Milk protein blended regenerated cellulose fiber and its preparation process and application

A technology of regenerated cellulose and milk protein, applied in the field of cellulose fiber, can solve problems such as constraints, immature milk protein fiber and fabric preparation technology, affecting application and promotion, etc., achieve good permanence, increase product added value, prevent Effects of Radiation Damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

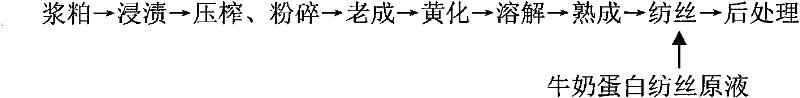

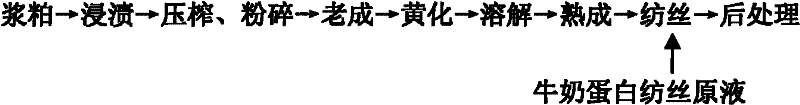

[0034] The preparation process of milk protein blended regenerated cellulose fiber comprises the following technical steps:

[0035] (1) pulp;

[0036] (2) Dipping;

[0037] (3) Squeeze and crush;

[0038] (4) mature;

[0039] (5) Yellowing;

[0040] (6) dissolve;

[0041] (7) Mature;

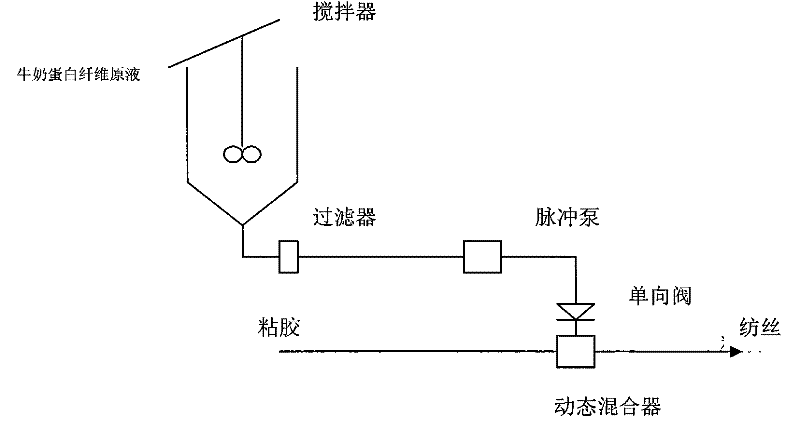

[0042] (8) Preparation of milk protein spinning dope;

[0043] (9) spinning;

[0044] (10) Finished product after post-processing.

[0045] In the above-mentioned technical scheme, the preparation of the milk protein spinning stock solution described in step (8) comprises the following steps:

[0046] (1) The milk casein is pulverized at low temperature to a particle size of 0.5 microns;

[0047] (2) Heating the NaOH alkali solution with 10% weight concentration to 40° C., and adding a crosslinking agent;

[0048] (3) adding the milk casein obtained in the step (1) into the NaOH alkali solution in the step (2) for fully dissolving to obtain the milk protein spinning stock solution;

...

Embodiment 2

[0054] The preparation process of milk protein blended regenerated cellulose fiber comprises the following technical steps:

[0055] (1) pulp;

[0056] (2) Dipping;

[0057] (3) Squeeze and crush;

[0058] (4) mature;

[0059] (5) yellowing;

[0060] (6) dissolve;

[0061] (7) Mature;

[0062] (8) Preparation of milk protein spinning dope;

[0063] (9) spinning;

[0064] (10) Finished product after post-processing.

[0065] In the above-mentioned technical scheme, the preparation of the milk protein spinning stock solution described in step (8) comprises the following steps:

[0066] (1) The milk casein is pulverized at low temperature to a particle size of 0.7 microns;

[0067] (2) Heating the NaOH solution with a concentration of 10% by weight to 43° C., and adding a crosslinking agent;

[0068] (3) adding the milk casein obtained in the step (1) into the alkali solution in the step (2) for fully dissolving to obtain the milk protein spinning stock solution;

[00...

Embodiment 3

[0074] The preparation process of milk protein blended regenerated cellulose fiber comprises the following technical steps:

[0075] (1) pulp;

[0076] (2) Dipping;

[0077] (3) Squeeze and crush;

[0078] (4) mature;

[0079] (5) yellowing;

[0080] (6) dissolve;

[0081] (7) Mature;

[0082] (8) Preparation of milk protein spinning dope;

[0083] (9) spinning;

[0084] (10) Finished product after post-processing.

[0085] In the above-mentioned technical scheme, the preparation of the milk protein spinning stock solution described in step (8) comprises the following steps:

[0086] (1) Low-temperature pulverization of milk casein to a particle size of 0.8 microns;

[0087] (2) heating the alkali solution with 10% weight concentration to 45° C., and adding a crosslinking agent;

[0088](3) adding the milk casein obtained in the step (1) into the alkali solution in the step (2) for fully dissolving to obtain the milk protein spinning stock solution;

[0089] Wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com