Method for producing resin-coated metal plate

A manufacturing method and technology for metal plates, which can be used in bonding methods, metal layered products, chemical instruments and methods, etc., and can solve problems such as insufficient adhesiveness in film processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Hereinafter, the present invention will be specifically described through Examples 1-12 and Comparative Examples 1-3.

[0095] 〔Production of tin-plated steel sheet〕

[0096]Use the low-carbon cold-rolled steel sheet shown in the "plate thickness" column of Table 1, after electrolytic degreasing in alkaline aqueous solution-washing and sulfuric acid pickling-washing, use the acidic tin plating ferrostan method to make a plated steel plate under the conditions shown in Table 1. Melt treatment is performed after the tin layer.

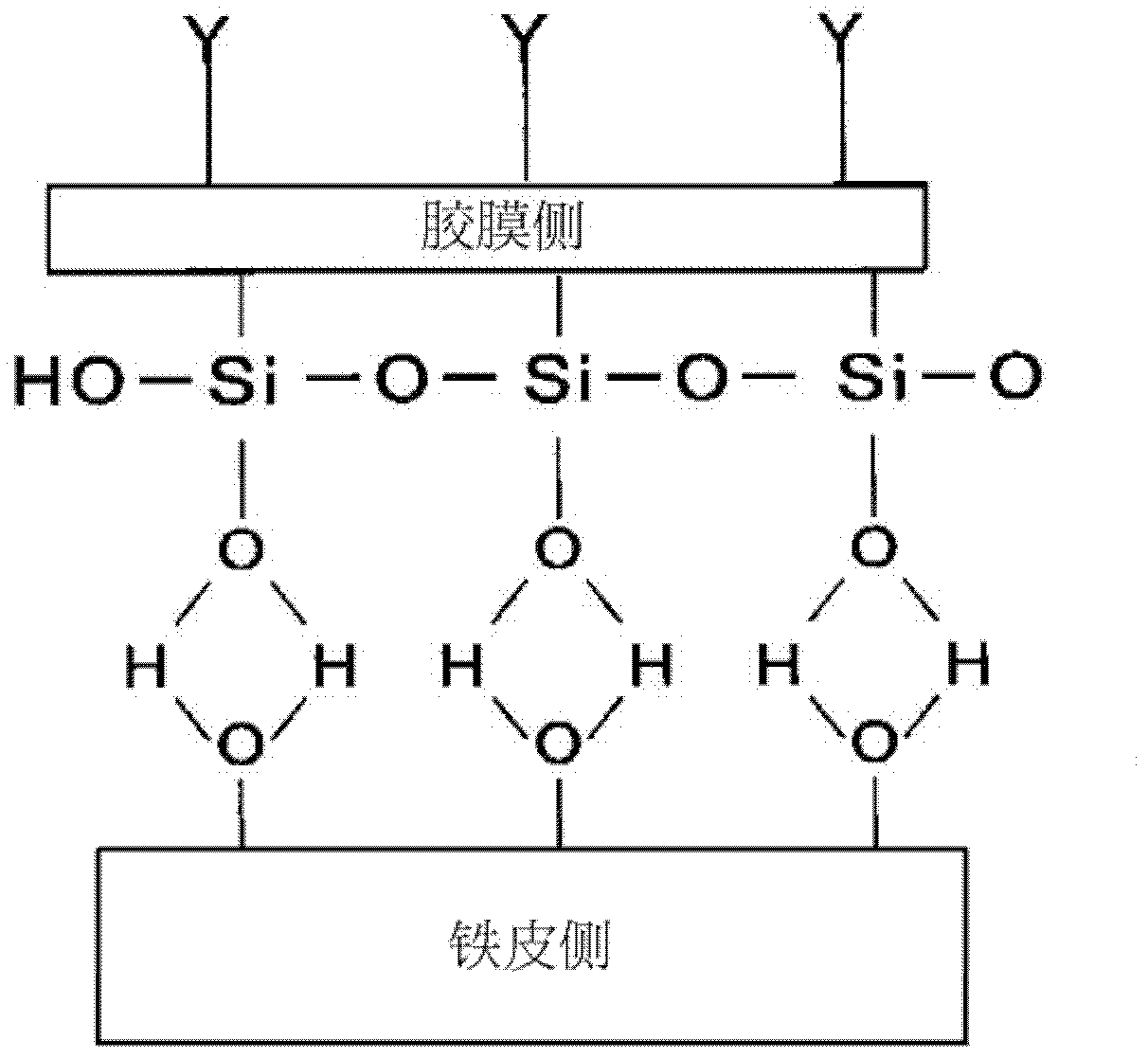

[0097] Next, smear the silane coupling agent on the top of the tin plating layer and let it dry to prepare the silane coupling agent smear layer with the Si adhesion amount shown in the examples and comparative examples in Table 1.

[0098] 〔Production of resin-coated metal sheets〕

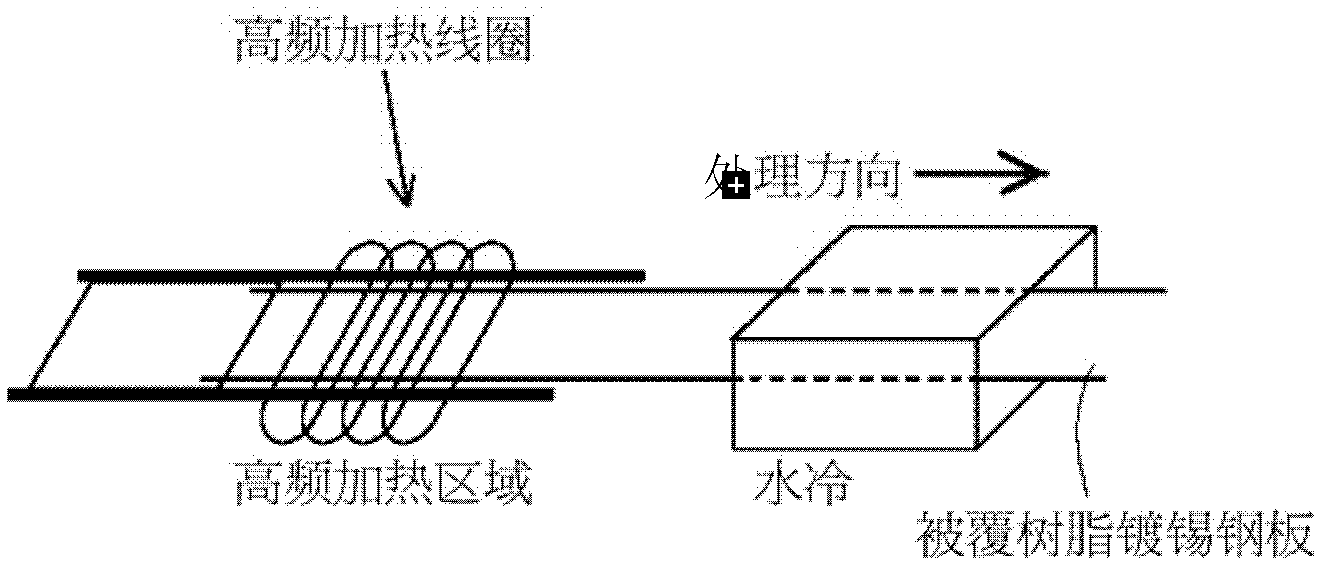

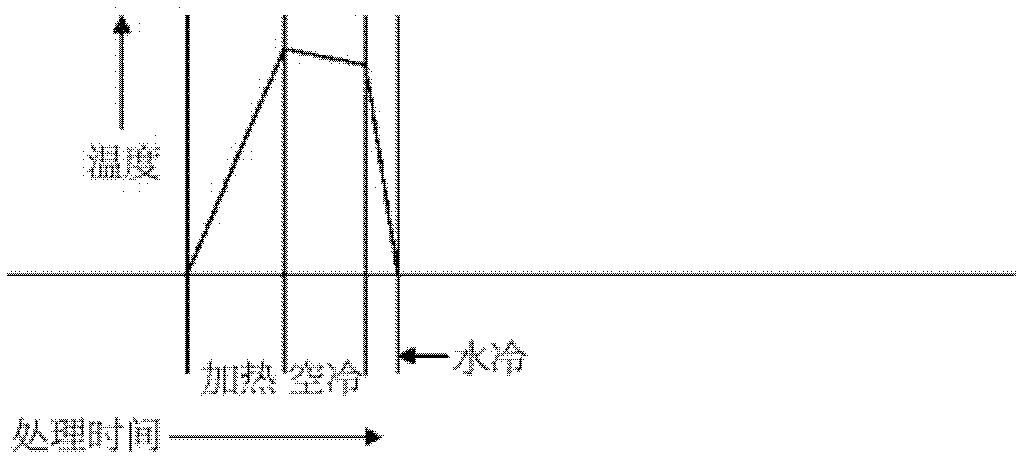

[0099] As shown in Examples 1 to 12 and Comparative Examples 1 to 3, according to the conditions listed in the table, a transparent non-stretchable adhesive film of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com