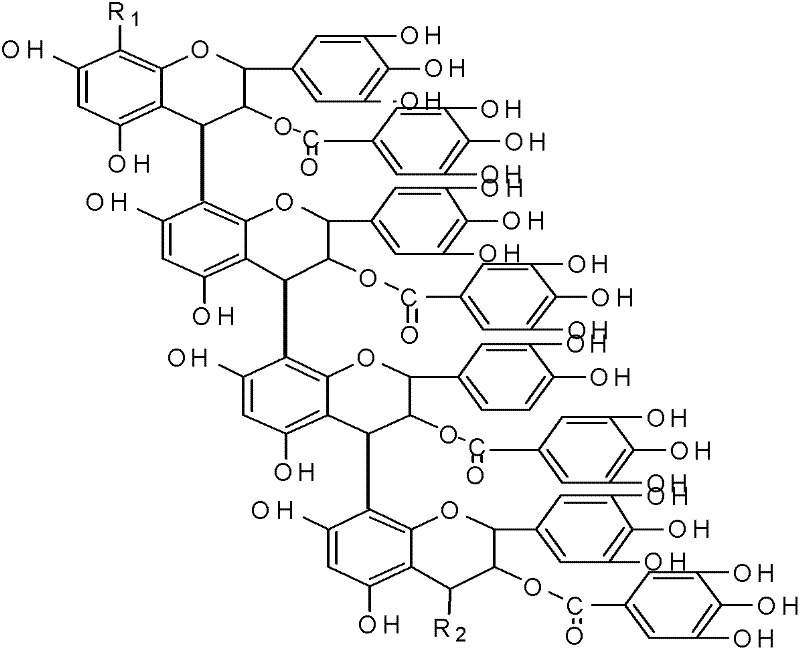

A kind of preparation method of activated carbon-persimmon tannin composite adsorbent

A composite adsorption and activated carbon technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve difficult metal ion removal problems, achieve low cost, improve purity quality, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

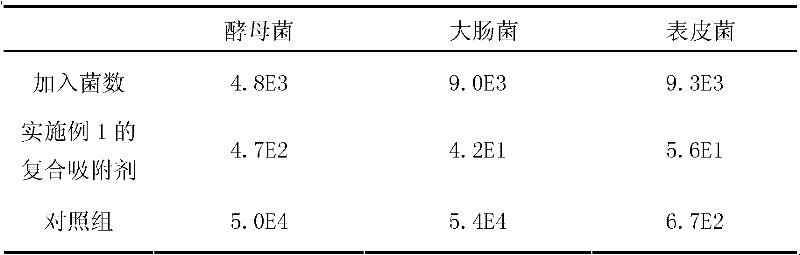

Examples

Embodiment 1

[0026] A preparation method of activated carbon-persimmon tannin composite adsorbent, which comprises the following steps:

[0027] 1) Pretreatment of activated carbon: ①Add 100g of activated carbon to 500ml of distilled water at 95-100°C and stir for 1h, then stir for 1h (this stirring is to continue stirring for 1h after the heating is stopped, in order to achieve the purpose of sufficient water washing, and the temperature and There are no strict requirements;); the solid is obtained by suction filtration; ② Pickling: add 250 ml of hydrochloric acid solution with a concentration of 5 to 6 mg / L to the obtained solid, heat to 90 to 100 ° C and stir for 1 hour, then stand for 24 hours. Wash with distilled water for 3 to 5 times until the pH of the final rinse is 5.0 to 6.0;

[0028] ③ The pickling process in the above step ② is repeated 3 times;

[0029] 4. The solid obtained after pickling is dried to constant weight in a 105 ℃ oven to obtain the treated activated carbon for...

Embodiment 2

[0034] A preparation method of activated carbon-persimmon tannin composite adsorbent, which comprises the following steps:

[0035] 1) pretreatment of activated carbon: the pickling process of step 2 is repeated 4 times, and the rest are the same as step 1 of embodiment 1);

[0036] 2) Magnetic stirring for 12h, and the rest are the same as step 2) of Example 1.

Embodiment 3

[0038] A preparation method of activated carbon-persimmon tannin composite adsorbent, which comprises the following steps:

[0039] 1) Pretreatment of activated carbon: ① Add 100 g of activated carbon to 500 ml of distilled water, boil and stir for 1 hour, and then stir for 1 hour; suction filtration to obtain solid; ② Pickling: add 250 ml of hydrochloric acid with a concentration of 5 to 6 mg / L to the obtained solid The solution was heated to 90-100 °C and stirred for 1 h, then stood for 24 h, and was washed with distilled water 3-5 times by suction filtration until the pH of the final rinse solution was 5.0-6.0;

[0040] ③ The pickling process of the above step ② is repeated 5 times;

[0041] 4. The solid obtained after pickling is dried to constant weight in a 95°C oven to obtain the treated activated carbon for subsequent use;

[0042] 2) Magnetic stirring for 24h, drying in an oven at 85°C, and the rest are the same as in step 2) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com