A rapid sedimentation and concentration tank for tailings sewage

A technology for concentrating tanks and sewage, which is applied in the direction of sedimentation and separation, mining wastewater treatment, water/sewage treatment, etc. It can solve the problems of large area of concentration tank, low treatment efficiency, inconvenient operation, etc., and achieves low use cost and high treatment efficiency. The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described in detail above in conjunction with the accompanying drawings and specific embodiments.

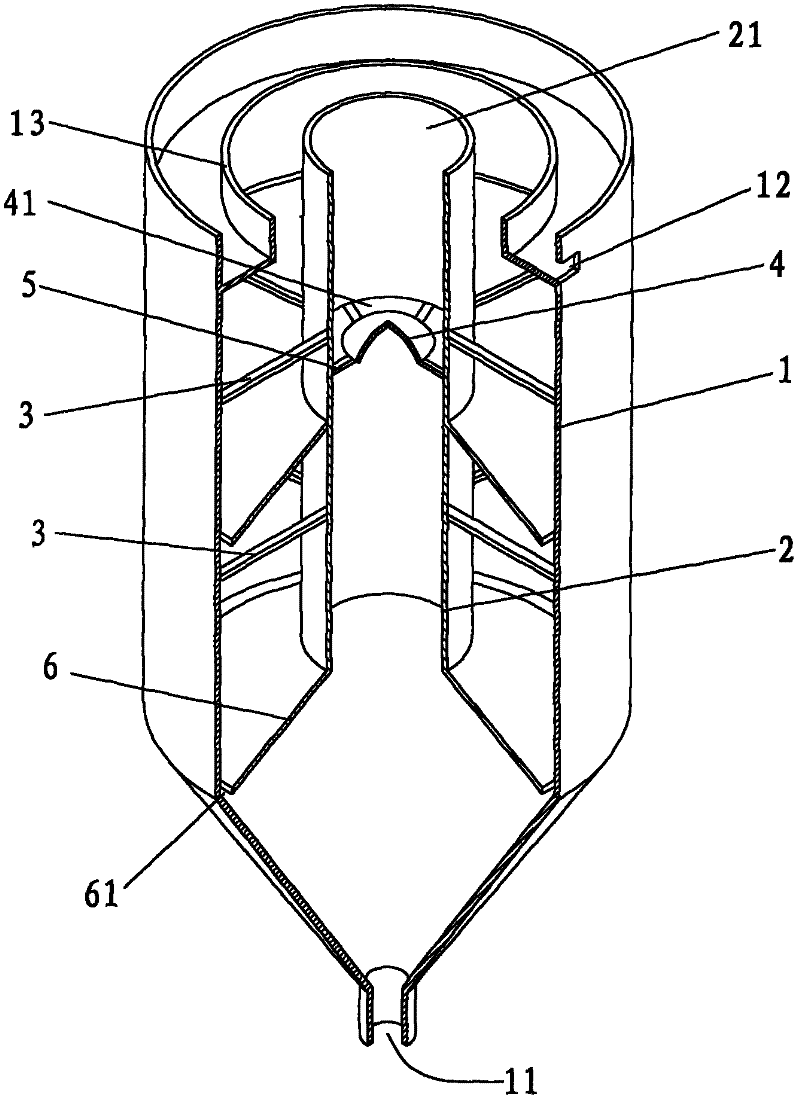

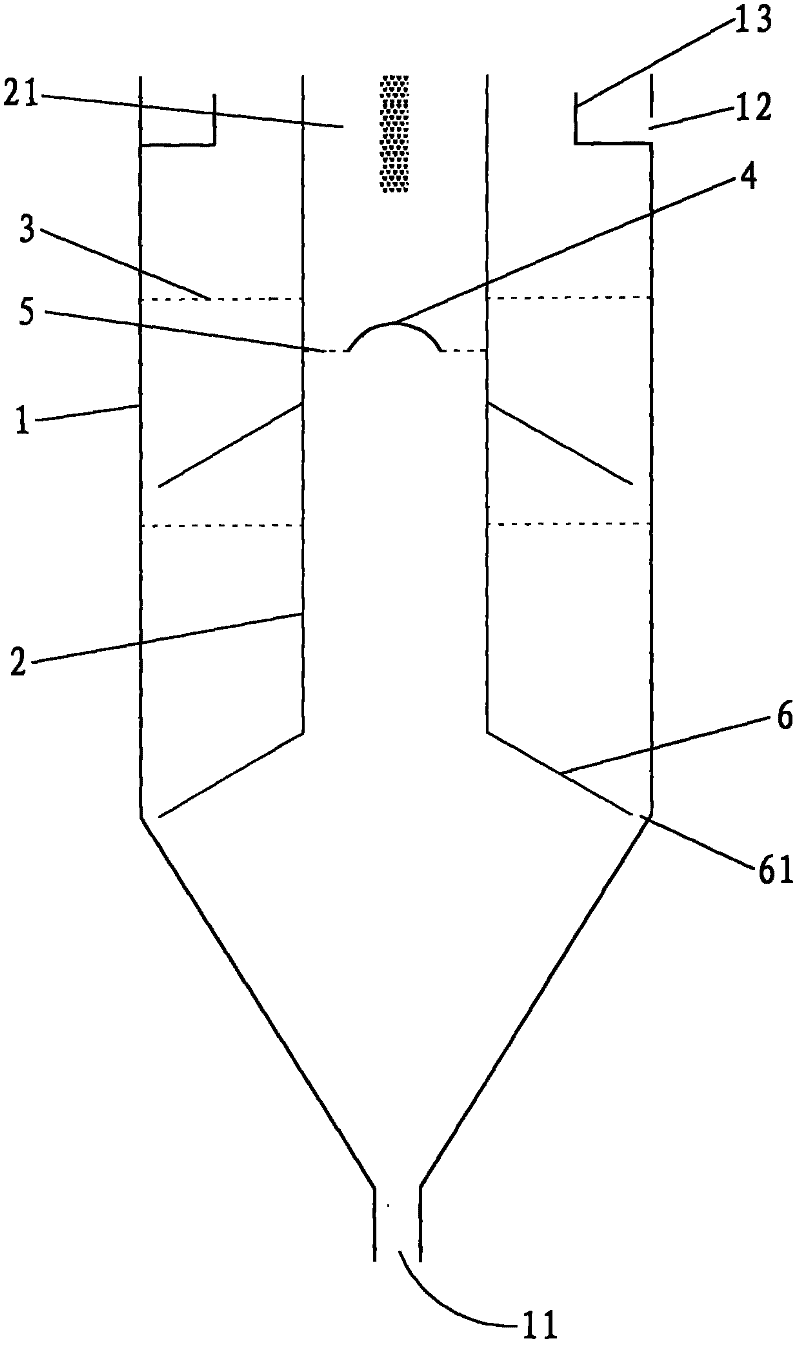

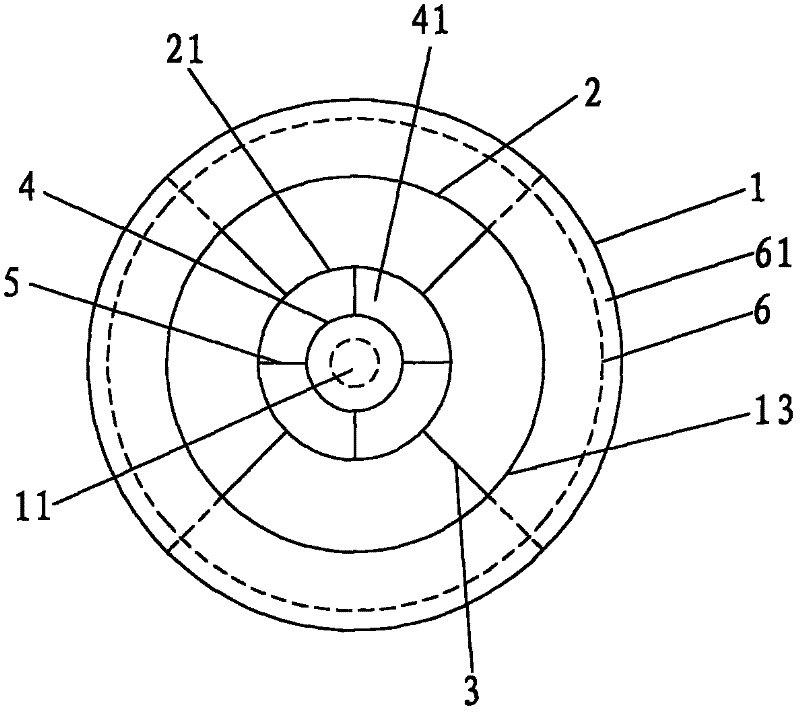

[0034] Such as Figure 1 to Figure 3 As shown, a tailings sewage rapid sedimentation concentration tank disclosed by the present invention includes an outer cylinder 1 and an inner cylinder 2 .

[0035] The inner cylinder 2 is nested in the outer cylinder 1 by means of the support frame 3, which can be composed of several connecting rods to ensure the support and fixation effect without reducing the static clean water area and ensure the treatment effect. The upper end of the inner cylinder 2 is a sewage inlet 21 . A buffer baffle 4 is installed in the middle of the inner cylinder 2 by means of a support frame 5. There is a feeding gap 41 between the edge of the buffer baffle 4 and the inner wall of the inner cylinder 2. The support frame 5 can also be composed of several connecting rods to ensure the support The effect is fixed but the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com