Retarder used in the preparation of sulfoaluminate cement quick-hardening concrete

A technology of sulphoaluminate cement and strong sulphoaluminate, which is applied in the field of special retarders, and can solve problems such as poor bonding of old concrete, traffic jams, and concrete cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

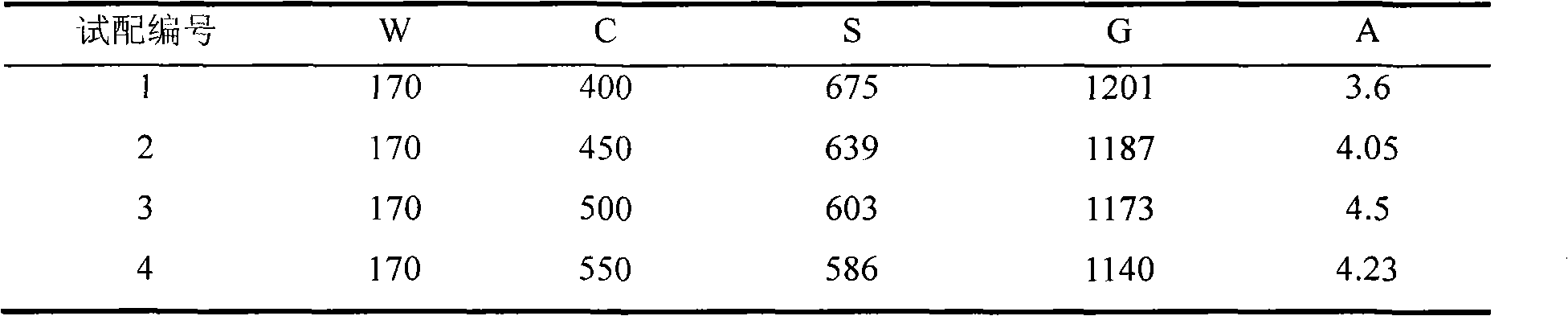

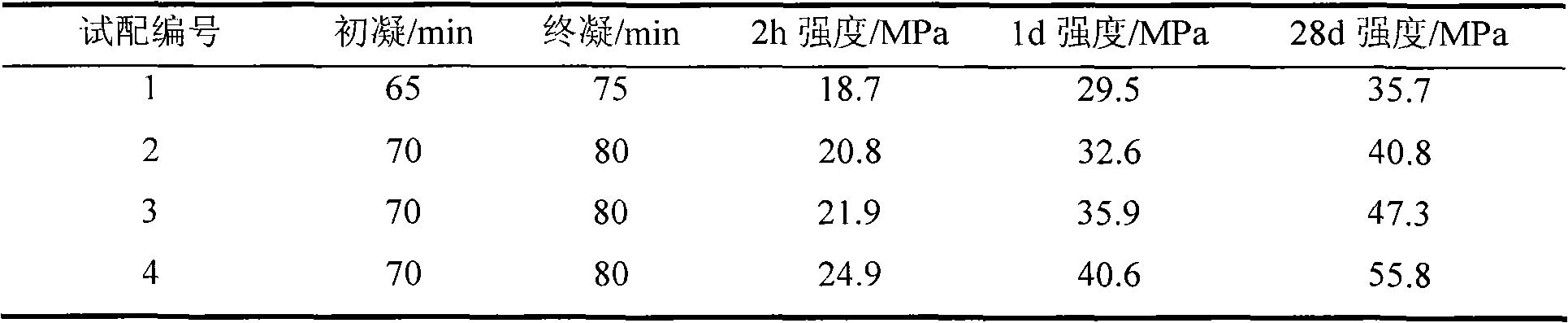

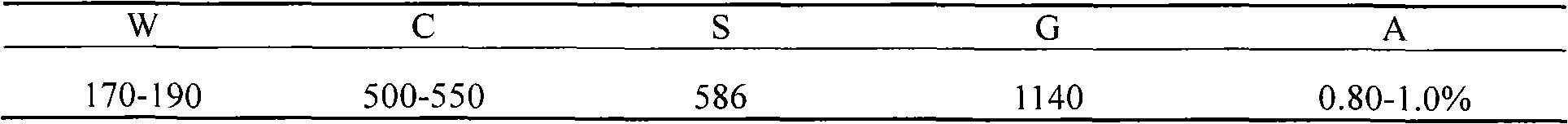

Examples

Embodiment Construction

[0023] First of all, the present invention combines the basic requirements of the actual emergency repair project, aiming at the sulphoaluminate cement quick-hardening concrete adopting the segmental control technology, the specific requirements for determining its performance index are as follows:

[0024] 1) Rapid hardening concrete is required to have good fluidity within at least 1.5 hours (in this article, "h" refers to "hour", the same below) considering factors such as transportation distance, traffic jams and on-site waiting for fast-hardening concrete from the machine to the site. ;

[0025] 2) After the concrete arrives at the site, after adding the early strength agent, the concrete is required to maintain construction operability for at least 30 minutes, and the ideal construction operation time is 30-50 minutes (in this article, "min" means "minute", the same below);

[0026] 3) After the concrete arrives at the site and the early strength agent is added, the init...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com