Method of making heated glazing

A glass sheet and window technology, applied in the field of heated windows, can solve the problems of polluting the surface of the film, prolonging the deposition time, reducing revenue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

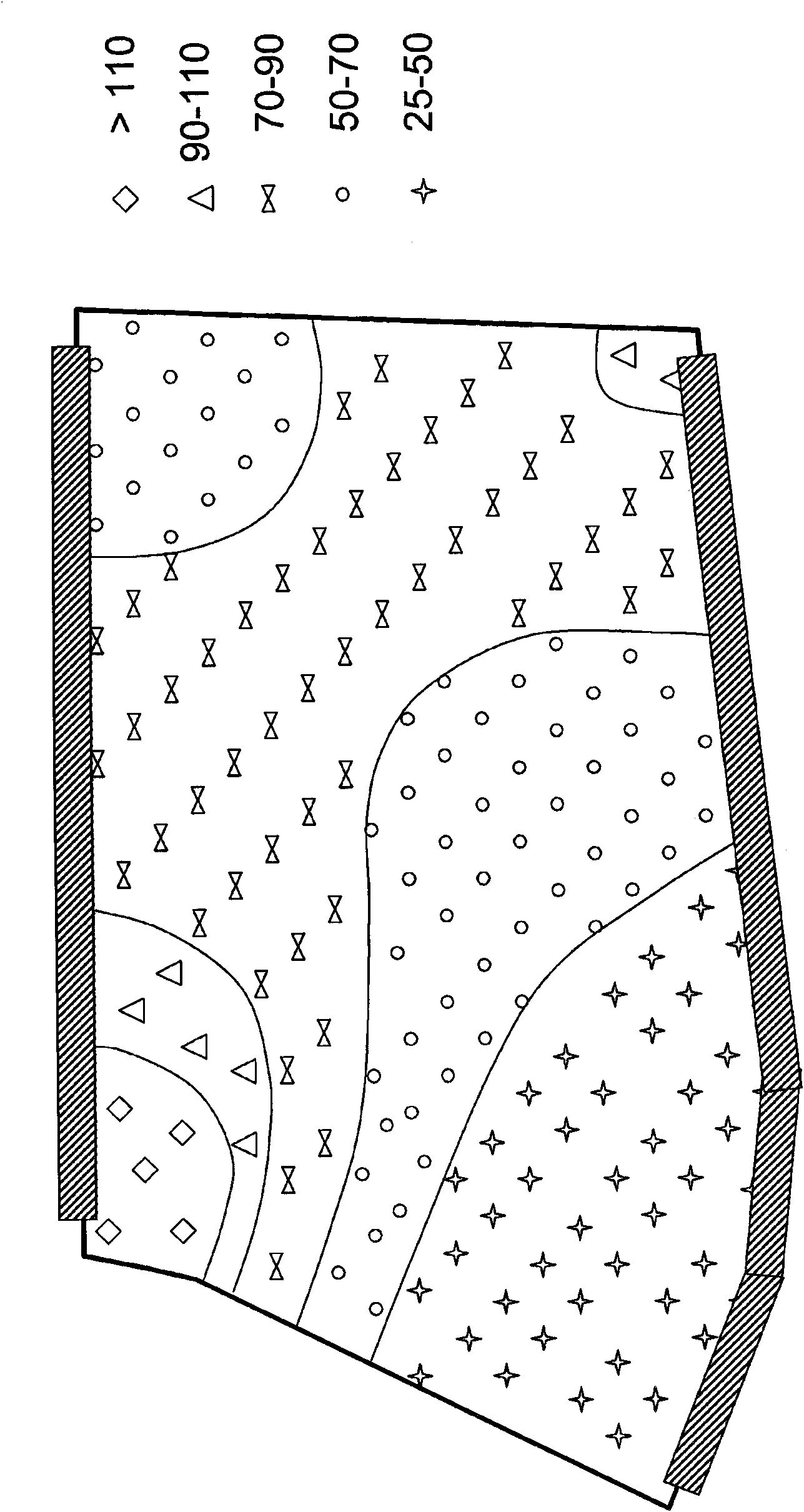

[0058] figure 1 Shown is a schematic diagram of an aircraft window, which includes two wires in the form of conductive strips (marked by dashes in the figure). The heating film made of ITO has uniform sheet resistance over the entire area. As shown, the resulting electrical power density is very non-uniform, relative to the target power density of 70 W / dm 2 , the power density in the lower left corner is about 25W / dm 2 , however the power density in the upper left corner exceeds 100, or even 150W / dm 2 . The ratio K of the average power density to the maximum power density is only 0.3.

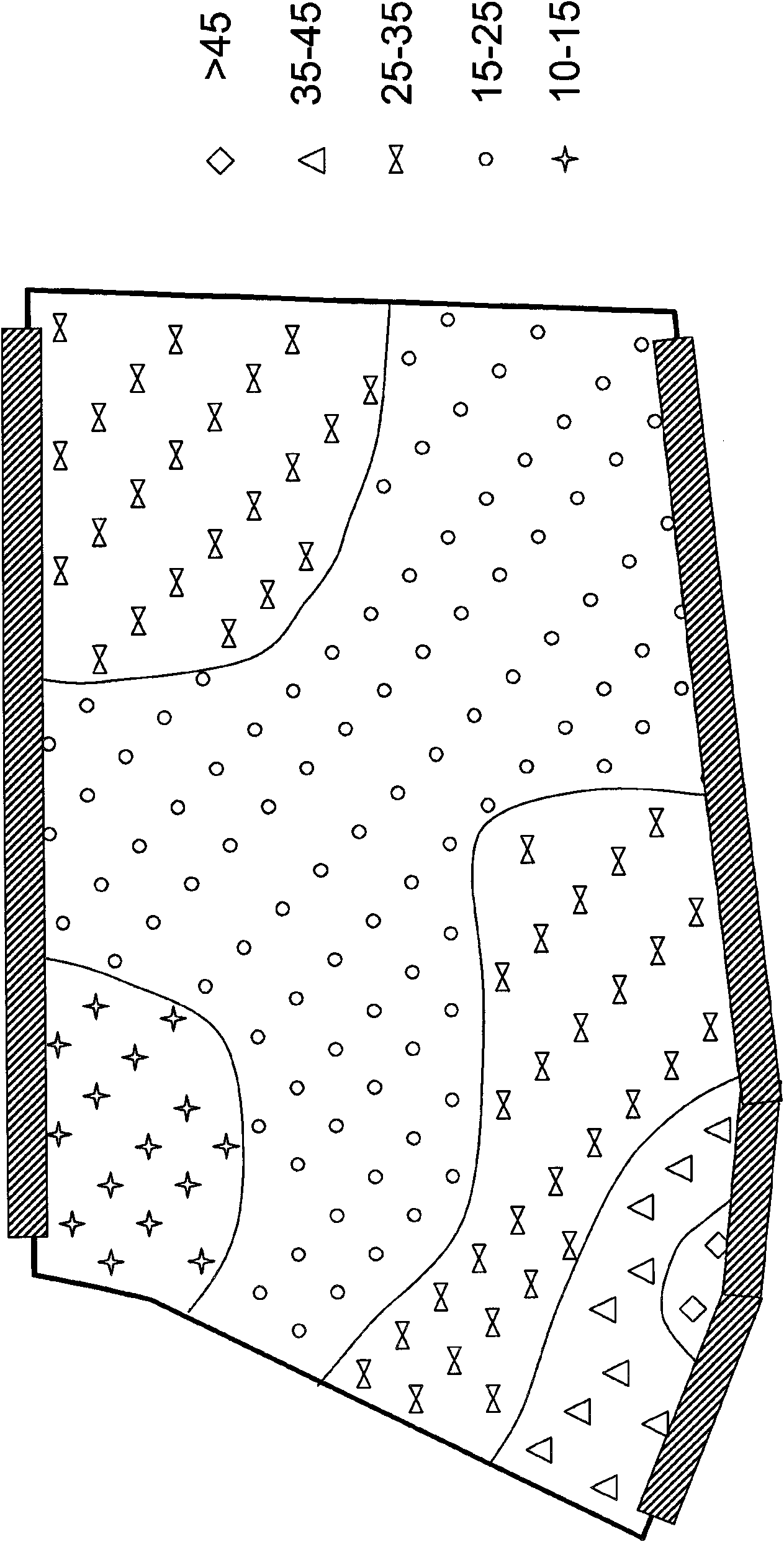

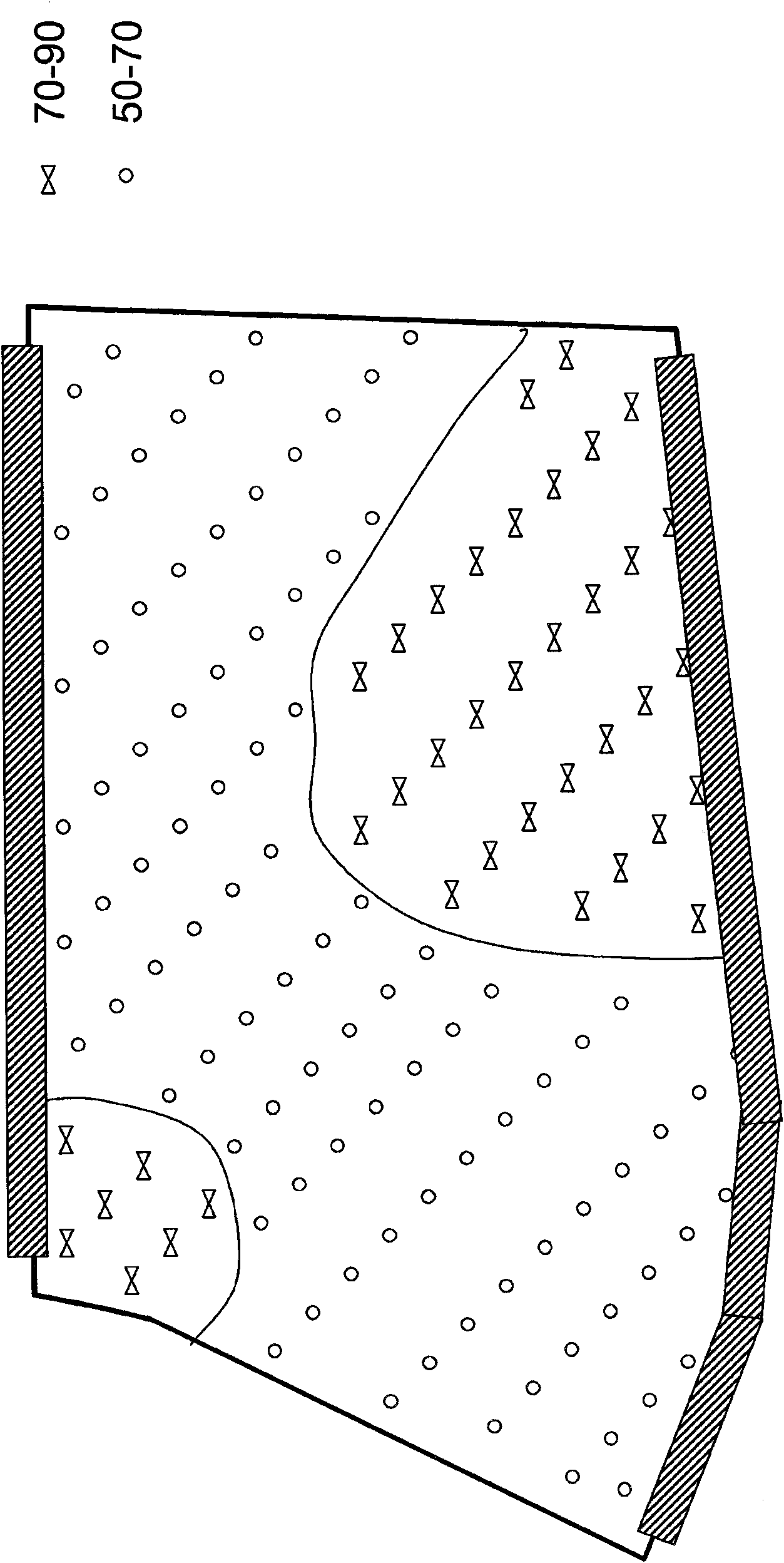

[0059] figure 2 The heated windows in include an ITO film treated in accordance with the present invention with a different sheet resistance in one area than another. The gradient of sheet resistance is represented by contour lines. From about 10 ohms in the upper left corner, to over 30 ohms in sheet resistance in the lower left corner. image 3 Indicates that such a window has a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap