Marine Thrust Bearing Resonant Converter

A thrust bearing and converter technology, applied in the directions of bearings, shafts, bearings, bearing components, etc., can solve the problems of convenient disassembly and flexible adjustment, improper design, difficulty in controlling longitudinal stiffness and damping of shafting, etc., to achieve reasonable control. , the effect of reducing the longitudinal vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further defined below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as figure 1 Shown is a marine thrust bearing resonant converter of the present invention, which consists of an improved thrust bearing 1 and a resonant converter 2 .

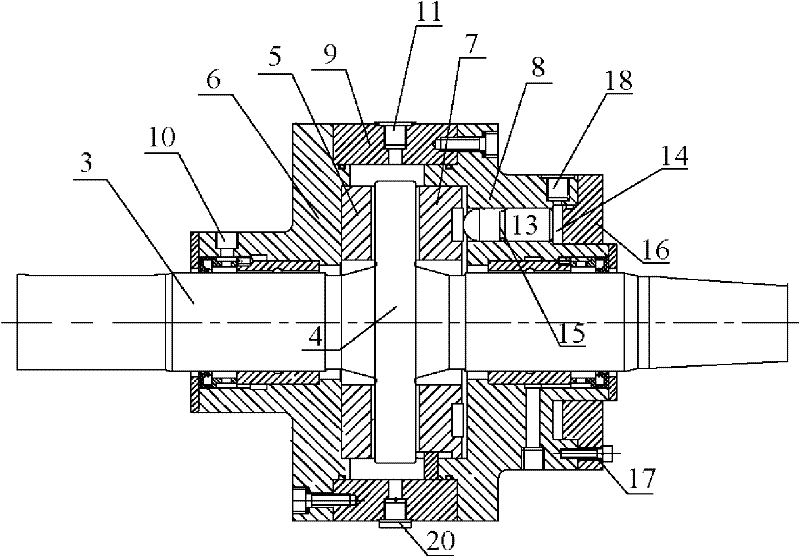

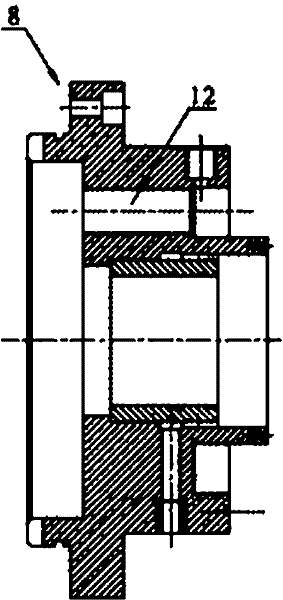

[0030] As shown in Figure 2(a), the main components of the improved thrust bearing 1 include a thrust shaft 3, a thrust ring 4, a rear thrust block 5, a rear end cover 6, a front thrust block 7, a front end cover 8 and a bearing housing 9. In order to ensure the safe operation of the thrust bearing during the rotation of the shaft system and to form an oil film between the thrust block and the thrust ring, the oil inlet 10 and the oil outlet 11 at the rear end of the thrust bearing lubricating oil are respectively set to meet the internal circulation of the thrust bearing to supply lubricating oil .

[0031] Compared with the structure of the traditional marine thrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com