Steam turbine oil

A technology of steam turbine oil and base oil, which is applied in the field of steam turbine oil, which can solve the problems of chaotic procurement cost of steam turbine oil quality management, and achieve the effects of improving profit margins, good filterability, and reducing oil change frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

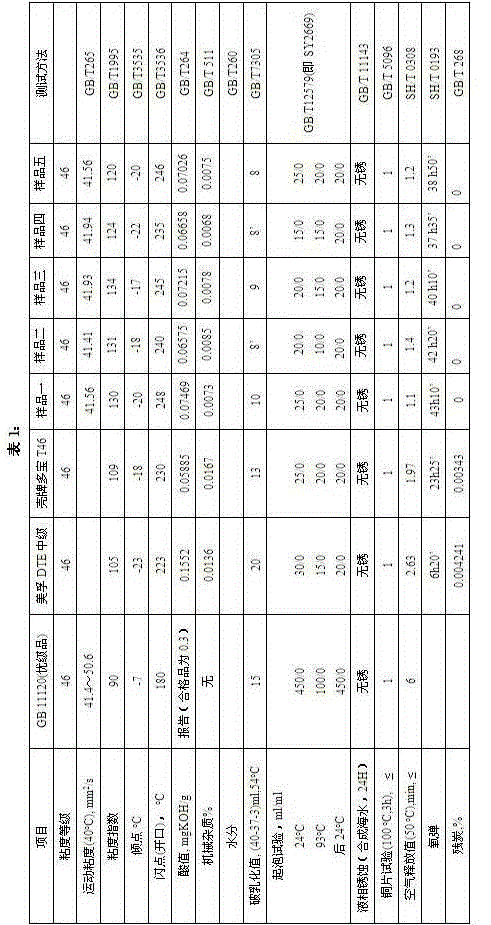

Examples

Embodiment 1

[0022] Group III base oil 99.24 wt%

[0023] Butyldiphenylamine 0.4 wt% as an amine antioxidant;

[0024] Sulfurized olefins as sulfur-containing extreme pressure antiwear additives 0.3 wt%;

[0025] Phosphate amine salt as ashless rust inhibitor 0.02 wt%;

[0026] Tolyltriazole derivatives as metal passivators 0.04 wt%.

[0027] Stir the above components at 50-80° C. for 1 to 5 hours, cool and fine filter to obtain Sample 1.

Embodiment 2

[0029] Group III base oil 99.229 wt%

[0030] Mixed butyl / ethyl alkylated diphenylamine 0.5 wt% as an amine antioxidant;

[0031] Ashless dithiocarbamate 0.2 wt% as sulfur extreme pressure antiwear additive;

[0032] Alkenyl succinate neutral barium naphthalenesulfonate 0.03 wt% as ashless rust inhibitor;

[0033] Tolyltriazole derivatives as metal deactivators 0.04 wt%;

[0034] Methylsiloxane mixture as defoamer 0.001 wt%.

[0035] The above-mentioned components were stirred at 50-80° C. for 1 to 5 hours, cooled and finely filtered to obtain sample 2.

Embodiment 3

[0037] Group III base oil 98.885 wt%

[0038] Diheptyldiphenylamine 0.4 wt% as an amine antioxidant;

[0039] Ashless dithiocarbamate 0.7 wt% as sulfur extreme pressure antiwear additive;

[0040] Alkenylsuccinic acid 0.01 wt% as an ashless rust inhibitor;

[0041] Thiadiazole derivatives as metal deactivators 0.01 wt%;

[0042] Methylsiloxane mixture as defoamer 0.005 wt%.

[0043] The above-mentioned components were stirred at 50-80° C. for 1 to 5 hours, cooled and finely filtered to obtain sample three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com