Trench vmos transistor manufacturing method

A manufacturing method and transistor technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as aluminum puncture, and achieve the effect of increasing the thickness of the metal layer and eliminating the defects of aluminum puncture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

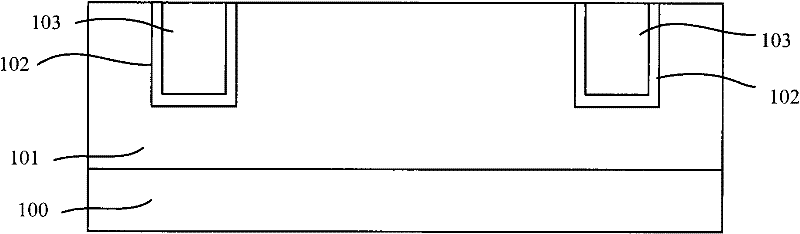

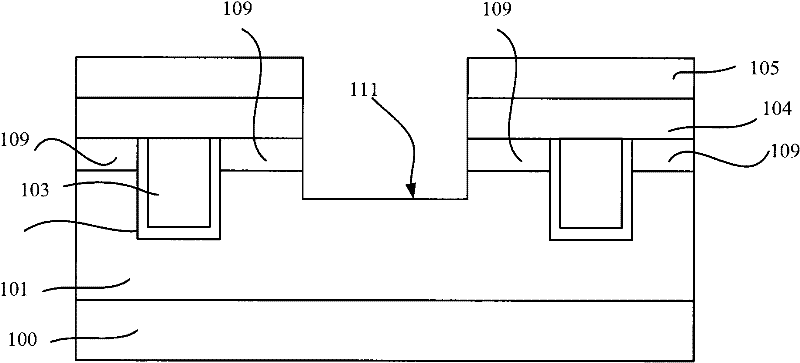

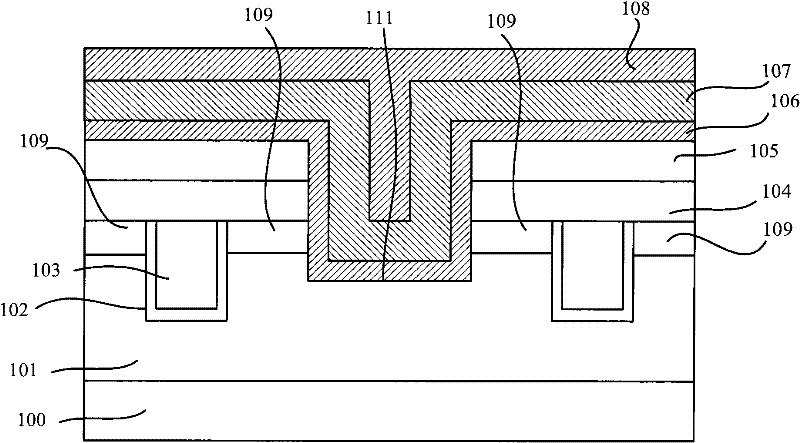

[0028] The inventors have found that the contact holes of existing trench VMOS transistors have relatively large diameters, generally greater than or equal to 0.6 microns, and in some cases up to 2 microns. In the prior art, only chemical vapor deposition or physical vapor deposition is used to form the barrier metal layer on the bottom and sidewall of the trench. Among them, the uniformity of the physical vapor deposition method when depositing the barrier metal layer is not good, so that the formed barrier metal layer is not good at the step of the contact hole, that is, the coverage of the barrier metal layer at the junction of the side wall and the bottom of the contact hole is not good. Well, due to the subsequent high temperature (300-400 degrees Celsius) fabrication of the metal interconnect layer and the metal alloy process, the aluminum of the metal interconnect layer penetrates into the epitaxial layer at the junction of the side wall and the bottom of the contact hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com