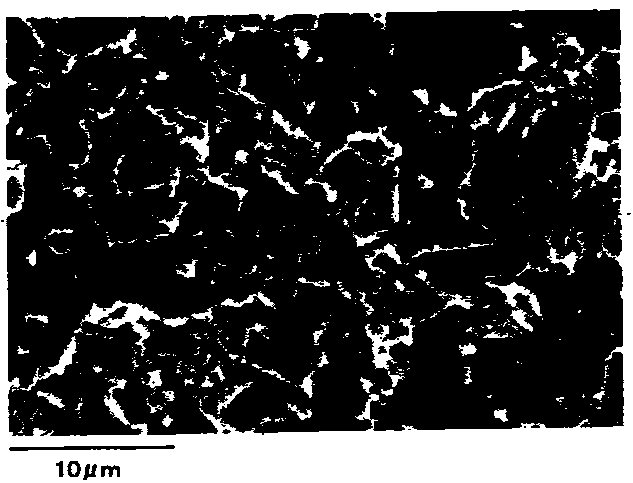

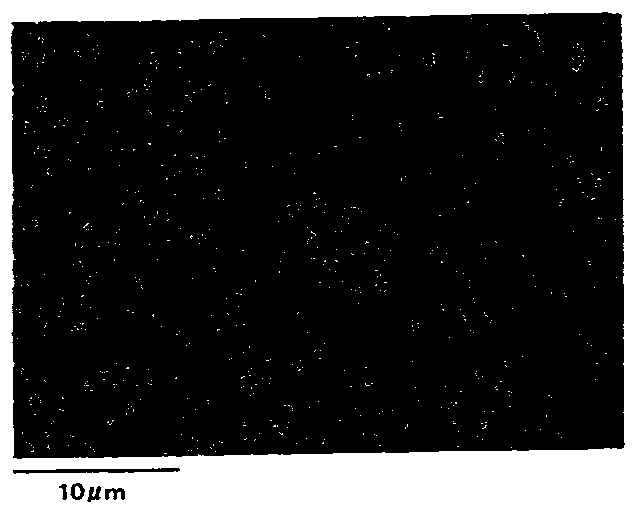

[0059] Using the low-carbon cold-rolled steel sheet shown in the column "Thickness" of Table 1, after performing electrolytic degreasing-water washing, sulfuric acid pickling-water washing in an alkaline aqueous solution, using a tin sulfate bath, tin plating conditions and Metallic tin particles were formed under the conditions shown in Tables 1 to 4, and samples were produced without tin melting treatment and with tin melting treatment. Next, the surface-treated steel sheet serving as the resin-laminated substrate was heated in three stages of 200°C, 220°C, and 250°C to laminate the resin layer on the granular metallic tin.

[0060]

[0061] Tin Sulfate Plating Bath Composition

[0062] Sulfuric acid concentration: 52g / L (20cc / L)

[0063] Tin sulfate concentration: 90g / L (50g / L as Sn)

[0064]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com