A municipal product production line

A production line and product technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of high labor intensity, rough products, and small labor, and achieve small labor, high labor intensity, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

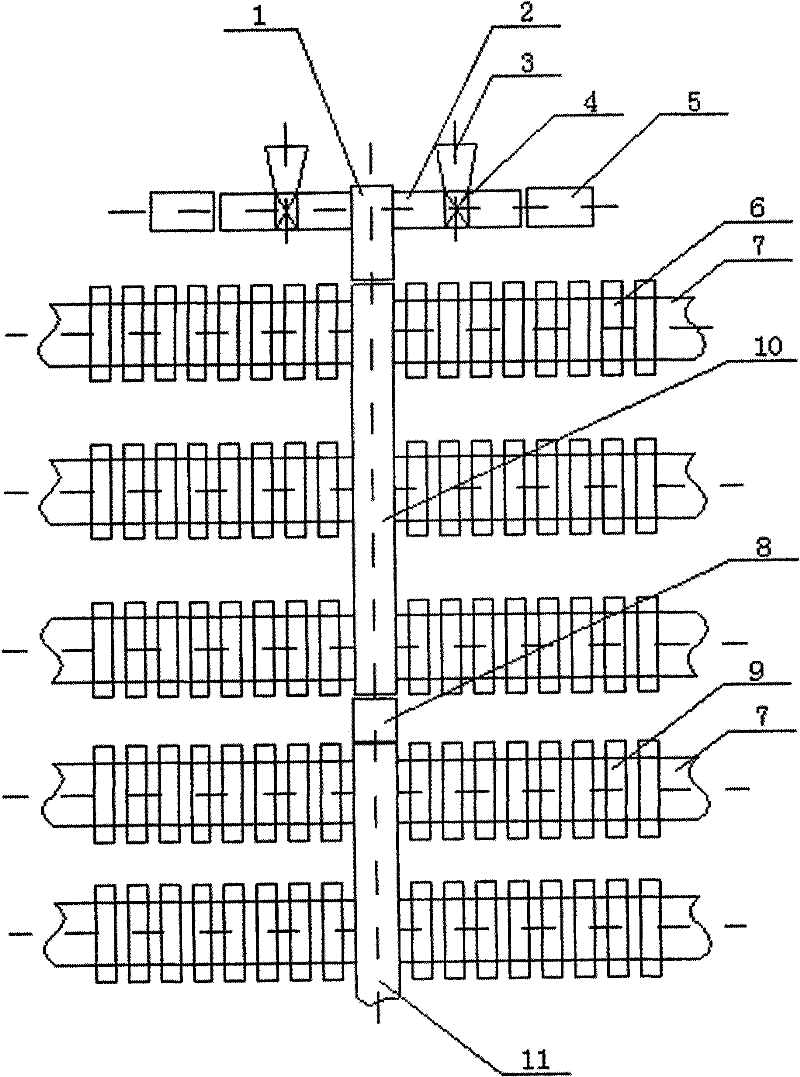

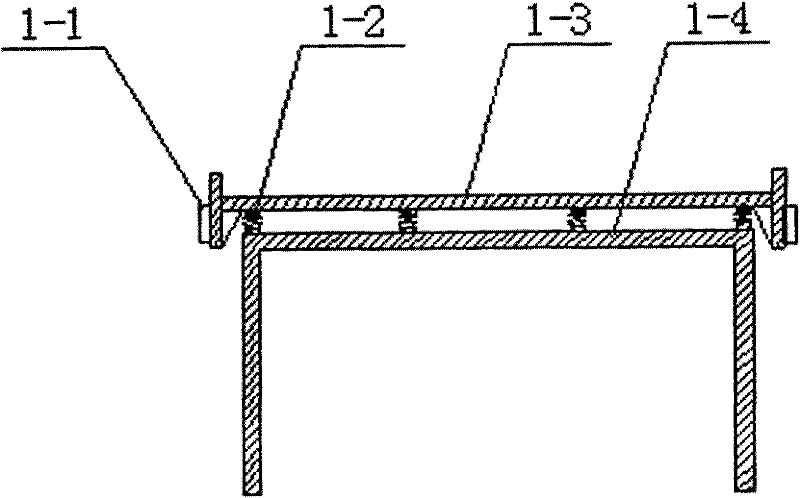

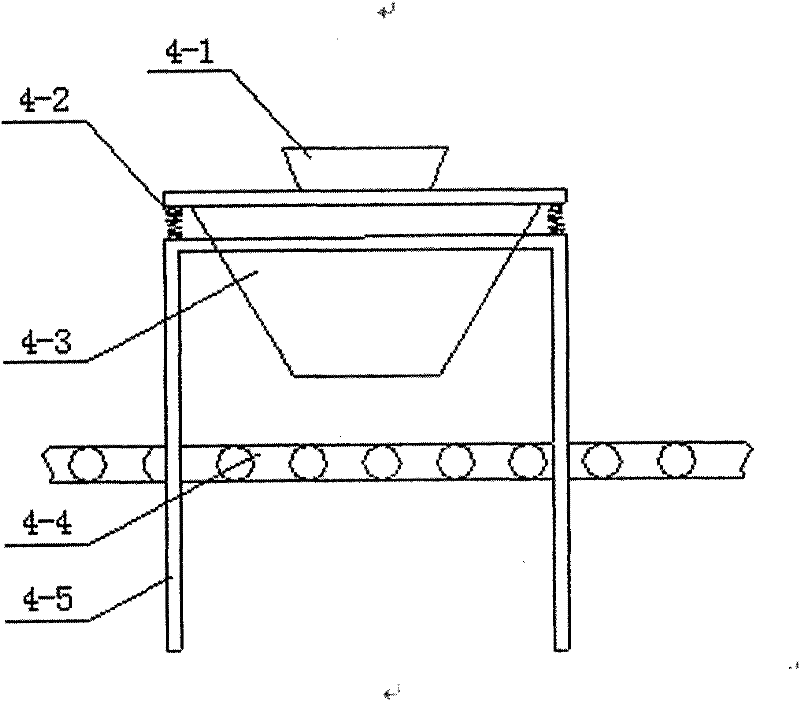

[0015] Specific embodiment one: reference figure 1 , This specific embodiment adopts the following technical solutions: it consists of the first vibration conveying device 1, the first belt conveyor 2, the horizontal mixer 3, the blanking device 4, the second vibration conveying device 5, the maintenance pallet car 6, The runway 7, the demolding device 8, the finished product pallet car 9, the second belt conveyor 10, and the third belt conveyor 11 are composed of a first belt conveyor 2 horizontally arranged on both sides of the first vibrating conveyor device 1, and the first belt Two horizontal mixers 3 are provided on one side of the conveyor 2, and the lower end of the horizontal mixer 3 is provided with a feeding device 4, which is provided at the upper end of the first belt conveyor 2, and the first belt conveyor 2 is provided at both ends There is a second vibrating conveying device 5, the end of the first vibrating conveying device 1 is longitudinally provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com