No-tillage rotation method of flue-cured tobacco and grass

A technology for flue-cured tobacco and forage, applied in the fields of botanical equipment and methods, sowing, horticulture, etc., can solve the problems of limited dosage, aggravated flue-cured tobacco disease, affecting the yield and quality of tobacco leaves, and achieves simple operation, improved crop rotation efficiency, and improved tobacco leaf yield. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

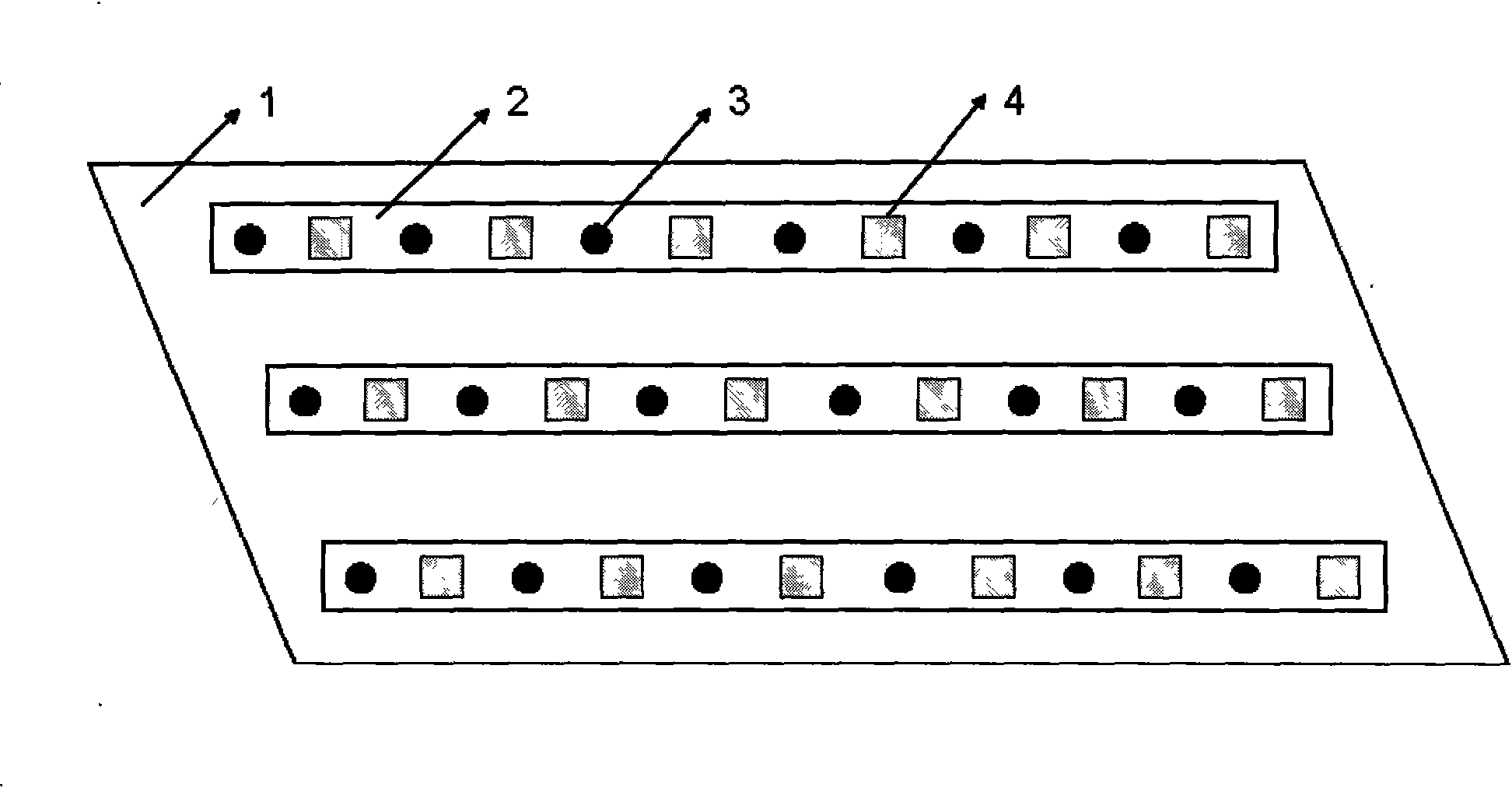

[0020] In a flue-cured tobacco cultivation site, a no-tillage rotation of high-quality forage grass Huangzhu grass and flue-cured tobacco was carried out.

[0021] When cultivating flue-cured tobacco in the first year, ridges should be raised. The height of the ridge is 0.25m, the distance between the ridges is 1.0m, and the distance between the plants of the cultivated flue-cured tobacco is 0.55m. , to protect the ridge body; after the spring of the next year, clear the tobacco stems and weeds out of the tobacco field, and then plant imperial bamboo grass. The planting density of imperial bamboo grass is the same as that of flue-cured tobacco. After the bamboo grass is harvested, the stubble remains in the ridge body, and the ridge body should be protected; in the third year, after the beginning of spring and before tobacco planting, apply a wettable powder herbicide of napropamide with a mass fraction of 50%, every 667m 2 Apply 150g to control the growth of weeds. When plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com