A drilling and tapping integrated composite tap

A composite wire and integrated technology, applied in the field of tool manufacturing, can solve the problems of frequent replacement of drill bits and taps, difficulty in ensuring the coaxiality of drill bits and taps, and affecting product quality, so as to save the time for clamping and tool changing and shorten the production line , The effect of shortening the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

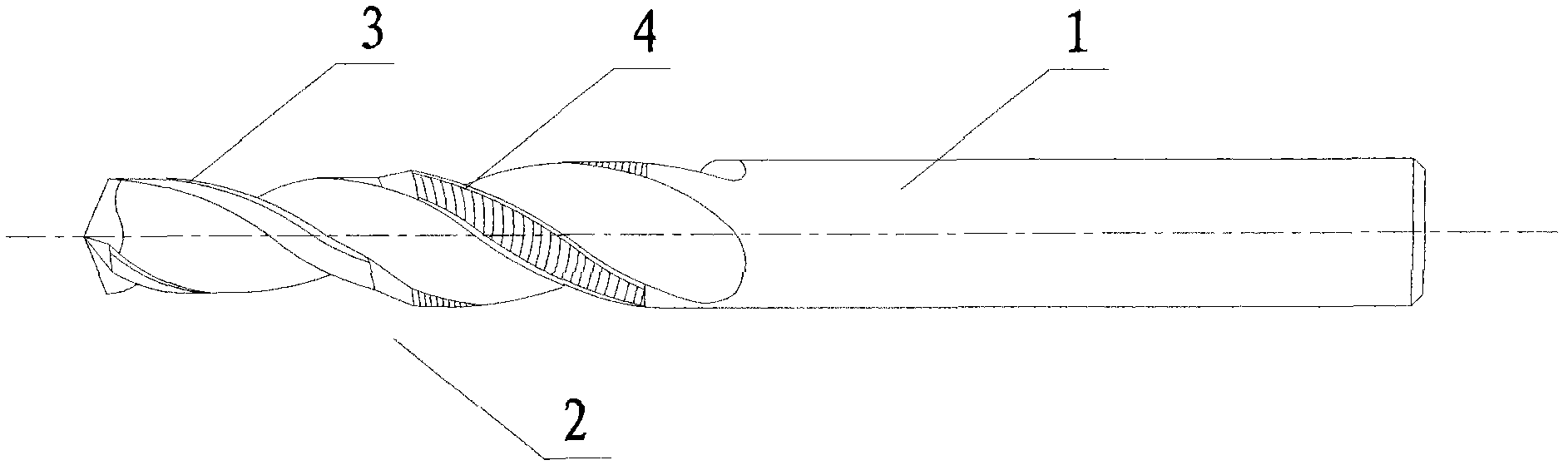

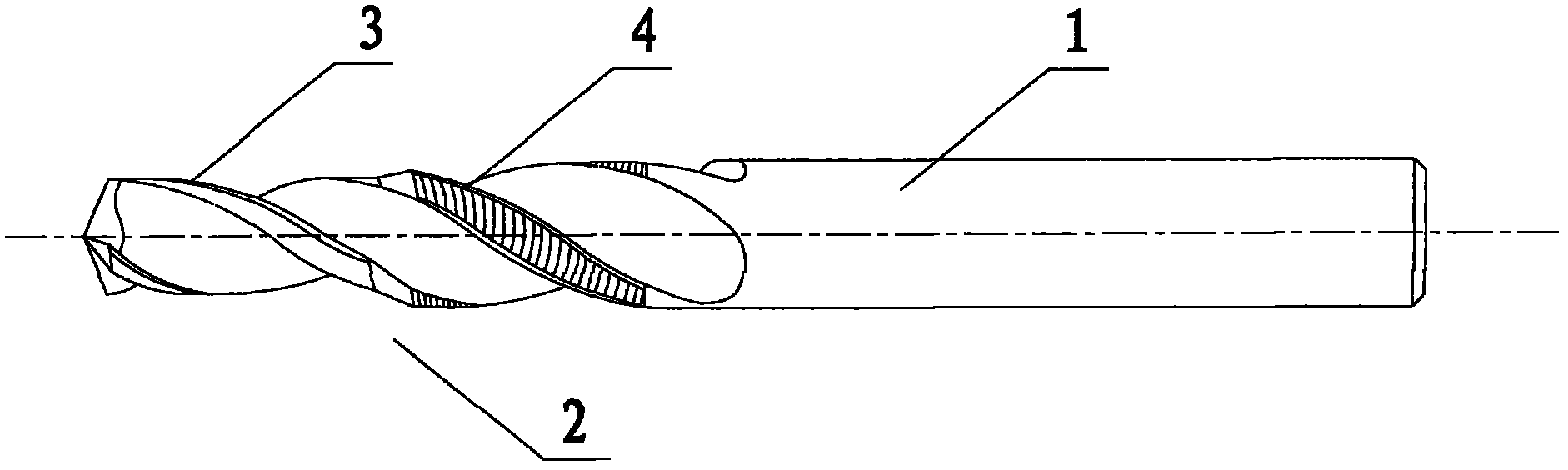

[0012] Such as figure 1 As shown, the drilling and tapping integrated tap of this embodiment includes a shank 1 and a blade 2, the blade 2 is composed of a drill 3 at the end and a tap 4 close to the shank, and the drill 3 and the tap 4 are formed by the blade 2 along the It is formed by the same helical groove arranged in the axial direction.

[0013] The blade part 2 of the compound tap adopts the combination form of the drill bit 3 and the tap 4. After drilling, the tapping thread can be realized without changing the tool, and the scattered processes are reasonably concentrated, the number of processes is shortened, the process is simplified, and the clamping is omitted. Tool change time reduces the number of special machine tools and special fixtures, shortens the production line, simplifies equipment design, and improves production efficiency; moreover, the integrated drilling and tapping structure also ensures the machining accuracy and product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com