A vehicle power battery module

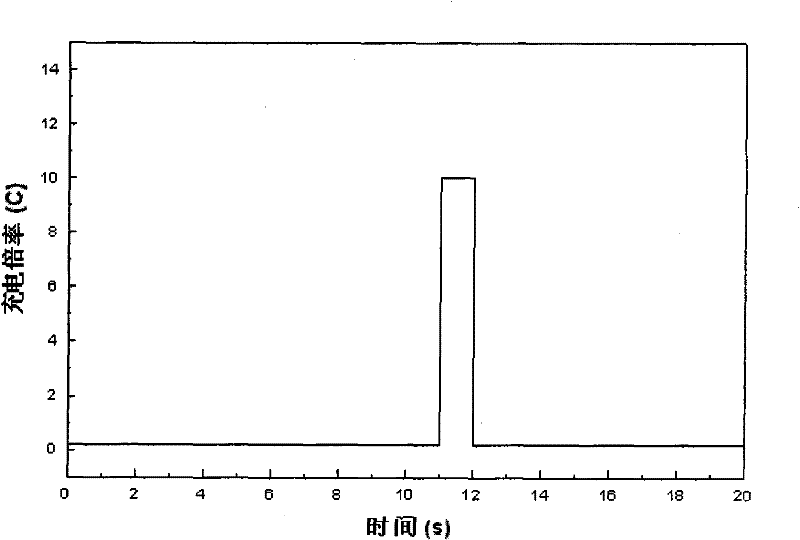

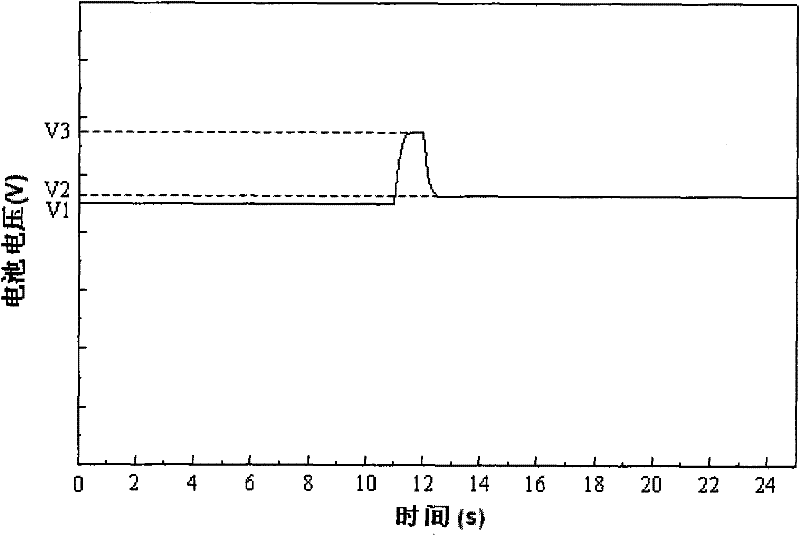

A technology for power batteries and power battery packs, which is applied in battery electrodes, secondary battery repair/maintenance, secondary battery charging/discharging, etc., and can solve the problem of aggravated electrolyte side reactions, battery damage, and affecting battery safety cycle performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the single battery of the present invention is carried out according to the methods known to those skilled in the art. Generally speaking, the method includes sequentially winding the positive electrode, the negative electrode and the separator between the positive electrode and the negative electrode to form a pole core, and the pole core Putting it into a battery case, adding electrolyte, and then sealing, wherein the negative electrode includes a current collector and a negative active material loaded on the current collector, wherein the negative active material is the negative active material provided by the present invention. Among them, the methods of winding and sealing are well known to those skilled in the art. The amount of electrolyte used is conventional.

[0034] Single cells with different polarization internal resistances were prepared by selecting different positive and negative electrode materials, particle sizes of materials,...

Embodiment 1

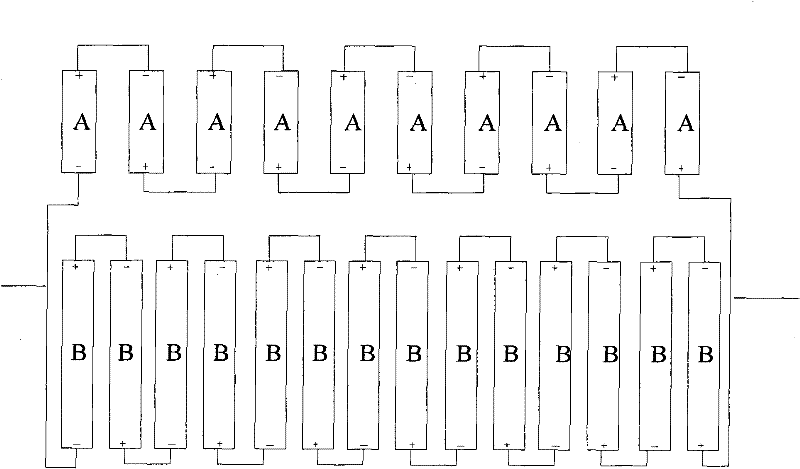

[0041] Take 10 power single batteries a in series to form a power battery pack A, take 14 pulse buffer single batteries b in series to form a pulse buffer battery pack B, and connect the power battery pack A and pulse buffer battery pack B in parallel to form a battery module AB.

Embodiment 2

[0043] Take 10 power single batteries a in series to form a power battery pack A, take 14 pulse buffer single batteries c in series to form a pulse buffer battery pack C, and connect the power battery pack A and pulse buffer battery pack C in parallel to form a battery module AC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com