A battery temperature sensing device and its preparation method

A technology of temperature sensing device and storage battery, which is applied in the direction of using electric devices, measuring devices, thermometers using electric/magnetic components directly sensitive to heat, etc., can solve the problems of low control accuracy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

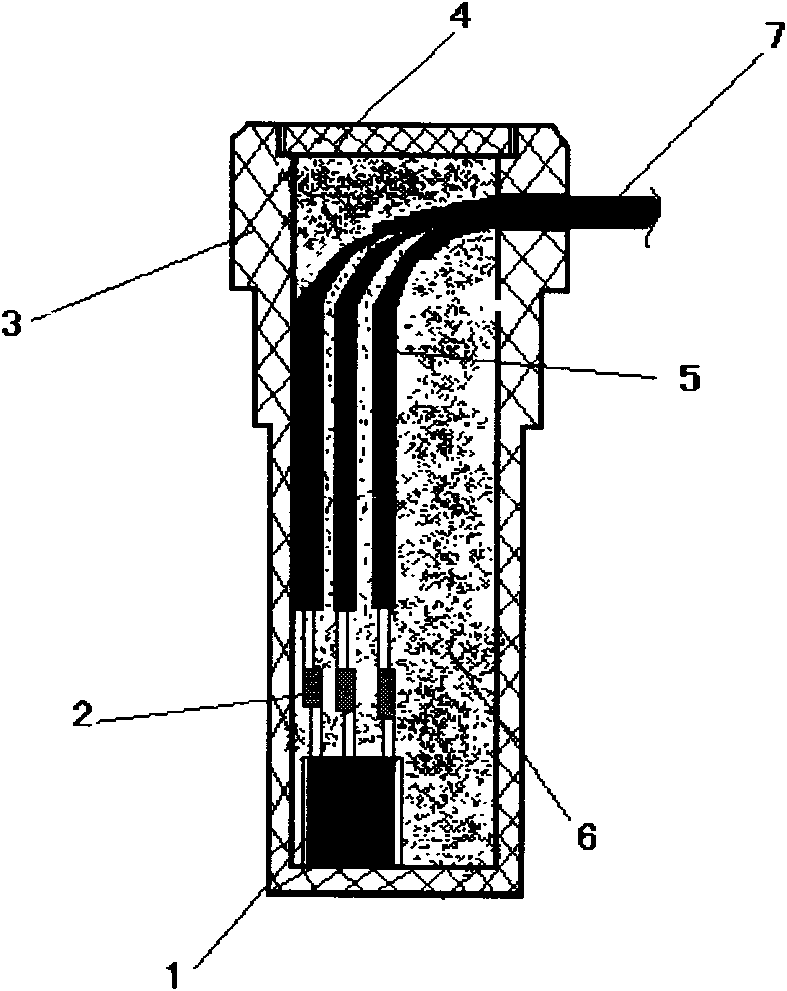

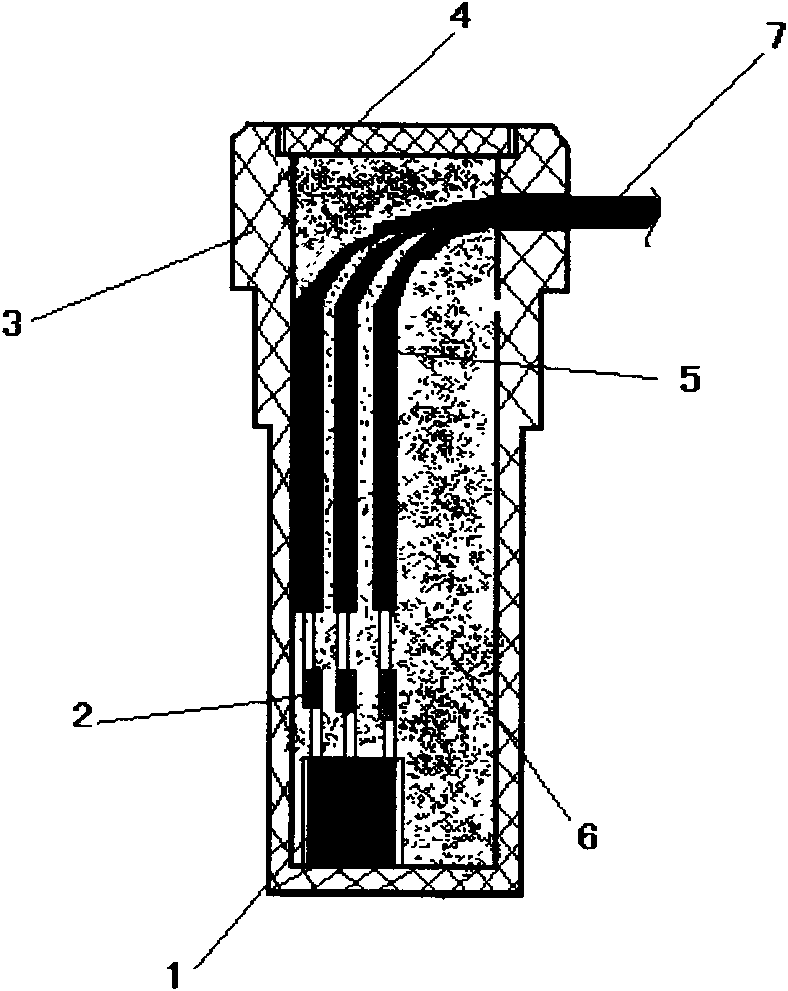

[0023] The battery temperature sensing device of this embodiment includes a housing 3, a cover 4, a wire 5, and a sensor chip 1. The sensor chip 1 is located at the bottom of the housing 3, and the upper end of the sensor chip 1 is provided with chip pins. The pin is welded with the wire 5 to form the chip pin and wire welding place 2; a part of the wire 5 passes through the temperature sensing device, and the part that passes through the temperature sensing device is provided with a heat shrink tube 7; the casing 3 is equipped with potting Material 6.

[0024] The bottom of the temperature sensing device is a cylinder, and the top is a hexagonal prism. The shell 3 is made of PVC polyvinyl chloride engineering plastic.

[0025] The sensor chip 1 is a DS18B20 digital temperature sensor, and the potting material includes epoxy resin, curing agent, thermal conductive material and filler.

[0026] The mass ratio of epoxy resin and curing agent is 7:3, epoxy resin is epoxy resin 618; cur...

Embodiment 2

[0035] The battery temperature sensing device of this embodiment includes a housing 3, a cover 4, a wire 5, and a sensor chip 1. The sensor chip 1 is located at the bottom of the housing 3, and the upper end of the sensor chip 1 is provided with chip pins. The pin is welded with the wire 5 to form the chip pin and wire welding place 2; a part of the wire 5 passes through the temperature sensing device, and the part that passes through the temperature sensing device is provided with a heat shrink tube 7; the casing 3 is equipped with potting Material 6.

[0036] The bottom of the temperature sensing device is a cylinder, and the top is a hexagonal prism. The shell 3 is made of PVC polyvinyl chloride engineering plastic.

[0037] The sensor chip 1 is a DS18B20 digital temperature sensor, and the potting material includes epoxy resin, curing agent, thermal conductive material and filler.

[0038] The mass ratio of epoxy resin and curing agent is 3:2, the epoxy resin is epoxy resin 618;...

Embodiment 3

[0050] The battery temperature sensing device of this embodiment includes a housing 3, a cover 4, a wire 5, and a sensor chip 1. The sensor chip 1 is located at the bottom of the housing 3, and the upper end of the sensor chip 1 is provided with chip pins. The pin is welded with the wire 5 to form the chip pin and wire welding place 2; a part of the wire 5 passes through the temperature sensing device, and the part that passes through the temperature sensing device is provided with a heat shrink tube 7; the casing 3 is equipped with potting Material 6.

[0051] The bottom of the temperature sensing device is a cylinder, and the top is a hexagonal prism. The shell 3 is made of PVC polyvinyl chloride engineering plastic.

[0052] The sensor chip 1 is a DS18B20 digital temperature sensor, and the potting material includes epoxy resin, curing agent, thermal conductive material and filler.

[0053] The mass ratio of epoxy resin and curing agent is 6:5, epoxy resin is epoxy resin 618; cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com