Protective cover for constant velocity universal joint and constant velocity universal joint

A technology of constant velocity universal joints and protective covers, which is applied in the direction of elastic couplings, engine seals, engine components, etc., can solve the problems of snake belly depression and difficulty in ensuring the deformation state of protective covers, etc., to improve wear resistance, Excellent durability and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

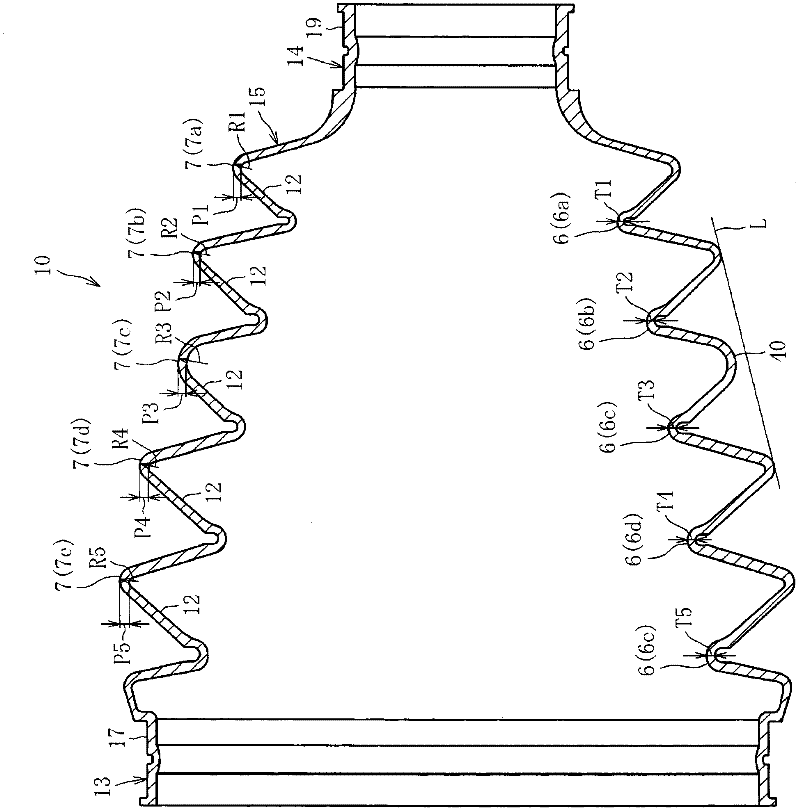

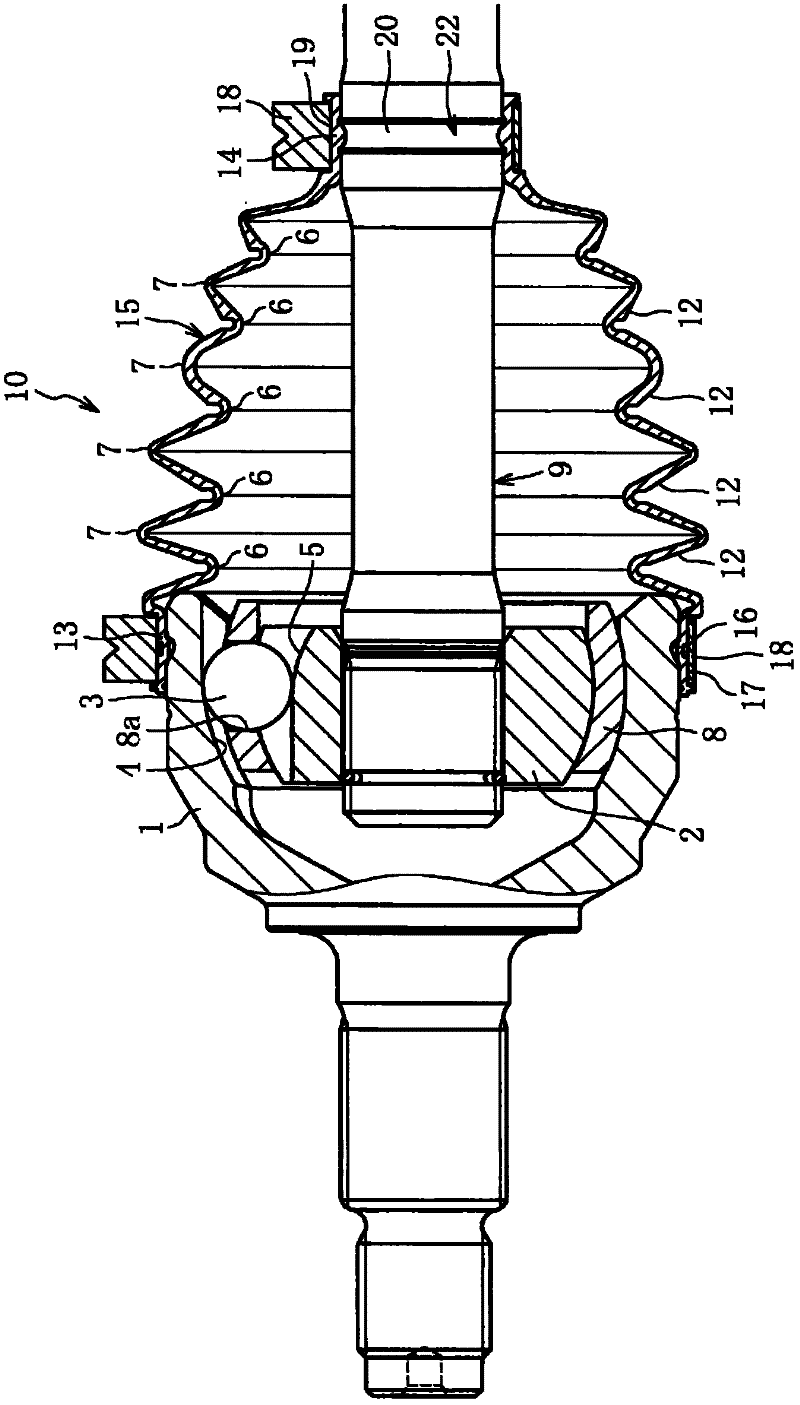

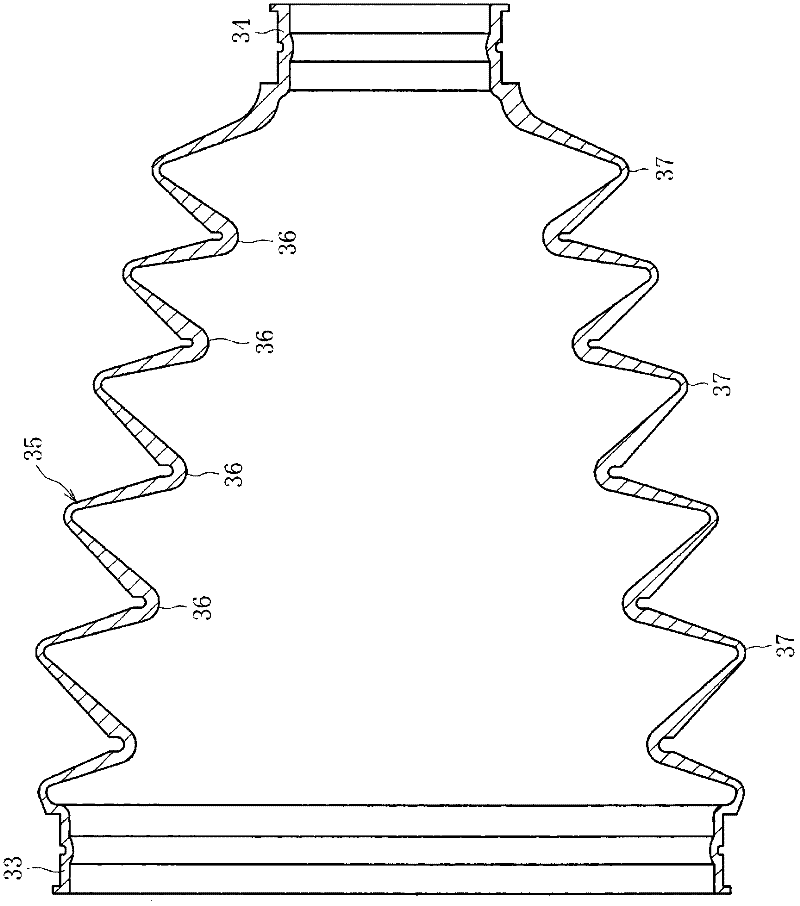

[0035] Below, combine Figure 1 ~ Figure 3 Embodiments of the present invention will be described. figure 1 Indicates the protective cover for constant velocity universal joints according to the present invention, figure 2 Indicates a constant velocity universal joint using a protective cover for a constant velocity universal joint.

[0036] like figure 2 As shown, the constant velocity universal joint is composed of the following parts: the outer ring 1 as the outer joint part is formed with a plurality of guide grooves (raceway grooves) 4 in the axial direction on the inner peripheral surface; The inner ring 2 as an inner joint part of the guide groove (raceway groove) 5; a plurality of balls 3 arranged on the ball raceway formed by the cooperation of the guide groove 4 of the outer ring 1 and the guide groove 5 of the inner ring 2; And a spacer 8 (cage) having a pocket 8a for accommodating the ball 3 and the like. In addition, a rotating shaft 9 is connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com