A built-in level gauge for indicating the level of liquid in equipment or containers

A liquid level gauge, built-in technology, applied in the direction of the buoy liquid level indicator, etc., can solve the problems of clutter, steam or electric energy consumption, and achieve the effect of neat appearance, avoiding oil leakage, and no wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

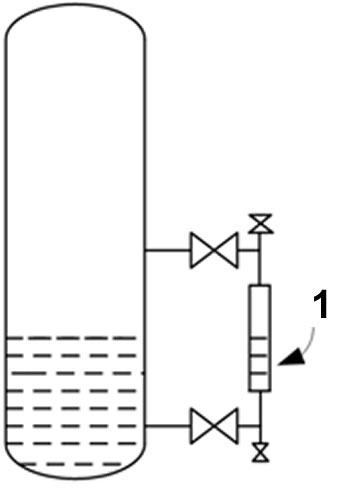

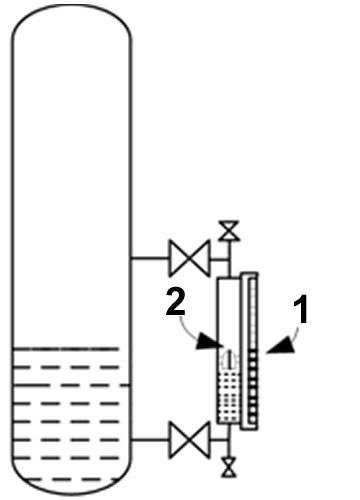

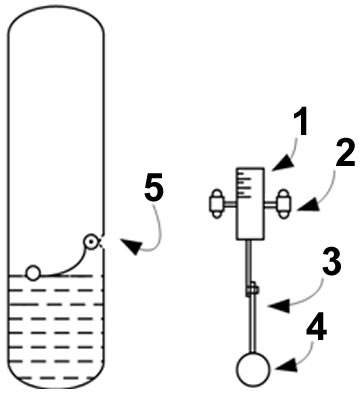

[0018] The liquid level gauge of the present invention is made of floating ball 4, telescopic fixed connecting rod 3, rotating dial 1, bearing support 2 and visible convex lens 5 installed on the container, as image 3 shown. Install the visible convex lens at the proper position of the container, and install the rotating dial through the bearing bracket at the center level of the visible convex lens inside the container. There are threaded holes on the bearing bracket to cooperate with the bolts on the container wall, or directly weld the bracket on the container wall. Then the floating ball is connected with the rotary dial through the telescopic fixed connecting rod, so far a complete built-in liquid level gauge is installed. When the floating ball moves up and down with the liquid level, the floating ball also drives the rotating dial to rotate through the connecting rod. The operator can easily observe the value on the rotating dial through the visible convex lens instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com