A cantilever diagonal brace used for pouring bridge pier cover beams

A technology for piers and beams, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as affecting the external appearance of piers, increase construction procedures, increase construction costs, etc., to reduce manual labor, reduce safety hazards, and speed up The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

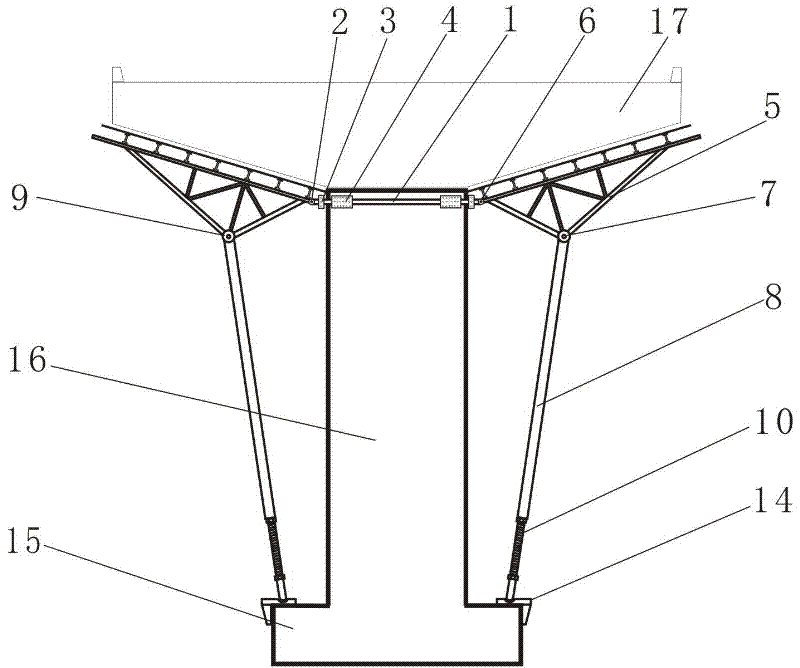

[0024] Type A: Cantilever braces for pouring a pier cap beam

[0025]It is composed of two pier-holding beams 1, a pair of tripod load-bearing joists 5, a pair of ball-end threaded diagonal braces 8, and a pair of ball-end bases 14; Clamp the pier 16 horizontally, and the clamp positioning pull rods respectively pass through the screw holes 3 at both ends of the two pier clamping beams, and are fixed by high-strength pull rod bolts, and fix the two pier clamping beams 1 on the upper end cover beam of the pier 16. Position: The rotatable connection hole 6 at the large acute angle end of the load-bearing joist of the tripod on the left side and the rotatable connection hole 2 set on the left end of the pier clamping beam are fixed by rotating bolts, and the rotatable connection at the obtuse angle end of the load-bearing joist of the tripod The hole 7 and the rotatable connection hole 9 at the top of the ball threaded diagonal strut 8 are fixed by rotating bolts, and the threa...

Embodiment 2

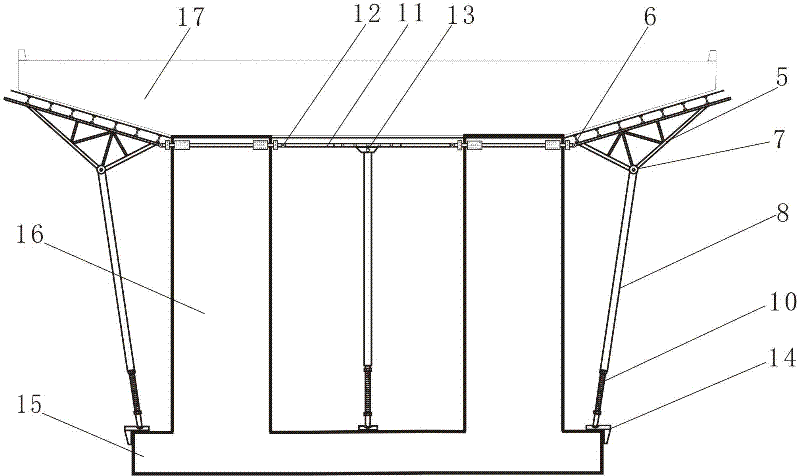

[0027] Type B: Cantilever braces for pouring two pier cap beams

[0028] The structure of this type of cantilever brace bracket is basically the same as that of Embodiment 1, the only difference being that in the case of two piers, the lower end of the cover beam 17 to be poured at the top of the central part of the two piers is provided with horizontal load-bearing joists 11 on the left and right, Horizontally support the steel formwork for the girder to be poured between the two piers; in the middle section of the horizontal load-bearing joist, there are vertically arranged ball-end threaded diagonal braces 8 to support the steel formwork for the girder to be poured between the two piers. The horizontal load-bearing joist 11 below the formwork; a ball base 14 is provided on the central bottom cap of the two piers to support the ball threaded diagonal brace 8;

[0029] Connecting holes 12 are provided on both ends of the horizontal load-bearing joist 11, length adjustment s...

Embodiment 3

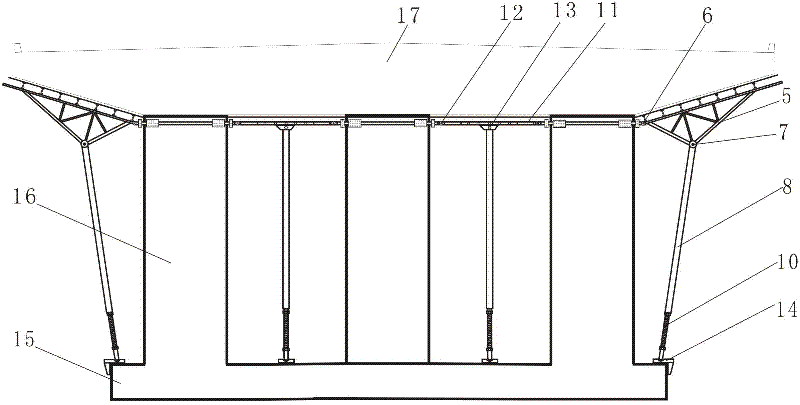

[0032] Type C: Cantilever braces for pouring three pier cap beams

[0033] The structure of this type of cantilever brace is basically the same as that of Embodiments 1 and 2, the only difference being that in the case of three piers, the lower end of the cover beam 17 to be poured between the middle pier and the top of the right pier is provided with Horizontal load-bearing joist 11, horizontally supports the steel formwork for the pouring cover beam between the middle pier and the right pier; in the middle section of the horizontal load-bearing girder, ball-threaded diagonal braces 8 are vertically arranged up and down to support the middle pier The horizontal load-bearing joist 11 under the steel formwork of the cap beam to be poured between the right pier and the right pier; a ball base 14 is provided on the central bottom cap of the middle pier and the right pier to support the ball threaded diagonal brace 8;

[0034] The cover beam cantilever diagonal bracing bracket o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com