Split-type multi-stage tunnel strong magnetic gradient gap separation oxygen enrichment system

An oxygen-enriched system and split-flow technology, which is applied in the field of split-flow multi-stage tunnel strong magnetic gradient gap separation oxygen-enriched systems, can solve the problems of becoming smaller, affecting the gas separation effect, and becoming larger, so as to reduce control electrical appliances and operating costs. low, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

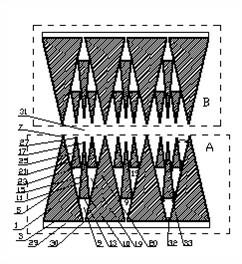

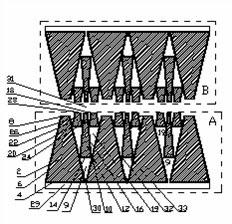

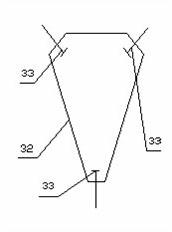

[0032] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a plurality of triangular or trapezoidal cross-sections with a small end and a large end (or one side is large and the other side is small and has a similar trapezoidal magnetic field distribution) elongated high-strength permanent magnets. (that is, the small head and the small head are piled up side by side, and the big head and the big head are piled up side by side), and are supported and fixed by the long hexagonal support frame 32; the two sides of the long bar magnet with one end small and the other end are N pole and S pole respectively, and one end is small and the other end is small. Large triangular or trapezoidal long bar magnets have different sizes, the largest set of one end is small and the other end is large. The base 3 of the triangular bar magnet 1 or the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com