Sponge cadmium cake smelting automatic feeding machine

An automatic feeding machine, sponge cadmium cake technology, applied in lighting and heating equipment, furnace, electric charge control and other directions, can solve the problems of harm to workers' physical and mental health, low production efficiency, high labor intensity of workers, etc., to increase convenience and transportation. Quantity, low manufacturing cost, and the effect of protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

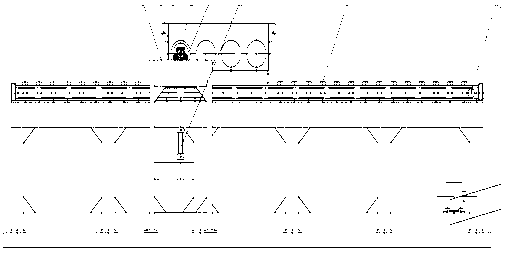

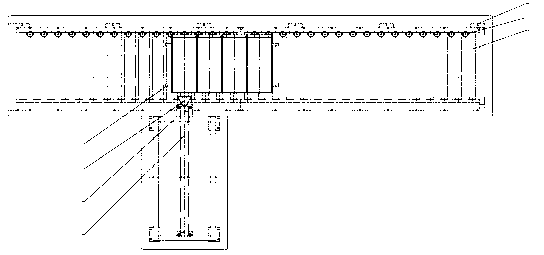

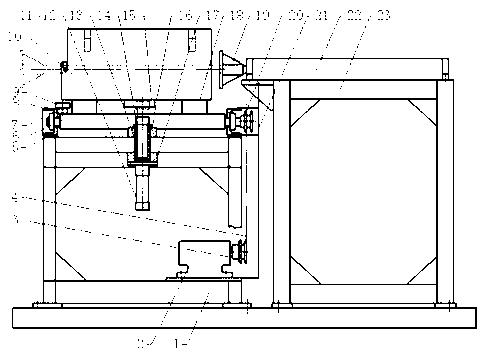

[0027] Embodiment 1: as Figure 1-6 As shown, the sponge cadmium cake smelting automatic feeding machine is composed of a conveying positioning device, a conveying material box and a pushing device. The conveying material box is installed on the upper end of the conveying positioning device, and the pushing device is installed on one side of the conveying positioning device.

[0028] The conveying and positioning device consists of a frame 1, a reduction motor 2, a sprocket 3, a chain 4, a bearing support 5, a roller 6, a positioning beam 11, a positioning cylinder 12, a linear bearing 13, a positioning shaft 14, and a bearing mounting flange 16. Oil cylinder mounting flange 17 and roller sprocket 20 form. The frame 1 is fixed on the foundation by anchor bolts, and the geared motor 2 is fixed on the frame 1 by bolts. The sprocket 3 is fixed on the output shaft of the reduction motor 2 through a key and connected with the roller sprocket 20 through the chain 4. The roller spr...

Embodiment 2

[0032] Embodiment 2: as Figure 1-6 As shown, the sponge cadmium cake smelting automatic feeding machine is composed of a conveying positioning device, a conveying material box and a pushing device. The conveying material box is installed on the upper end of the conveying positioning device, and the pushing device is installed on one side of the conveying positioning device.

[0033] The conveying and positioning device consists of a frame 1, a reduction motor 2, a sprocket 3, a chain 4, a bearing support 5, a roller 6, a positioning beam 11, a positioning cylinder 12, a linear bearing 13, a positioning shaft 14, and a bearing mounting flange 16. Oil cylinder mounting flange 17 and roller sprocket 20 form. The frame 1 is fixed on the foundation through anchor bolts, and the geared motor 2 is welded on the frame 1 . The sprocket 3 is fixed on the output shaft of the reduction motor 2 through a key and connected with the roller sprocket 20 through the chain 4, the roller sproc...

Embodiment 3

[0036] Embodiment 3: as Figure 1-6 As shown, the sponge cadmium cake smelting automatic feeding machine is composed of a conveying positioning device, a conveying material box and a pushing device. The conveying material box is installed on the upper end of the conveying positioning device, and the pushing device is installed on one side of the conveying positioning device.

[0037] The conveying and positioning device consists of a frame 1, a reduction motor 2, a sprocket 3, a chain 4, a bearing support 5, a roller 6, a positioning beam 11, a positioning cylinder 12, a linear bearing 13, a positioning shaft 14, and a bearing mounting flange 16. Oil cylinder mounting flange 17 and roller sprocket 20 form. The frame 1 is fixed on the foundation, and the geared motor 2 is fixed on the frame 1 by bolts. The sprocket 3 is fixed on the output shaft of the reduction motor 2 through a key and connected with the roller sprocket 20 through the chain 4, the roller sprocket 20 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com