Septic tank object hardening processor

A processor and septic tank technology, applied in dewatering/drying/concentrating sludge treatment, centrifuges, chemical instruments and methods, etc., can solve the problems of increasing vehicle exhaust emissions, low work efficiency, and high energy consumption, achieving Reduce fuel consumption, low cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

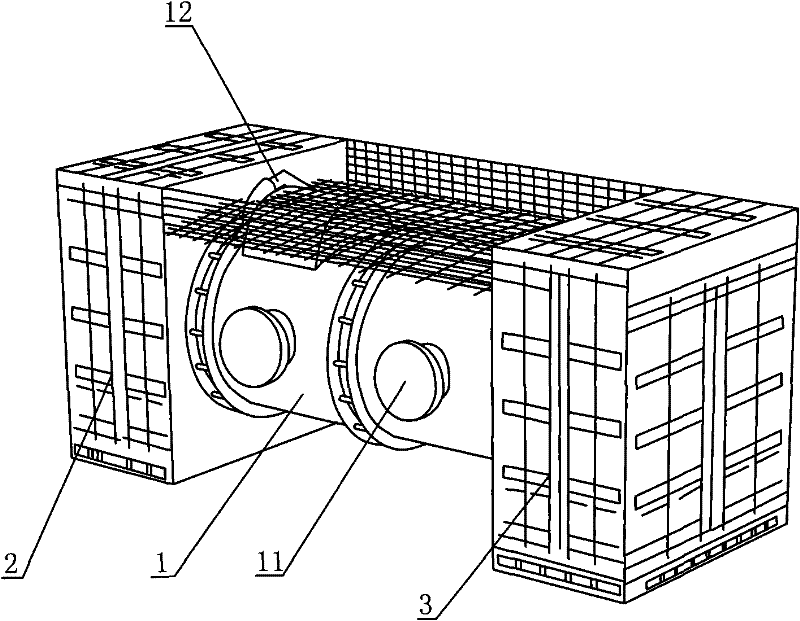

[0036] Such as figure 1 As shown, this embodiment discloses a preferred structure of a septic tank object hardening treatment machine, which includes a normally closed sewage treatment tank 1, a power box 2 arranged on one side of the sewage treatment tank 1, and a set The dirt collection box 3 on the other side of the dirt treatment tank 1 is provided with a water outlet 11 under the side of the dirt treatment tank 1 and a sewage inlet 12 at the top of the dirt treatment tank 1 . Wherein, the power box 2 is used for installing power equipment, and the power equipment includes motors, driving motors, vacuum pumps and switch box vacuum pumps, etc., which are all mature products, not marked one by one in the figure, and the vacuum pump is connected to the filter bucket through pipelines to remove the sewage mixture. Pumped into the waste disposal tank.

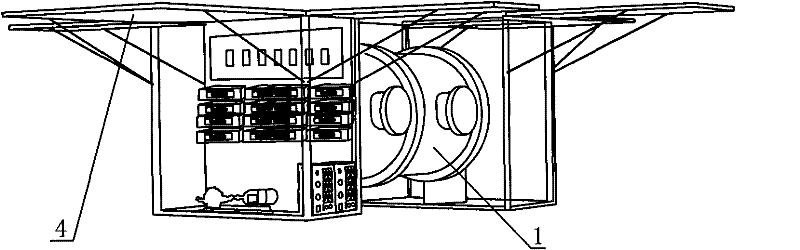

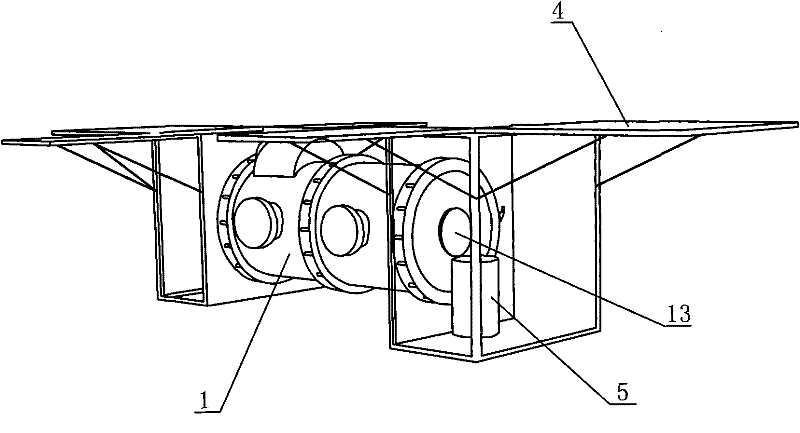

[0037] Such as figure 2 , 3 As shown, the three outward side walls 4 of the power box 2 and the dirt collection box 3 are ...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] 1. A high-pressure water pump (not shown) is also installed next to the sewage treatment tank, and a high-pressure nozzle (not shown) for dredging the pipeline is connected to the water outlet of the high-pressure water pump through a high-pressure rubber hose. Water pumps and high-pressure nozzles are mature products, and their installation locations can also be installed in different places according to actual requirements. The installation should follow the principles of small footprint and convenient operation and maintenance. Because, the current urban sewage treatment process is often accompanied by some blockages. At this time, the high-pressure water pump can be turned on for dredging, which is equivalent to integrating the dredging vehicle into one.

[0045] 2. The water outlet of the high-pressure water pump is also connected to the filter barrel through a high-pressure hose, such as Figure...

Embodiment 3

[0047]The difference between this embodiment and embodiment 2 is that a backup power device is also arranged beside the sewage treatment tank, and the backup power device is a power diesel generator (not shown), which is a mature product. After the generator is added in this embodiment, it can be used in a wider range, and it can also be used in places where there is no three-phase AC power supply.

[0048] The present invention can also be further improved, and the power box, the dirt treatment tank, and the dirt collection box are made into three independent parts, and the three parts are combined horizontally during use, and the independent parts are convenient to disassemble. For the convenience of moving, rollers are arranged under the power box and the dirt treatment tank.

[0049] The present invention can also be further improved, and the dirt treatment tank, the power box, and the dirt collection box are all arranged on the motor vehicle, so that the engine of the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com