Metal surface treatment agent, surface treated steel material and surface treatment method thereof, and coated steel material and manufacturing method thereof

A metal surface treatment and steel technology, applied in the direction of metal material coating process, etc., can solve the problems of corrosion resistance and other problems, achieve good antirust ability, excellent processing adhesion, and change the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

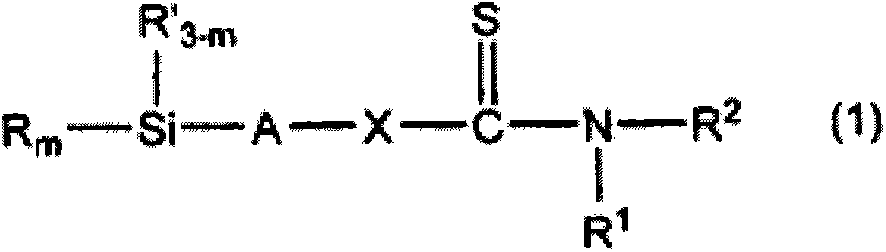

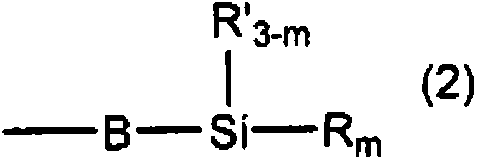

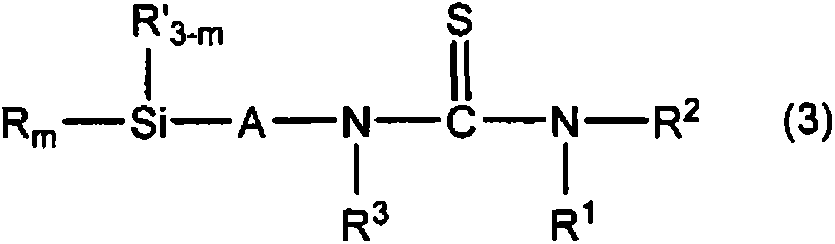

Method used

Image

Examples

Embodiment

[0135] Hereinafter, the present invention will be described in more detail with reference to synthesis examples, examples, and comparative examples, but the present invention is not limited to these examples. In addition, in the following examples, part means parts by mass, Me means methyl group, Et means ethyl group, Ph means phenyl group, and IR means an abbreviation of infrared spectroscopy.

Synthetic example 1

[0136] [Synthesis Example 1: Production method of organosilicon compound (8) (following formula (8))]

[0137] 358.6 g (2 mol) of 3-aminopropyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd., KBM-903) was added to a 1 L separate flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and the Add 146.2 g (2 mol) of methyl isothiocyanate, and stir at room temperature for 1 hour. Then, it was confirmed by IR measurement that the absorption peak derived from the isothiocyanate group of the raw material had completely disappeared, and the reaction was considered to be complete. The obtained product was a brown liquid, and when analyzed by gel permeation chromatography (GPC), the reaction product was a single product.

[0138] [chemical 15]

[0139]

Synthetic example 2

[0140] [Synthesis Example 2: Production method of organosilicon compound (9) (following formula (9))]

[0141] 358.6 g (2 mol) of 3-aminopropyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd., KBM-903) was added to a 1 L separate flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and the Add 174.3 g (2 mol) of ethyl isothiocyanate, and stir at room temperature for 1 hour. Then, it was confirmed by IR measurement that the absorption peak derived from the isothiocyanate group of the raw material had completely disappeared, and the reaction was considered to be complete. The obtained product was a brown liquid, and when analyzed by gel permeation chromatography (GPC), the reaction product was a single product.

[0142] [chemical 16]

[0143]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com