Integrated reactor and method for removing ammonia nitrogen in drinking water

A reactor and drinking water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of easy penetration of powdered activated carbon, complicated management, physical damage of membrane surface, etc. problems, to achieve the effect of low operating cost, convenient operation and management, and small head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

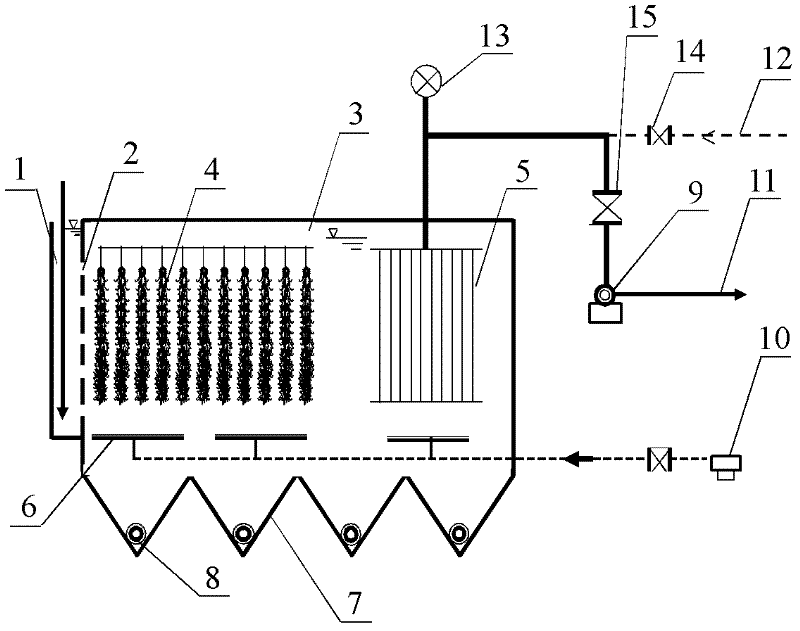

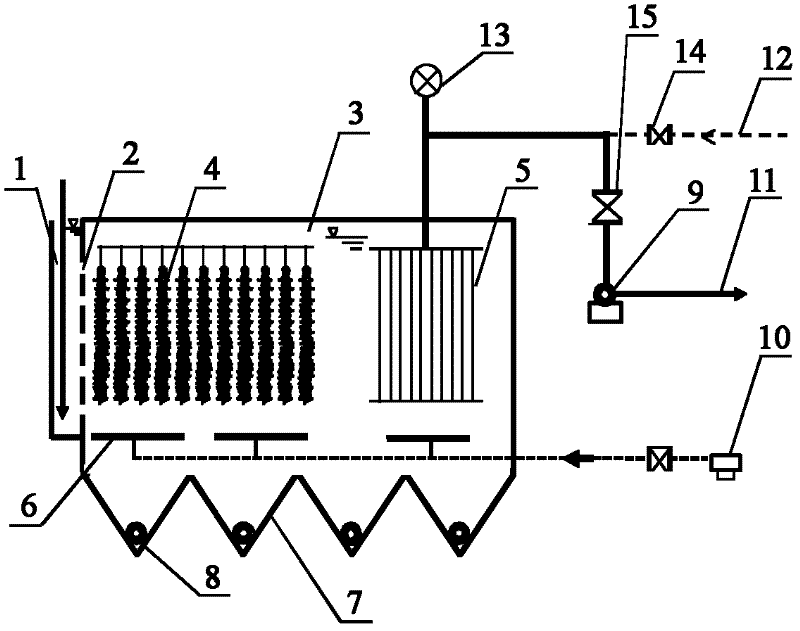

[0052] See figure 1 The integrated reactor for removing ammonia nitrogen in drinking water that realizes microbial nitrification and ultrafiltration separation process includes a biological nitrification zone unit and an ultrafiltration membrane filtration zone unit; the biological nitrification zone unit and the ultrafiltration membrane filtration The zone units are set in the same reaction pool.

[0053] The biological nitrification zone unit includes a biological filler 4 for microbial film formation, an aeration device 6 and a sludge tank 7 .

[0054] A perforated plate 2 is installed in the reaction pool, and the top of the space formed between one side of the perforated plate 2 and the wall of the reaction pool is set as an opening; on the other side of the perforated plate 2 A bracket filled with the biological filler 4 is installed on the side, an aeration device 6 and a sludge tank 7 are installed under the biological filler 4, and a sludge discharge pipe 8 is instal...

Embodiment 2

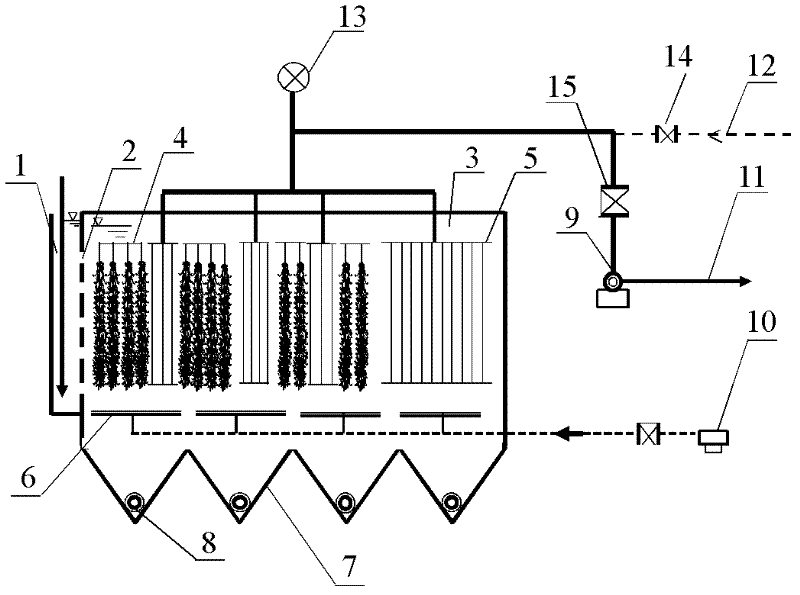

[0066] See figure 2 , the design and establishment of an integrated reactor for the removal of ammonia nitrogen in drinking water for the realization of microbial nitrification and ultrafiltration separation processes basically as in Example 1, except that the support and ultrafiltration membrane assembly filled with the biological filler are respectively four.

[0067] The installation method of the support filled with the biological filler and the ultrafiltration membrane module is to adopt the installation method of interlacing and mixing with each other, and adjacent to the perforated plate 2 is the bracket filled with the biological filler. stand.

[0068] The method for removing ammonia nitrogen in drinking water by using the above-mentioned integrated reactor is as follows: after the water to be treated enters the steady flow area 1 of the integrated reactor from the water inlet, the water enters the reaction area 3 evenly through the perforated plate 2, and then flow...

Embodiment 3

[0073] See figure 1 The integrated reactor for removing ammonia nitrogen in drinking water that realizes microbial nitrification and ultrafiltration separation process includes a biological nitrification zone unit and an ultrafiltration membrane filtration zone unit; the biological nitrification zone unit and the ultrafiltration membrane filtration The zone units are set in the same reaction pool.

[0074] The biological nitrification zone unit includes a biological filler 4 for microbial film formation, an aeration device 6 and a sludge tank 7 .

[0075]A perforated plate 2 is installed in the reaction pool, and the top of the space formed between one side of the perforated plate 2 and the wall of the reaction pool is set as an opening; on the other side of the perforated plate 2 A bracket filled with the biological filler 4 is installed on the side, an aeration device 6 and a sludge tank 7 are installed under the biological filler 4, and a sludge discharge pipe 8 is install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture range | aaaaa | aaaaa |

| Membrane flux | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com