A kind of low odor polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of low-odor polypropylene composite materials, can solve problems such as use restrictions, and achieve the effects of low organic volatile content, simple preparation process, and excellent thermo-oxidative stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

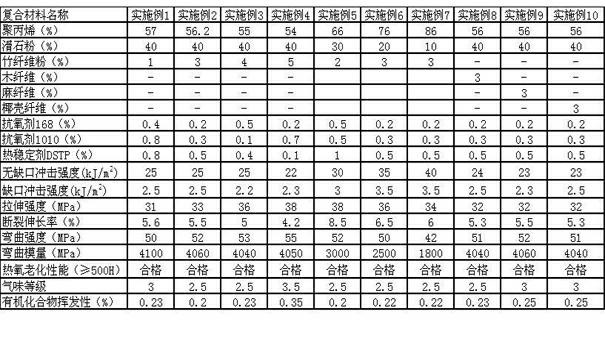

Examples

Embodiment 1

[0040] Weigh 57% of polypropylene, 40% of talcum powder, 1% of bamboo fiber, 0.8% of heat stabilizer DSTP, 0.8% of antioxidant 1010, and 0.4% of antioxidant 168 in a high-speed mixer by weighing 3- After 5 minutes, melt and extrude in a twin-screw extruder and granulate to obtain the polypropylene composite material of the present invention. The process control conditions are: 180-190°C in the first zone, 200-210°C in the second zone , 200~210℃ in the third zone, 210~215℃ in the fourth zone, 210~215℃ in the fifth zone, 210~215℃ in the sixth zone, 215~225℃ in the seventh zone, 215~225℃ in the eighth zone, 215~225℃ in the ninth zone, The tenth zone is 215~225℃; the residence time is 1-2 minutes, and the pressure is 12-18MPa.

Embodiment 2

[0042] Take 56% polypropylene, 40% talcum powder, 3% bamboo fiber, 0.5% heat stabilizer DSTP, 0.3% antioxidant 1010, and 0.2% antioxidant 168 in a high-speed mixer for 3-5 minutes by weight , and then melted and extruded in a twin-screw extruder and pelletized to obtain the polypropylene composite material of the present invention. Zone 200~210℃, Zone 4 210~215℃, Zone 5 210~215℃, Zone 6 210~215℃, Zone 7 215~225℃, Zone 8 215~225℃, Zone 9 215~225℃, Zone 10 215~225℃; the residence time is 1-2 minutes, and the pressure is 12-18MPa.

Embodiment 3

[0044] Take 55% polypropylene, 40% talcum powder, 4% bamboo fiber, 0.4% heat stabilizer DSTP, 0.1% antioxidant 1010, 0.5% antioxidant 168 and dry mix in a high-speed mixer for 3-5 minutes by weight , and then melted and extruded in a twin-screw extruder and pelletized to obtain the polypropylene composite material of the present invention. Zone 200~210℃, Zone 4 210~215℃, Zone 5 210~215℃, Zone 6 210~215℃, Zone 7 215~225℃, Zone 8 215~225℃, Zone 9 215~225℃, Zone 10 215~225℃; the residence time is 1-2 minutes, and the pressure is 12-18MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com