Production method and device of refined glycerin in non-distillation techniques

A production method and technology of glycerin, which is applied in the field of refined glycerin production and equipment of non-rectification technology, can solve the problems of unsuitability for small and medium-sized enterprises, high energy consumption, huge system, etc., and achieve low construction cost, simple equipment structure and reliable operation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

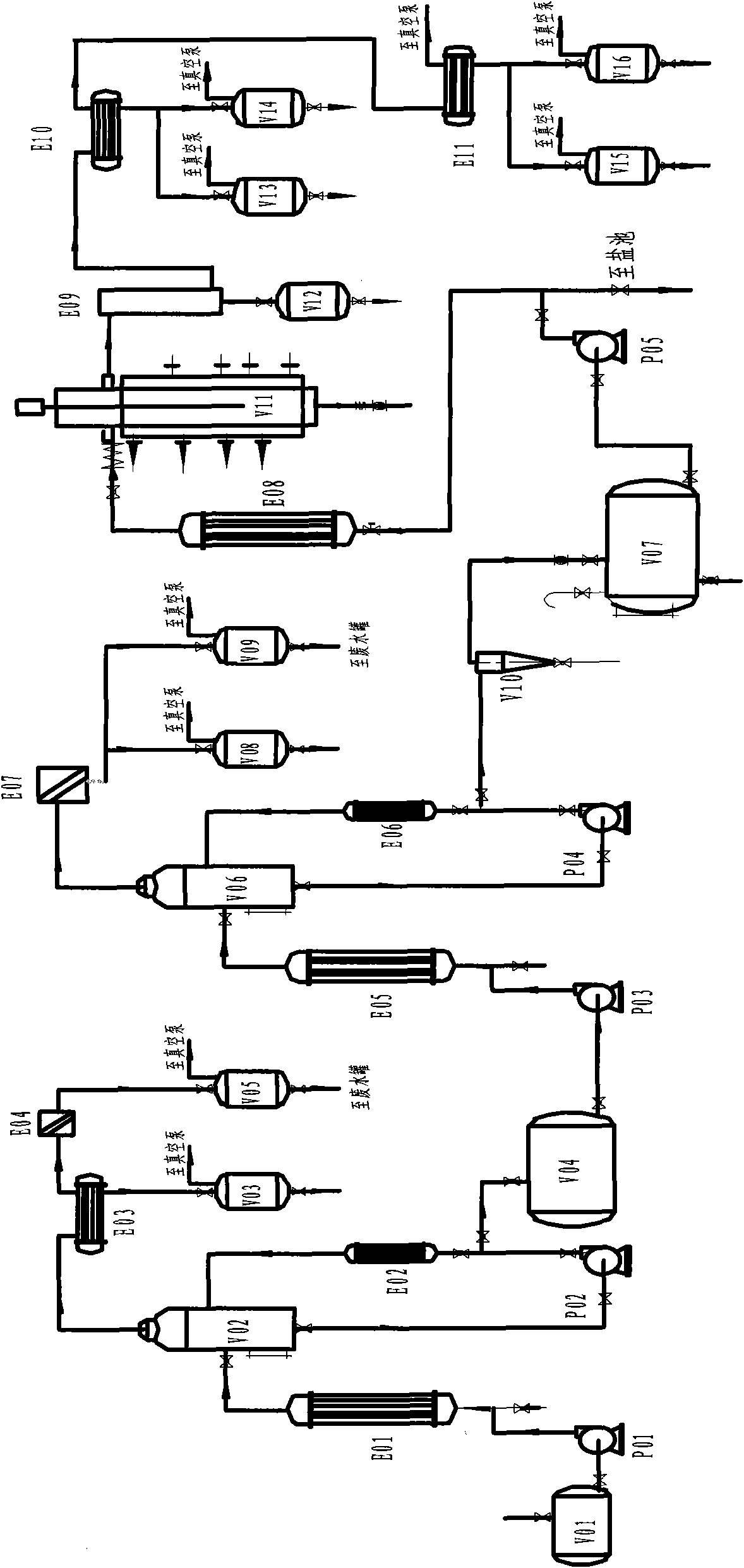

[0029] A non-distillation technology refined glycerin production method, using multi-stage flash dehydration, hydrocyclone separation to desalt, thin film evaporation refining, graded condensation methods to refine glycerin, specifically: crude glycerin is subjected to one-stage flash evaporation at ≤ 30kPa , the kettle liquid after the primary flash evaporation is partially heated and then continues to return to the primary flash tank for circulation, and the remaining part is subjected to secondary flash evaporation at ≤ 2kPa, and the kettle liquid after the secondary flash evaporation is partially heated and then re-enters the secondary The flash tank is circulated, and the remaining part enters the hydrocyclone for preliminary desalination, and then thin-film evaporation desalination refines the steam to obtain glycerol with a purity of ≥99.5%wt after multi-stage condensation. Combine below figure 1 Further explanation of the refining process:

[0030] 1) Primary flash ev...

Embodiment 2

[0037] A non-distillation technology refined glycerin production method, using multi-stage flash dehydration, hydrocyclone separation to desalt, thin film evaporation refining, graded condensation methods to refine glycerin, specifically: crude glycerin is subjected to one-stage flash evaporation at ≤ 30kPa , the kettle liquid after the primary flash evaporation is partially heated and then continues to return to the primary flash tank for circulation, and the remaining part is subjected to secondary flash evaporation at ≤ 2kPa, and the kettle liquid after the secondary flash evaporation is partially heated and then re-enters the secondary The flash tank is circulated, and the remaining part enters the hydrocyclone for preliminary desalination, and then thin-film evaporation desalination refines the steam to obtain glycerol with a purity of ≥99.5%wt after multi-stage condensation. The temperature during the primary flash evaporation is 140-150° C., and the water content in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com