Lifting device for transfer plate at the end of printing machine

A lifting device and printing machine technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of large investment in factories, difficult acceptance by enterprises, prolonging the flash drying time of flash ovens, and ink drying speed, etc. Achieve the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

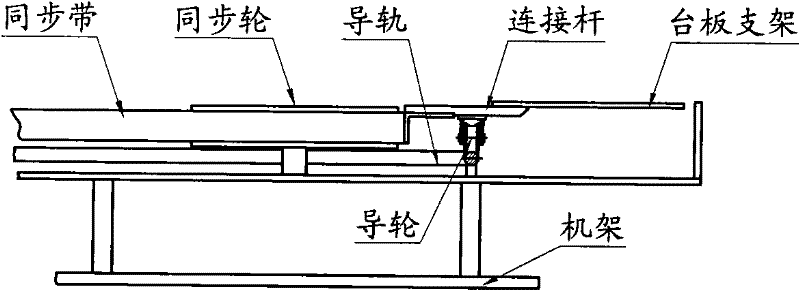

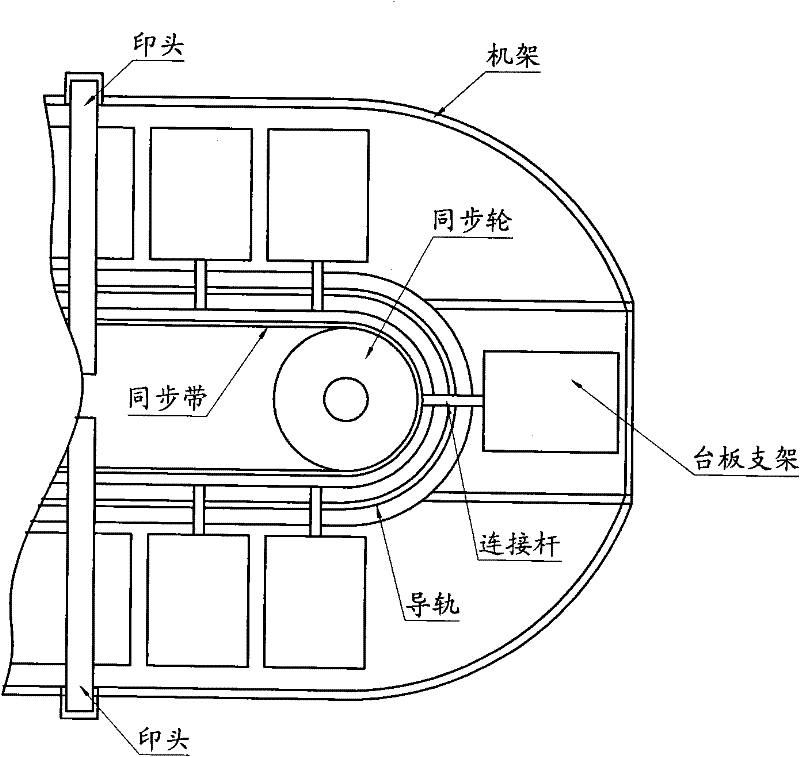

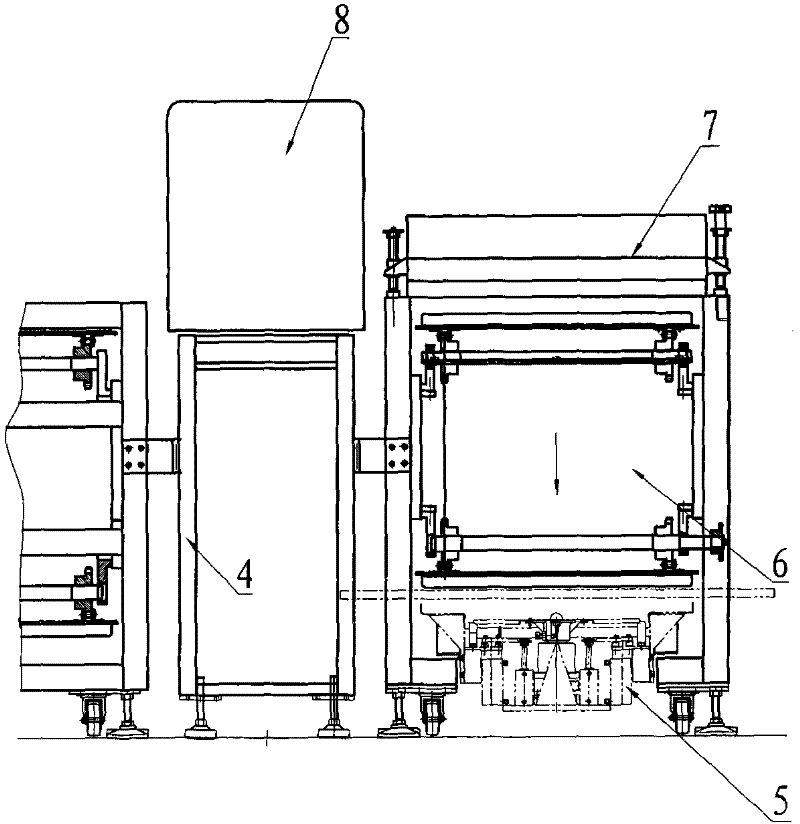

[0018] Embodiment 1: The transfer plate lifting device at the end of the printing machine, such as Figure 8 , Figure 9 , Figure 10 As shown, it includes a lifting tray 1, two cylinder units 2, a fixed support frame 3 and a frame 4, and the cylinder unit 2 includes a cylinder block 21 of the first cylinder, a piston rod 22 of the first cylinder, and a connecting plate 23 1. The cylinder body 24 of the second cylinder and the piston rod 25 of the second cylinder, one end of the fixed support frame 3 is fixedly connected with the cylinder body 21 of the first cylinder, and the other end is fixedly connected with the frame 4; one end of the connecting plate 23 is connected with the first cylinder The upper end surface of the piston rod 22 is fixedly connected, and the other end is fixedly connected with the cylinder body 24 of the second cylinder, and the lifting disc 1 is fixed on the piston rod 25 of the second cylinder, after the two cylinder units 2 are connected with the ...

Embodiment 2

[0019] Embodiment 2: Change the cylinder unit 2 in Embodiment 1 into a large-stroke cylinder, and the cylinder body is fixedly connected with the frame 4 through the fixed support frame 3; the lifting disc 1 is fixed on the piston rod of the cylinder.

[0020] The working process of the present invention is as follows: when the transfer plate 10 is sent from the outer conveying mechanism of the printing line to the print head 8 station at the end, after printing, it enters the flash oven 7 station for flash drying, and then enters the synchronous descending sequence after flash drying. Mechanism 6, when the transfer plate 10 is transported to the lowest position, the transfer plate lifting and steering device 5 will carry out the actions of receiving, descending, rotating 180°, and descending in sequence, so that the transfer plate 10 will be placed horizontally on the horizontal conveyor belt 11 to carry out translation, enter the below of the synchronous lifting mechanism 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com