A double-layer electric heating container

An electric heating and container technology, which is applied in the direction of boiling water utensils, shells/sleeves of cooking appliances, etc., can solve the problems of unsatisfactory thermal insulation effect, unsatisfactory thermal insulation effect, easy burns to users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

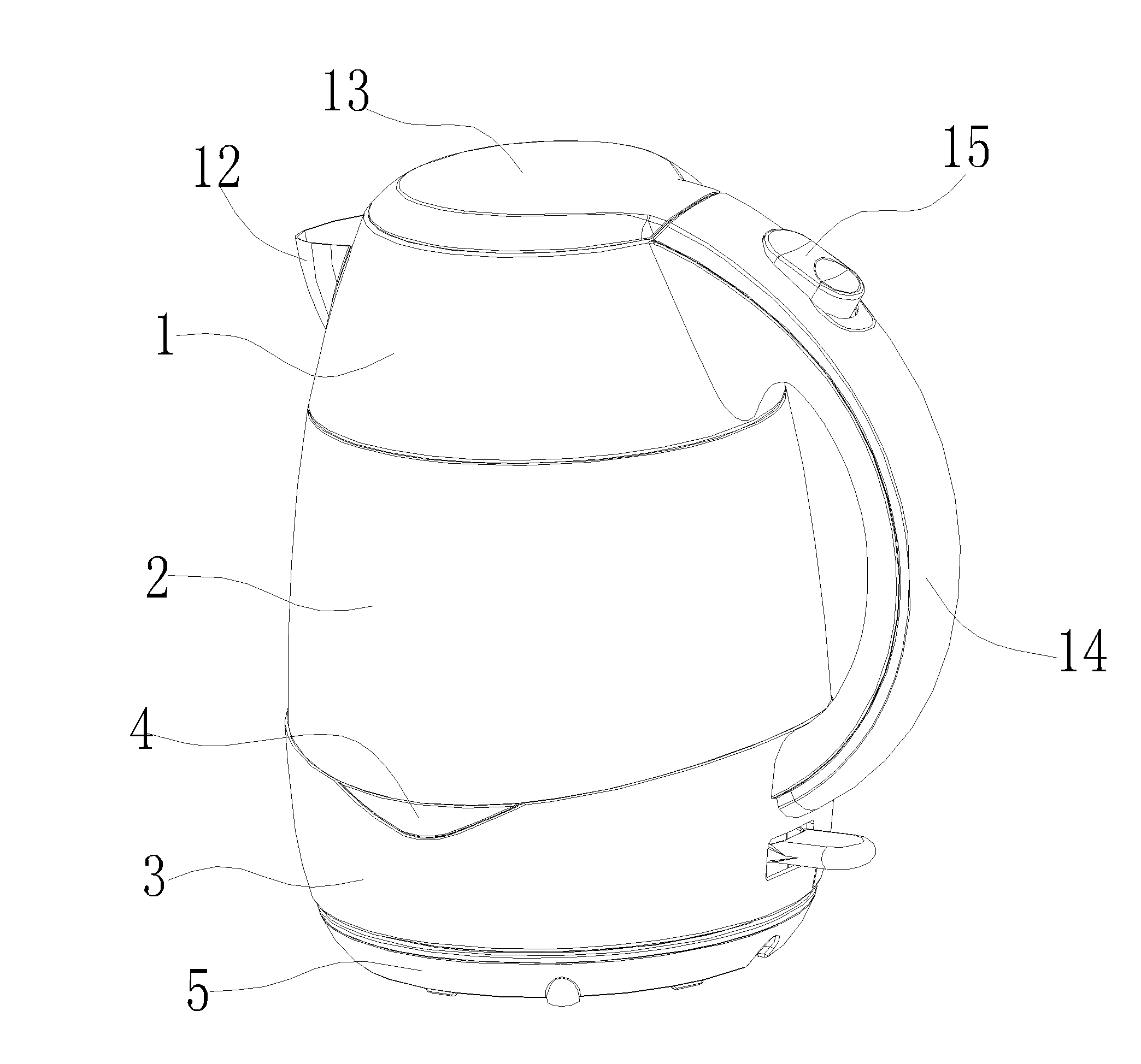

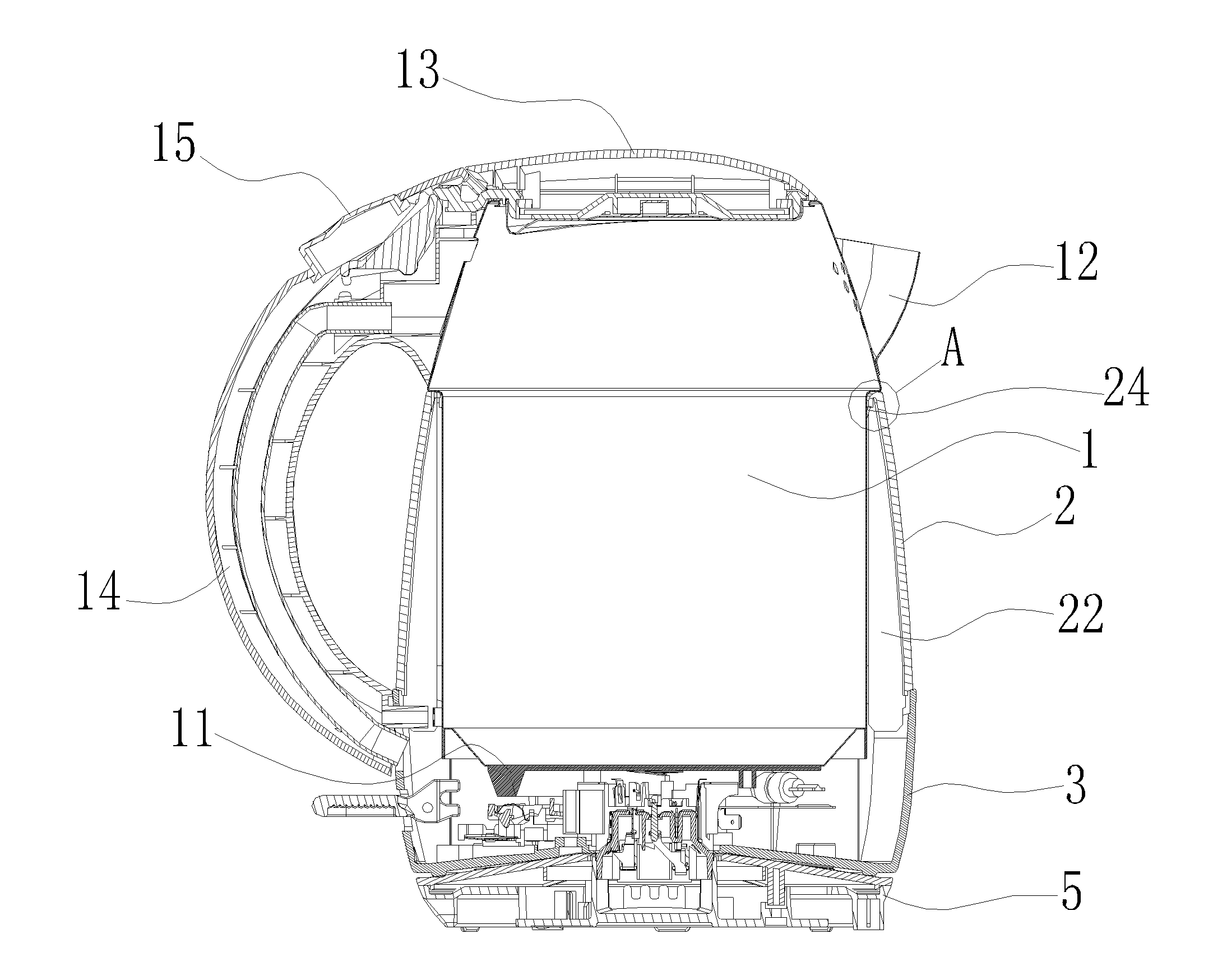

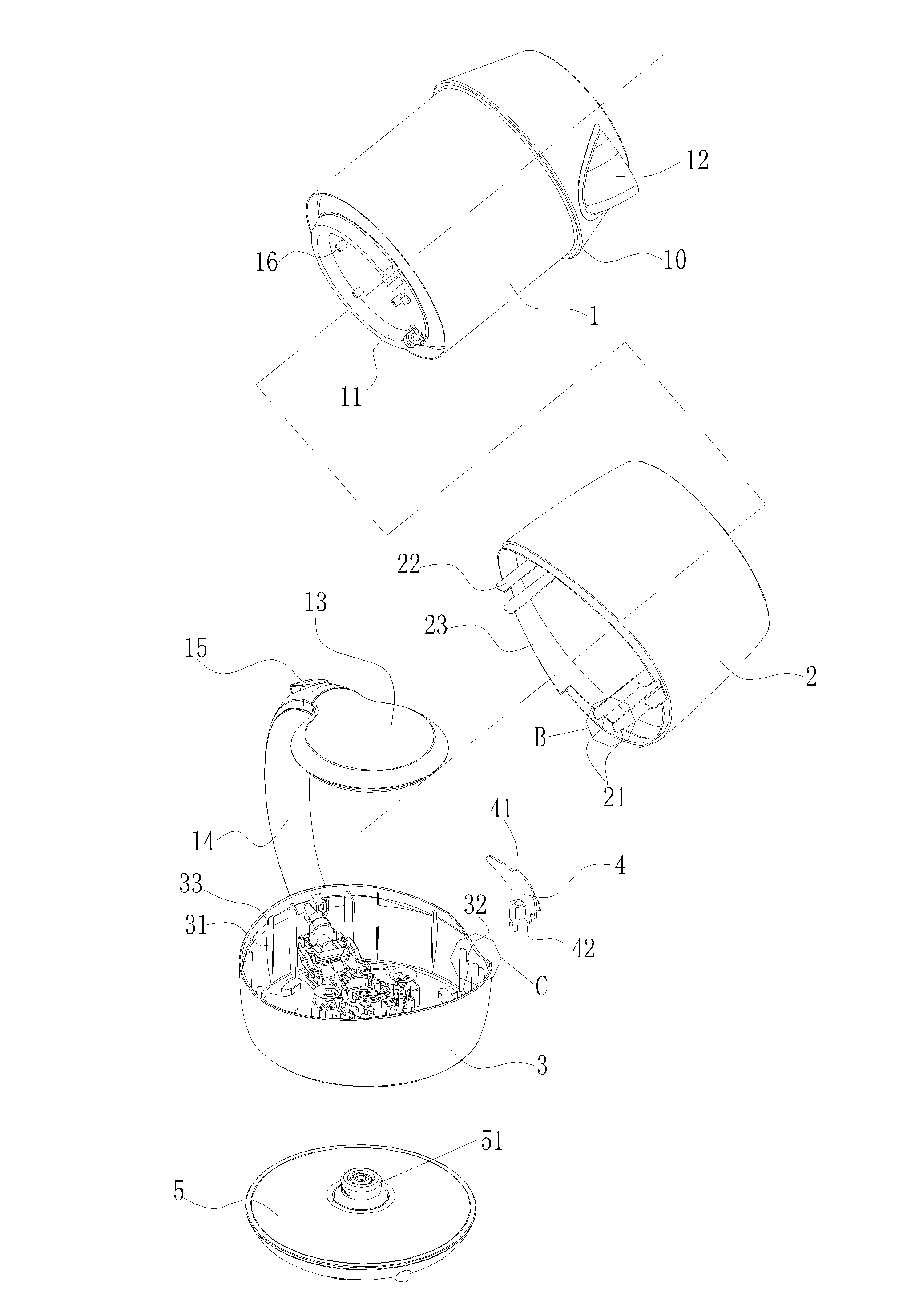

[0023] Such as Figure 1 to Figure 7 As shown, a double-layer electric heating container, especially a double-layer electric kettle, includes a stainless steel water storage container 1, an electric heating element 11 arranged at the bottom of the water storage container 1, and a spout arranged on the water storage container 1 12. The pot cover 13 and the pot handle 14, the outer shell 2 covered outside the water storage container 1, the base 3 connected with the outer shell 2 and the bottom of the water storage container 1, the base 3 is provided with a heating The control circuit electrically connected to the element 11, the power switch 15 electrically connected to the control circuit, and the socket electrically connected to the heating element 11 and the control circuit, wherein the outer casing 2 and the base 3 are made of plastic materials. The middle and upper portion of the side wall of the water storage container 1 is provided with a raised portion 10 outward in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com