Composite lumbar support device

A technology of composite materials and waist beams, which is applied in construction, excavation, infrastructure engineering, etc., can solve the problems of no patent technology disclosure, no research reports on composite material waist beams, etc., achieve low production costs and reduce large-scale construction The use of hoisting machinery, the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

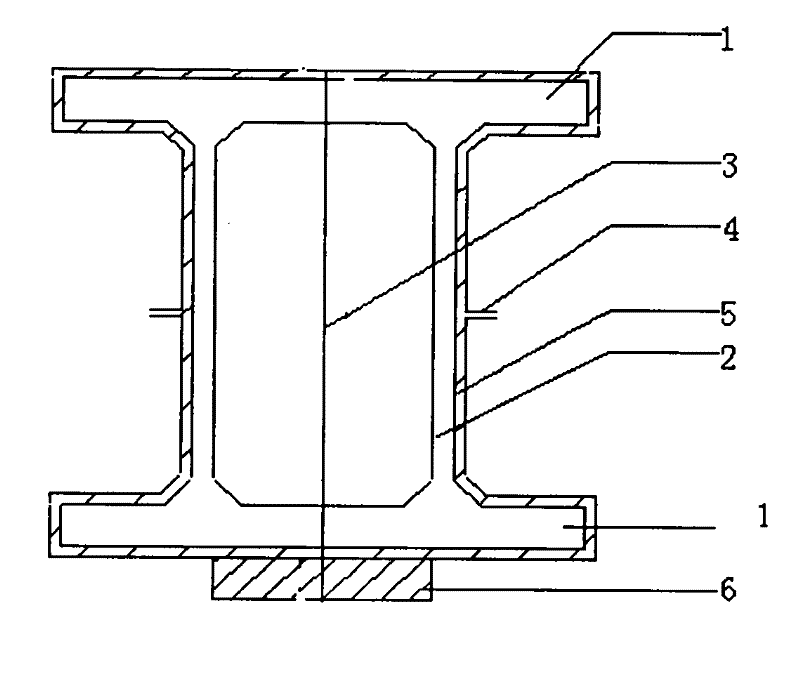

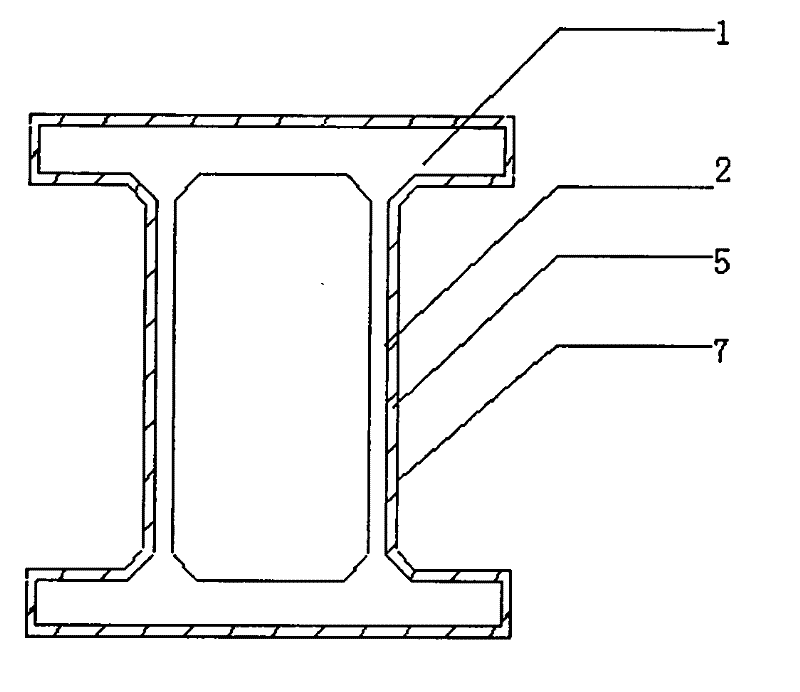

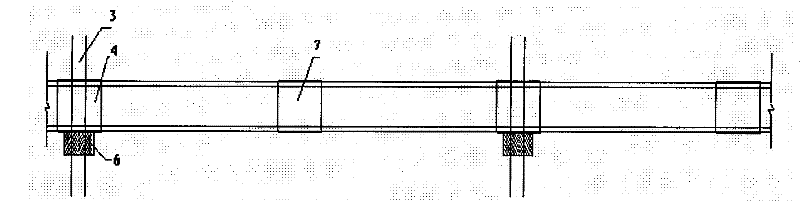

[0012] The main structure of this embodiment includes double web waist beam flange 1, double web waist beam web 2, anchor rod 3, split reinforcement gasket 4, epoxy resin layer 5, connecting member or anchor 6 and connecting member Sleeve 7; the two ends of the two waist beam webs of the symmetrical vertical structure are horizontally formed with double web waist beam flanges 1, and the double web waist beam flanges 1 and the waist beam web are integrated to form an "工" structure; the waist beam wings The edge is divided into upper and lower flanges, and the center of the upper and lower flanges is made with a column type or pipe type anchor rod 3, and the waist beam is connected to the anchor rod 3. The waist beam web 2 and the waist beam flange 1 are surrounded. An epoxy resin layer 5 is coated on the top, and a split reinforcement gasket 4 is made on the outside of the epoxy resin layer 5, which is used for force transmission and reinforcement between the waist beam connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com