Method for producing surface-treated steel sheet

A technology of surface-treated steel plate and manufacturing method, which is applied in the field of surface-treated steel plate manufacturing, can solve the problems of resin peeling of tank body, increase the manufacturing cost of tinplate, problems of resin processing adhesion, etc., and achieve excellent adhesion and excellent processing adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] [Production of surface-treated steel sheets]

[0111] Sulfuric acid tin plating composition

[0112] Tin sulfate concentration (i.e. Sn concentration): 50g / L

[0113] Plating conditions

[0114] Plating current density: 5A / dm 2 ,

[0115] Plating bath temperature: 40°C,

[0116] Tin plating amount: 2.8

[0117] [Manufacturing of resin-coated steel sheets]

[0118] Next, a transparent non-stretched film of ethylene terephthalate-ethylene isophthalate copolymer (PETI) with a thickness of 28 μm was laminated on one side of the above-mentioned surface-treated steel sheet (the side inside the tank), and at the same time On the other side (the side outside the tank), laminate ethylene terephthalate-ethylene isophthalate copolymer (PETI) at a bonding temperature of 230°C. White pigment containing 20% by mass of titanium is white and the thickness is 16 μm. The white non-extended film of the resin film is cooled immediately after the resin film lamination is completed,...

Embodiment 2

[0120][Production of surface-treated steel sheets]

[0121] Sulfuric acid tin plating composition

[0122] Tin sulfate concentration (i.e. Sn concentration): 70g / L

[0123] Plating conditions

[0124] Plating current density: 7A / dm 2 ,

[0125] Plating bath temperature: 40°C,

[0126] Tin plating amount: 2.8

[0127] [Manufacturing of resin-coated steel sheets]

[0128] Carry out the same way as Example 1.

Embodiment 3

[0130] [Production of surface-treated steel sheets]

[0131] Sulfuric acid tin plating composition

[0132] Tin sulfate concentration (i.e. Sn concentration): 90g / L

[0133] Plating conditions

[0134] Electroplating current density: 10A / dm 2 ,

[0135] Plating bath temperature: 40°C,

[0136] Tin plating amount: 2.8

[0137] [Manufacturing of resin-coated steel sheets]

[0138] Carry out the same way as Example 1.

[0139]

[0140] Evaluations on the surface-treated steel sheets of Examples 1 to 3 will be described below.

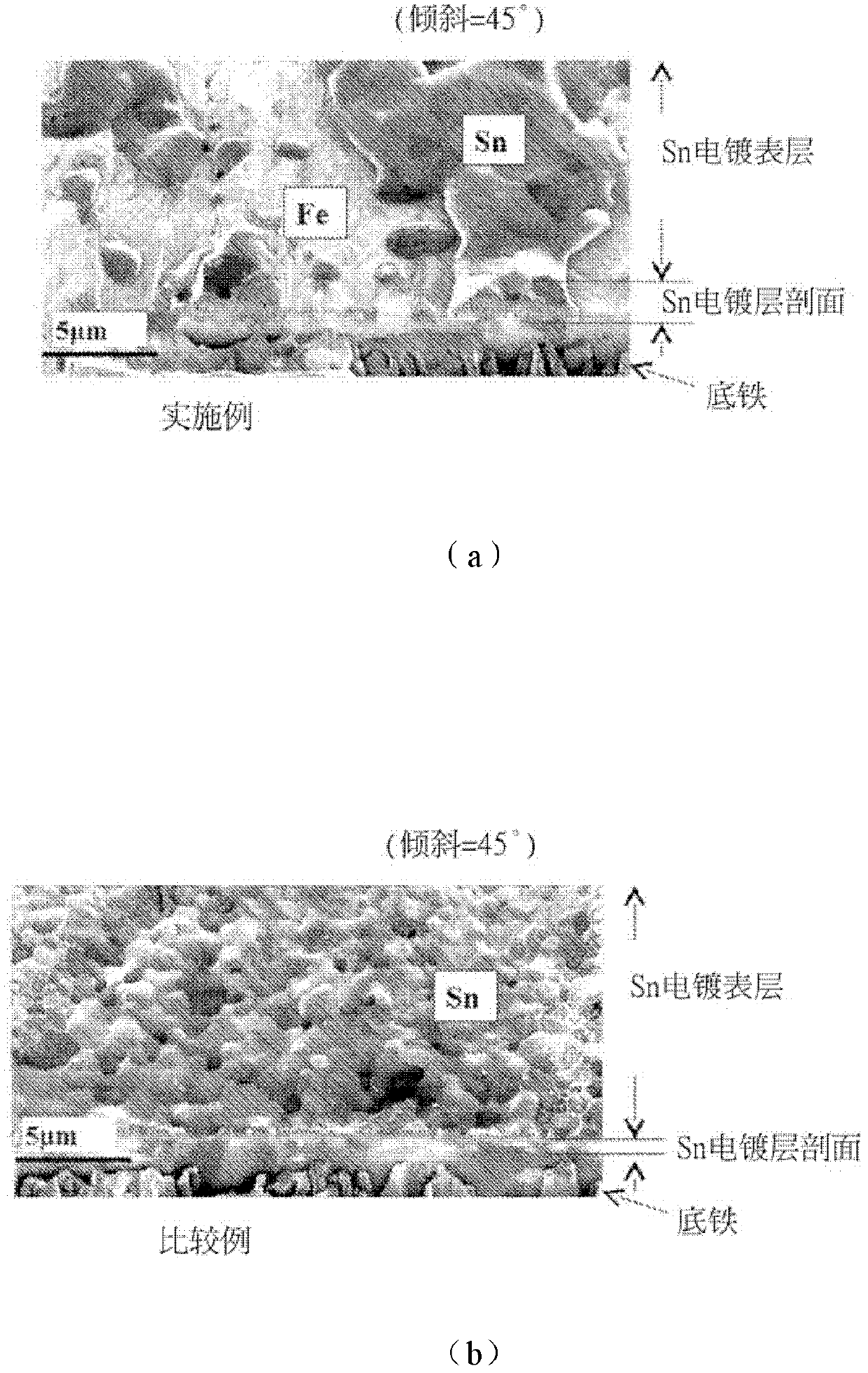

[0141] [surface observation]

[0142] figure 1 (a) shows the embodiment 1 of the present invention, the surface observation photo (SEM image) of the surface treated steel plate in which the exposed tin on the iron surface is deposited on the surface of the steel plate,

[0143] figure 1 (b) is a surface observation photograph of the surface-treated steel sheet of Comparative Example 1.

[0144] Such as figure 1 Shown in (a), on the surface-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com