A kind of processing technology of traditional Chinese medicine emblica

A processing technology and a technology of Emblica Radix are applied in the processing technology field of traditional Chinese medicine Emblica Radix, can solve problems such as being difficult to store and utilize, easy to be moldy and moth-eaten, reduce effective ingredients, etc. The effect of good practical value and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Use Shenyang JDF-0.2 type vacuum freeze dryer to process traditional Chinese medicine Amla emblica.

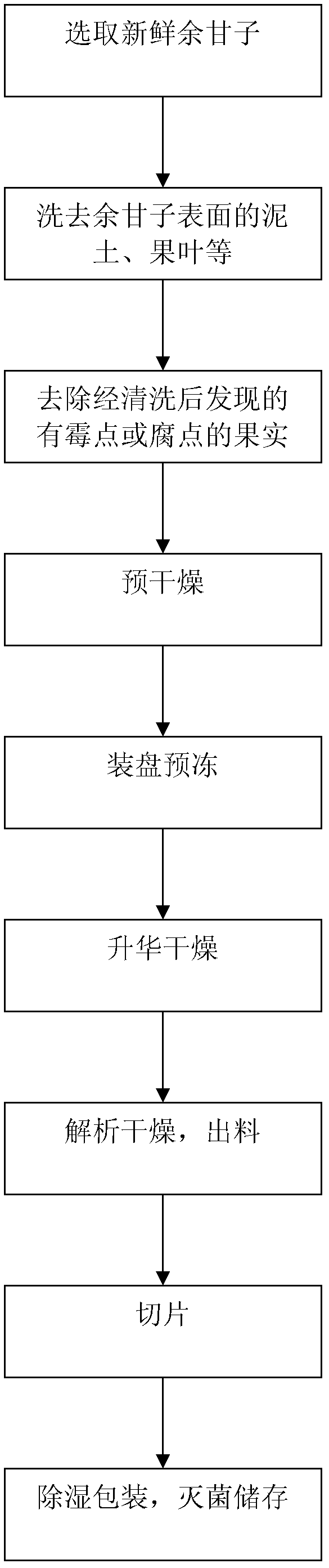

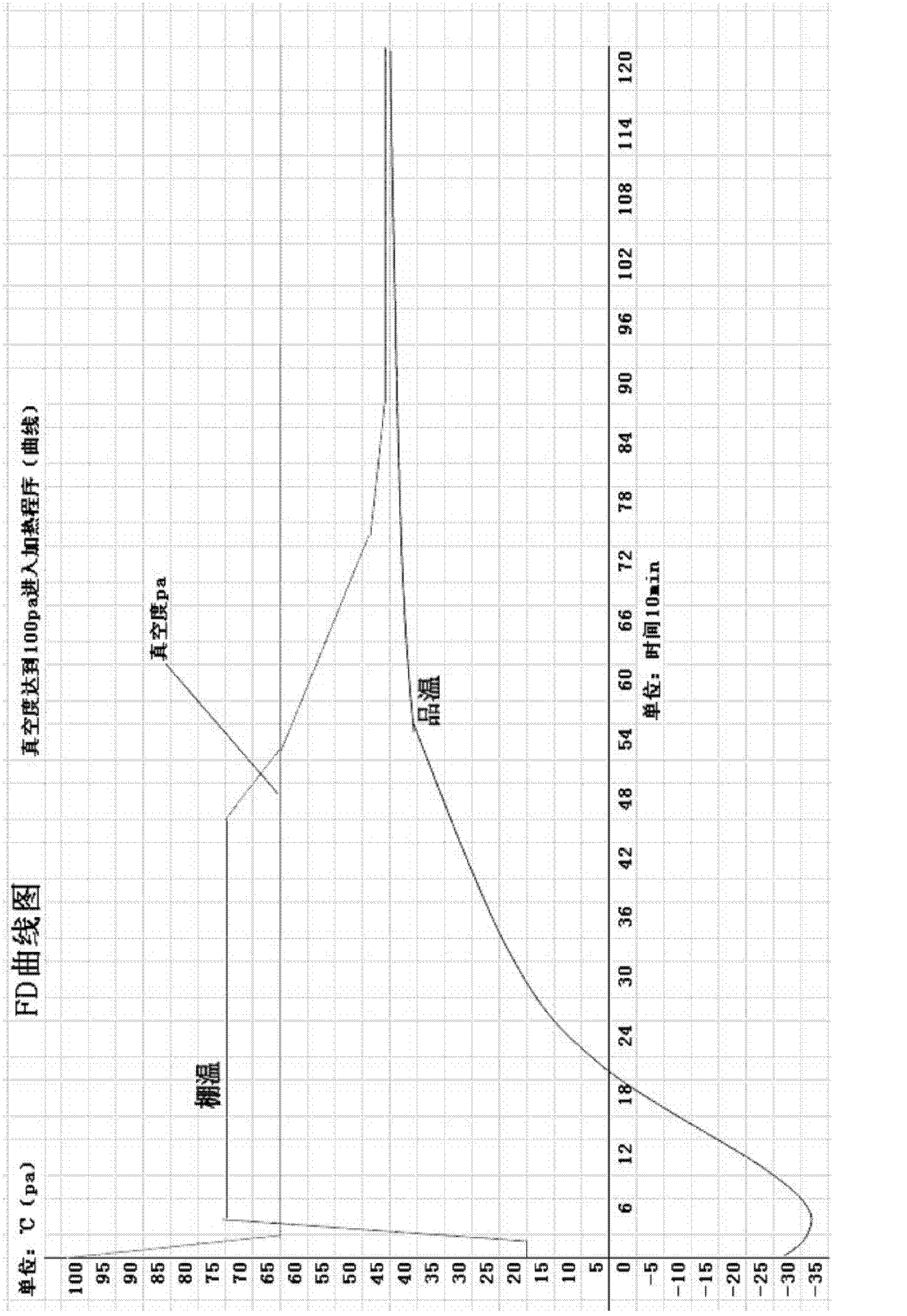

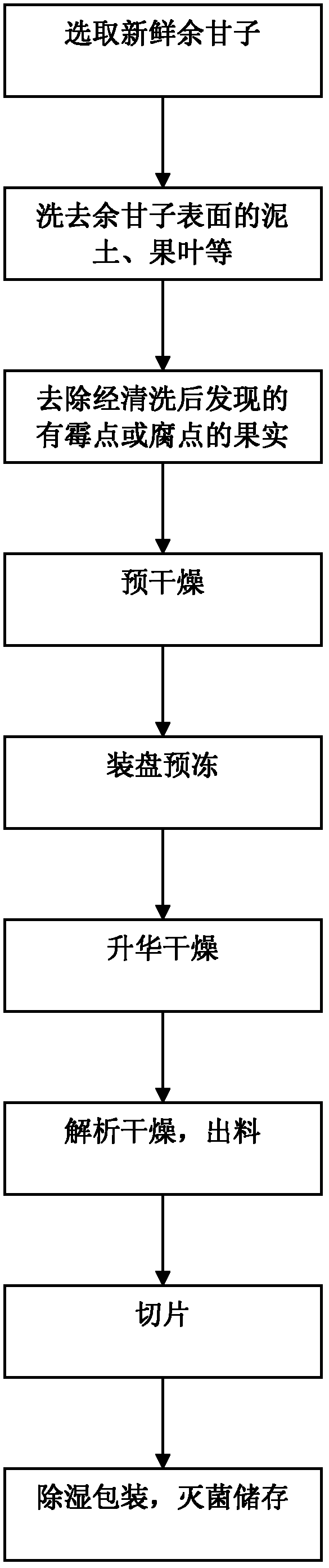

[0038] see figure 1 , select fresh, non-rotten, non-mildew, and moderately mature emblica raw materials, rinse them with running water, wash off the soil, fruit leaves, etc. on the surface of the emblica wild fruit, and drain them; The found fruit of emblica with mildew or rotten spots; pre-dry the emblica to a water content of 80% and then pack it into a tray. Freeze; then vacuumize the system until the absolute pressure of the system is 65Pa, start heating to 40°C-55°C, sublimate and dry for 18 hours; then keep the material temperature at 35°C, and discharge the material after the water content reaches below 2%. Sliced in a constant temperature dehumidification workshop, sterilized after dehumidification packaging to make emblica decoction pieces, which can be stored for a long time.

Embodiment 2

[0040] Vacuum freeze-drying of Amla emblica was carried out by using Shenyang JDF-0.2 vacuum freeze-dryer.

[0041] Select fresh, non-rotten, non-mildew, and moderately mature emblica raw materials, rinse with running water to remove the soil, fruit leaves, etc. on the surface of the emblica wild fruit, and drain; after cleaning, re-screen to remove The emblica fruit with moldy or rotten spots; pre-dry the emblica fruit to a water content of 80%, then pack it into a tray with a weight of 10kg / m2 and a thickness of 2cm, and then pre-freeze it at -40°C after gradually cooling down for 2 hours; Then vacuumize the system until the absolute pressure of the system is 70Pa, start heating to 50°C-60°C, sublimate and dry for 20 hours; then keep the material temperature at 40°C, and discharge the material after the water content reaches below 2%.

[0042] The dried emblica can be made into Chinese herbal decoction pieces according to the method of Example 1, and can also be combined wit...

Embodiment 3

[0044] Use Shenyang JDF-0.2 type vacuum freeze dryer to process traditional Chinese medicine Amla emblica.

[0045] Select fresh, non-rotten, non-mildew, and moderately mature emblica raw materials, rinse with running water to remove the soil, fruit leaves, etc. on the surface of the emblica wild fruit, and drain; after cleaning, re-screen to remove The emblica fruit with moldy or rotten spots; pre-dry the emblica fruit to a water content of 70%, then pack it into a tray with a weight of 10kg / m2 and a thickness of 2cm, and pre-freeze it at -50°C after gradually cooling down for 3 hours; Then vacuumize the system until the absolute pressure of the system is 70Pa, start heating to 55°C-60°C, sublimate and dry for 22 hours; then keep the temperature of the material at 45°C, and discharge the material after the water content reaches below 2%.

[0046] The dried emblica can be made into Chinese herbal decoction pieces according to the method of Example 1, and can also be combined w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com